Oil and gas pipeline L360M hot-rolled steel coil with low yield ratio and preparation method of oil and gas pipeline L360M hot-rolled steel coil

A low-yield-ratio, hot-rolled steel coil technology, applied in the field of hot-rolled steel coils, can solve the problems of many surface cracks, low cold working performance, poor welding performance, etc., and achieve small performance anisotropy and reduced welding performance , to avoid the effect of yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] ①Ingredient design

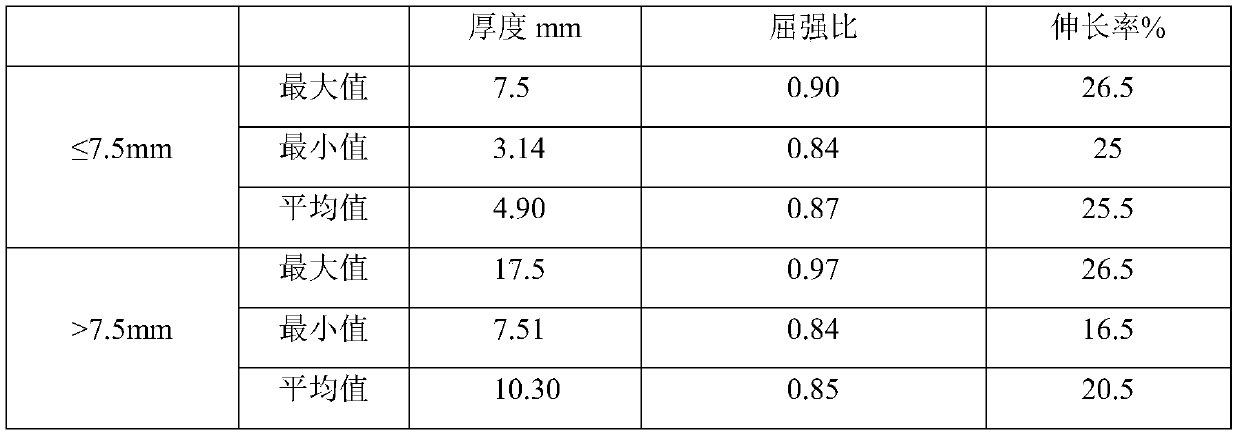

[0029] Table 1 Composition design range

[0030]

[0031] ②Process route:

[0032] Hot metal desulfurization → converter smelting → argon blowing → LF → continuous casting (finishing) → hot continuous rolling → laminar cooling → coiling

[0033] ③Steelmaking

[0034] 180t converter smelting, bottom blowing is controlled by N2 / Ar switching. Tapping time ≥ 4min; tapping with double slag stop, slag thickness ≤ 100mm.

[0035] The argon station (LF) arrives at the station to fix the oxygen, adds aluminum to deoxidize until the free oxygen is not more than 10PPM, and operates the LF furnace to reduce the slag, and the sulfur content of the tapping LF furnace is not more than 0.006%.

[0036] ④Continuous casting

[0037] Liquidus temperature TL = 1521°C; target tundish temperature TL = 20±7°C;

[0038] Mold powder: sub-peritectic steel powder;

[0039] When the tundish is poured in the first furnace of continuous pouring, the tundish covering ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com