Efficient co-production strategy of L-phenylglycine and gluconic acid

A technology of gluconic acid and phenylglycine, applied in the field of microorganisms, can solve the problems of long fermentation time, strict control of fermentation conditions, low energy consumption, etc., and achieve the effect of fast and efficient conversion process and important industrial application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of Escherichia coli Competent and Transformation of Plasmid

[0040] [1] Preparation of competent Escherichia coli. Activate the monoclonal Escherichia coli in 10ml LB medium, then transfer to 37°C shaking culture to OD 600 0.35 to prepare the competent state; put the cultured bacterial solution in ice water, shake gently to cool the bacterial solution for about 10 minutes; prepare several 1.5ml centrifuge tubes for sterilization, and divide the bacterial solution into the tubes, The amount of bacteria in the tube is 1.2ml, put the centrifuge tube in ice; centrifuge the bacteria solution at 8000r / min for 10-20s, let it stand in ice water for 2min, discard the supernatant, add pre-cooled 0.1M CaCl 2 400μL, gently blow the suspension, put it in ice for 15min (repeat this step 2-3 times); finally, add pre-cooled 0.1M CaCl 2 80 μL, gently pipette the suspension and place it on ice.

[0041] [2] Transformation of plasmids. Take the competent cel...

Embodiment 2

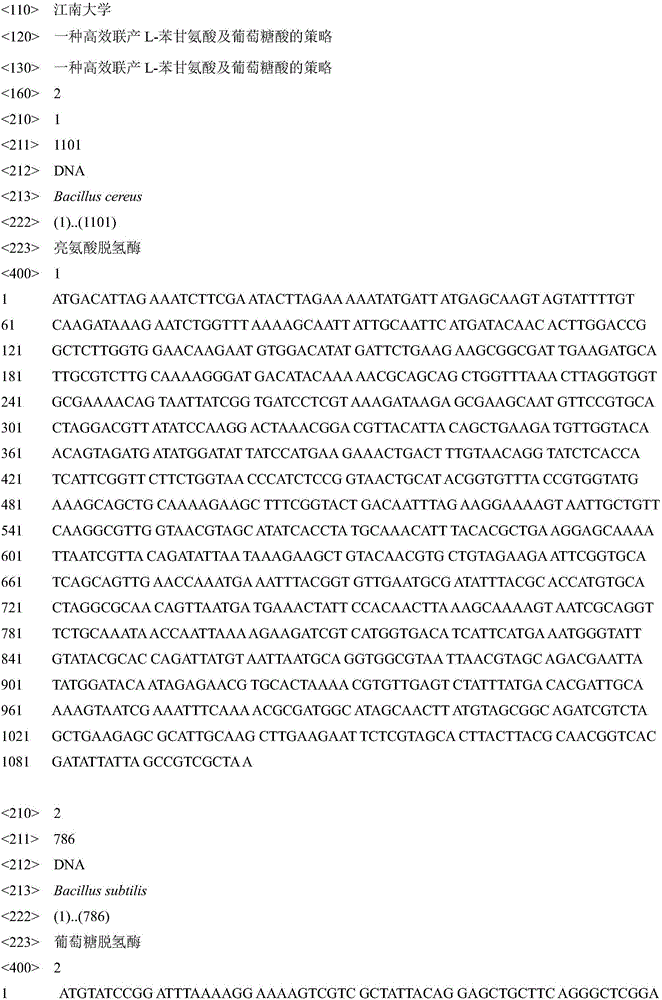

[0042] Example 2: Construction and transformation of recombinant plasmid pET-28a-Bsleudh / pET-28a-Bcleudh / pET-28a-Blleudh / pET-28a-Baleudh / pET-28a-Heleudh / pET-28a-Nmleudh

[0043] [1] Genomic DNA of Bacillus subtilis, Bacillus cereus, Bacillus licheniformis, Bacillus amyloliquefaciens, Halomonas longum and halophilic archaea were used as templates.

[0044] [2] According to the L-leucine dehydrogenase gene sequence of Bacillus subtilis, Bacillus cereus, Bacillus licheniformis, Bacillus amyloliquefaciens, Halomonas longum and halophilic archaea and the pET-28a plasmid Design the primers of leudh gene according to the restriction site.

[0045] PBsldhF: CGGGATCCATGGAACTTTTTAAATATATG (BamHI)

[0046] PBsldhR: CCCAAGCTT TTAACGTCTGCTTAATACACTGT (HindIII)

[0047] PBcldhF: CGGGATCCATGACATTAGAAATCTTCGA (BamHI)

[0048] PBcldhR: CCCTCGAGTTAGCGACGGCTAATAATATCG(XhoI)

[0049] PBlldhF: CGGGATCCATGGAACTATTTCGATATATGGA (BamHI)

[0050] PBlldhR: CCCAAGCTT TTAACGTCTGCTTAAAATGTGA (HindIII)...

Embodiment 3

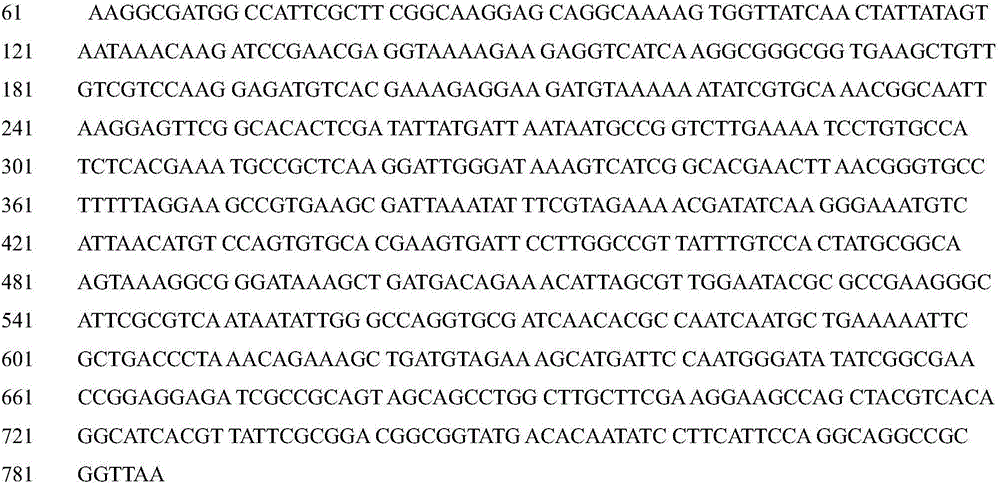

[0060] Example 3: Construction and transformation of recombinant plasmid pET-28a-Bmgdh / pET-28a-Bsgdh / pET-28a-Btgdh

[0061] [1] Genomic DNA of Bacillus megaterium, Bacillus subtilis and Bacillus thuringiensis were used as templates.

[0062] [2] Design gdh gene primers based on the glucose dehydrogenase gene sequences of Bacillus megaterium, Bacillus subtilis and Bacillus thuringiensis and the restriction sites on the pET-28a plasmid.

[0063] PBmgdhF: CGGAATTCATGTATACAGATTTAAAAGATA (EcoRI)

[0064] PBmgdhR: CCCAAGCTTTTAACCTCTTCCCGCTTGGAAAG (HindIII)

[0065] PBsgdhF: CGGAATTCATGTATCCGGATTTAAAAGGAAA (EcoRI)

[0066] PBsgdhR: CCCAAGCTTTTAACCGCGGCCTGCCTGGAAT (HindIII)

[0067] PBtgdhF: CGGAATTCATGTATAGTGATTTAGAAGGAA (EcoRI)

[0068] PBtgdhR: CCCAAGCTTTTACCCCACGTCCAGCTTGAAAC (HindIII)

[0069] [3] Using the genomic DNA of Bacillus megaterium, Bacillus subtilis and Bacillus thuringiensis as templates, the gdh gene was amplified by PCR. PCR amplification system: template 2 μL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com