A kind of killed steel deoxidation method

A technology for killing steel and tons of steel, which is applied in the field of low-cost refining technology for killed steel deoxidation, can solve problems such as unfavorable submerged arc operation, affecting the economic benefits of enterprises, increasing economic losses of enterprises, and improving the purity of molten steel and casting billet. quality, the effect of reducing the number of eye sets and production accidents, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

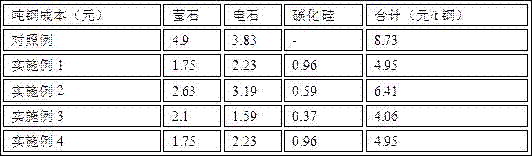

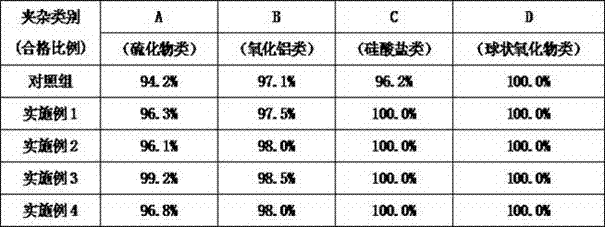

Examples

Embodiment 1

[0029] For Q235B steel, process steps:

[0030] (1) Slag washing is carried out during the tapping process of the converter, and the amount of lime added per ton of steel is 2.4kg; the functions of lime are: ① slagging effect; ② reducing burning loss, and the melt covers the surface of molten steel to prevent excessive oxidation. Through the slag washing of this step, the quality of molten steel can be improved;

[0031] (2) Move the ladle to the refining treatment position, the refining start temperature is 1560°C, the amount of lime added per ton of steel is 4.0kg, the amount of fluorite added per ton of steel is 1.0kg, and the feeding time is 2min. The flow rate is 200NL / min; in the process of adding lime to make slag in this step, there must be a relatively large argon blowing pressure to ensure that the added lime is completely spread on the surface of the ladle, and to ensure that the slag-making material does not accumulate on the side of the feeding hole. White slag p...

Embodiment 2

[0038] For Q345B steel, process steps:

[0039] (1) Slag washing is carried out during the tapping process of the converter, and the amount of lime added per ton of steel is 2.6kg;

[0040] (2) Move the ladle to the refining treatment position, the refining start temperature is 1580°C, the amount of lime added per ton of steel is 6.0kg, the amount of fluorite added per ton of steel is 1.5kg, the feeding time is 3min and the lime time is 1.5min. Stirring with argon, the flow rate of argon is 300NL / min;

[0041] (3) Power transmission and slag operation, the secondary voltage of the transformer is maintained at 278V, and the flow rate of argon gas is 130NL / min;

[0042] (4) After the slag is completely melted and thoroughly deoxidized, the order of adding the deoxidizer is to add silicon carbide first and then calcium carbide, the amount of silicon carbide added per ton of steel is 0.4kg, the amount of calcium carbide added per ton of steel is 1.0kg, and the slag sample is yell...

Embodiment 3

[0046] For A36B steel, process steps:

[0047] (1) Slag washing is carried out during the tapping process of the converter, and the amount of lime added per ton of steel is 2.5kg;

[0048] (2) Move the ladle to the refining treatment position, the refining start temperature is 1520°C, the amount of lime added per ton of steel is 5.0kg, the amount of fluorite added per ton of steel is 1.2kg, and the feeding time is 3min. The flow rate is 240NL / min;

[0049] (3) Power transmission and slag operation, the secondary voltage of the transformer is maintained at 313V, and the flow rate of argon gas is 140 NL / min;

[0050] (4) Deoxidize after the slag has been fully melted and thoroughly deoxidized. The order of adding the deoxidizer is to add silicon carbide first and then calcium carbide. The amount of silicon carbide added per ton of steel is 0.25kg, and the amount of calcium carbide added per ton of steel is 0.5kg. The slag sample is yellow and white slag; The accumulated amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com