Production process of hollow steel for rock drilling tool

A production process and drilling tool technology, which is applied in the production process field of hollow steel for rock drilling tools, to achieve the effects of increasing service life, reducing scrap rate, and improving as-cast structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

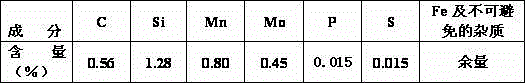

[0020] Example 1. The main chemical composition of hollow steel 55SiMnMo for rock drilling tools is shown in Table 1 by weight percentage:

[0021] Table I

[0022]

[0023] The steel is tapped in an ultra-high power 60t eccentric bottom tapping electric arc furnace with a Consid continuous feeding system. After being refined and reduced in a 60tLF furnace, it is then subjected to VD degassing treatment for 25 minutes; after the VD degassing treatment, argon pressure of 0.28MPa is used. , The flow rate is 90NL / min, and the cover is soft blown for 9 minutes. After calcium treatment, the argon pressure is 0.25MPa, and the flow rate is 65NL / min. The continuous casting machine, the superheat is controlled at 30±5°C, the casting speed is controlled at 1.95-2.30m / min, the tundish baking temperature is 1150°C, the mold liquid level is automatically controlled, with electromagnetic stirring and full protection casting; casting The billet adopts the "steel pusher type slow c...

Embodiment 2

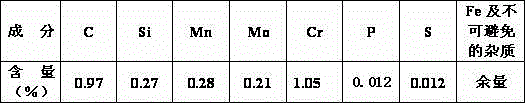

[0025] Embodiment 2: Hollow steel 95CrMo for rock drilling tools. By weight percentage, its main chemical composition is as shown in Table 2:

[0026] Table II

[0027]

[0028] Process control: use the ultra-high power 60t eccentric bottom tapping electric arc furnace with Consdie continuous feeding system to tap steel, after refining and reducing in 60tLF furnace, then go through VD degassing treatment for 30min; after VD degassing treatment, use argon Air pressure 0.28MPa, flow rate 90NL / min for 9 minutes of soft blowing with the lid closed, after calcium treatment, use argon pressure 0.25MPa, flow rate 65NL / min for soft blowing for 12 minutes, then hang the bag to the continuous casting machine for casting; the continuous casting process uses For a continuous casting machine with a cross-section of 150mm×150mm, the superheat is controlled at 30±5°C, the casting speed is controlled at 1.95-2.30m / min, the tundish baking temperature is 1150°C, the mold liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com