Production method for twinning induced plasticity steel of deformed grain/partial re-crystallization structures

A twinning-induced plasticity and recrystallization technology, which is applied in the field of alloy steel processing, can solve the problems of unsatisfactory comprehensive effects, unfavorable energy absorption per unit mass and unfavorable energy absorption efficiency, and achieve improved energy absorption capacity, energy absorption efficiency, and improved plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

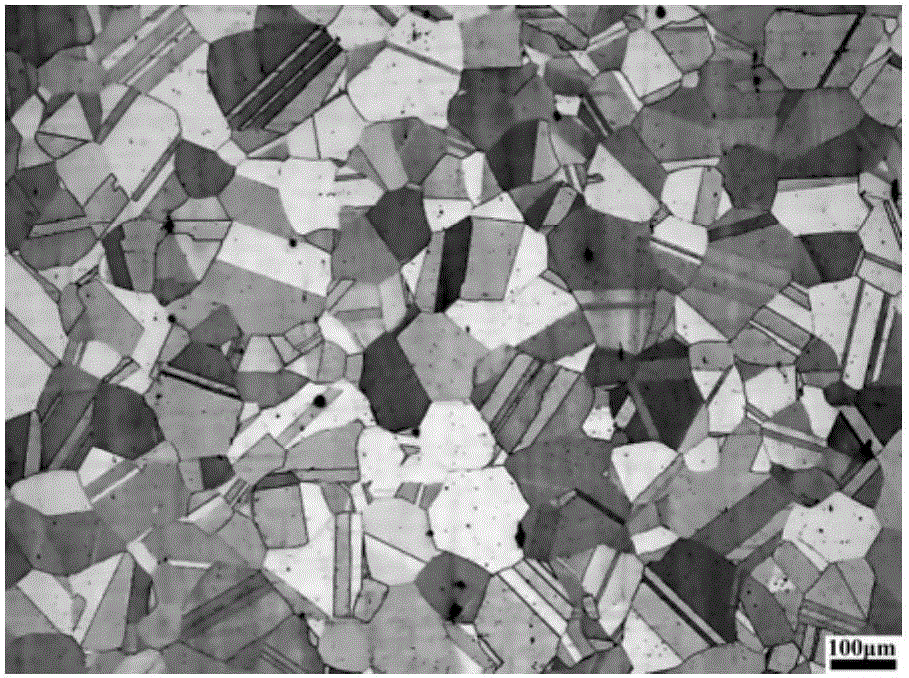

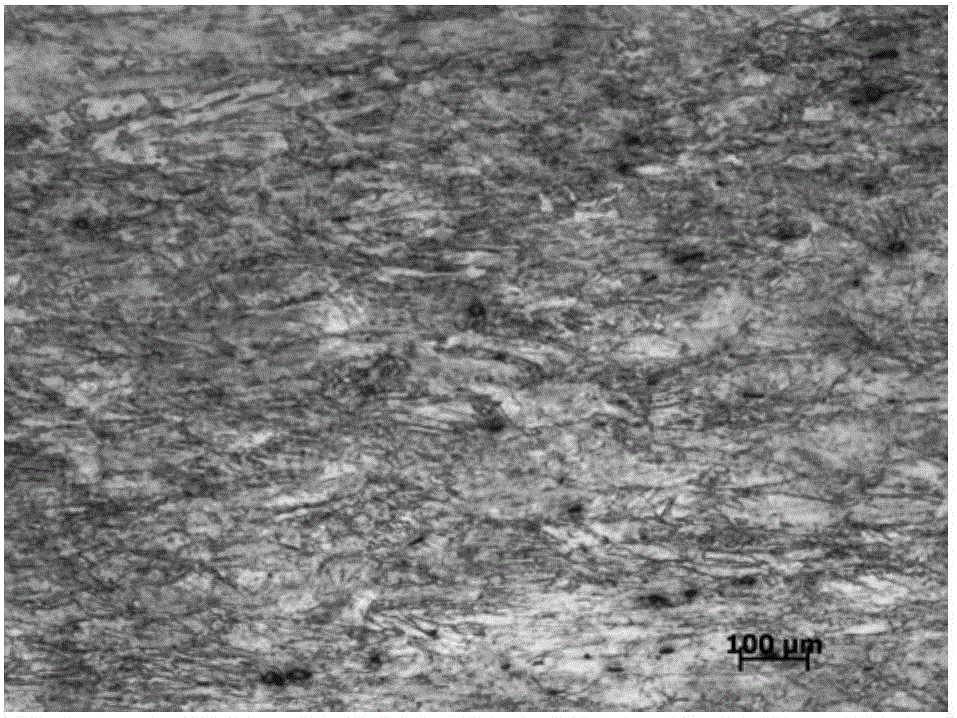

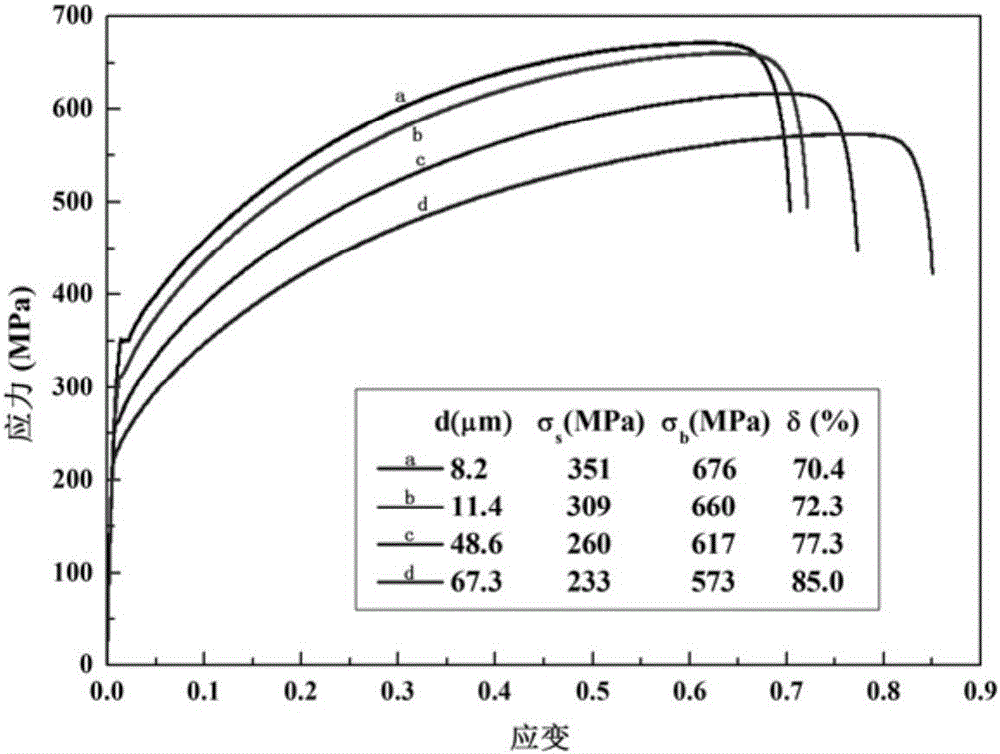

[0026] Embodiment: Twin-induced plasticity steel with high energy absorption capacity, high energy absorption efficiency and high bearing capacity, its main chemical composition is (wt.%): Mn: 29.5; Al: 2.75%; Si: 3.10%; C: 0.05 ; The rest is Fe.

[0027] The preparation method is as follows:

[0028] (1) Dosing according to the target ingredients, smelting in a vacuum induction furnace under the protection of argon, and pouring into steel ingots after smelting;

[0029] (2) The amount of turning on the surface of the steel ingot is 2 mm. After being forged at a high temperature of 1000 ° C, it is drawn and cut to obtain a forging billet with a size of 80 × 80 × 600 mm, and the forging ratio is 0.5;

[0030] (3) Upsetting the high-temperature elongated forging billet at 1000°C to a forging billet with a cross-sectional size of 120×120 mm.

[0031] (4) Elongate the upset forging blank at 650°C to a forging blank with a cross-sectional size of 45×45mm;

[0032] (5) Heat the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation after break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com