A kind of sintering method of cobalt-free tungsten carbide

A sintering method and cobalt tungsten carbide technology are applied in the sintering of cobalt-free tungsten carbide and tungsten carbide sintering process, which can solve the problems of material densification, sintering performance influence, and high sintering temperature when the sintering temperature is increased, and the sintering temperature can be reduced. , The effect of high density and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

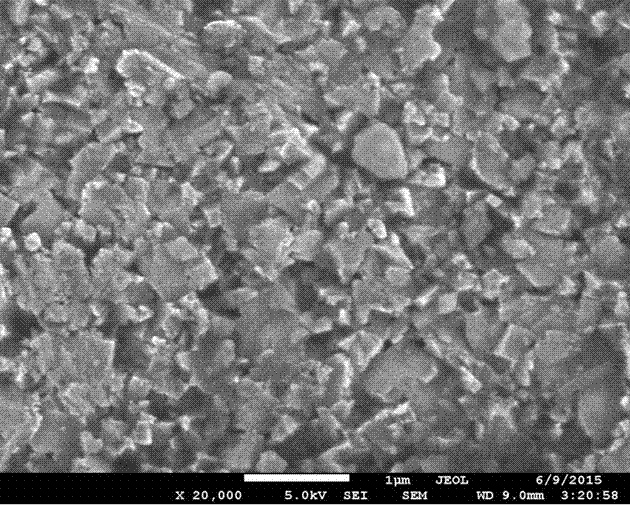

Image

Examples

Embodiment 1

[0022] (1) Ingredients: Prepare WC powder with a graphene content of 0.2w%. Put 49.9g of nano-WC powder and 0.1g of graphene into a ball mill, add an appropriate amount of alcohol, set the rotation speed at 400 rad / min, take out the slurry after 48 hours, put it in an oven, bake at 90°C for 24 hours, and pass through a 100-mesh screen.

[0023] (2) Firing: Take an appropriate amount of the above-mentioned dried powder and put it into a graphite mold with an internal diameter of 20mm for compaction, and place it together with the mold between the upper and lower electrodes of the SPS device, and draw a vacuum (to make the vacuum degree reach 6Pa) After power on, heat up and pressurize at a rate of 200°C / min to reach a sintering temperature of 1700°C. The axial pressure is 50MPa and then keep warm for 5 minutes. After power off and cooling, the sample is taken out.

[0024] (3) Cleaning: Grinding and cleaning the products after they are released from the furnace to remove the ca...

Embodiment 2

[0027] (1) Ingredients: Prepare WC powder with a graphene content of 0.4w%. Put 49.8g of nano-WC powder and 0.2g of graphene into a ball mill, add an appropriate amount of alcohol, set the rotation speed at 400 rad / min, take out the slurry after 48 hours, put it in an oven, bake at 90°C for 24 hours, and pass through a 100-mesh screen.

[0028] (2) Firing: Take an appropriate amount of the above-mentioned dried powder and put it into a graphite mold with an internal diameter of 20mm for compaction, and place it together with the mold between the upper and lower electrodes of the SPS device, and draw a vacuum (to make the vacuum degree reach 6Pa) After power on, heat up and pressurize at a rate of 200°C / min to reach the sintering temperature of 1590°C, keep the temperature for 5 minutes after the axial pressure is 50MPa, and take out the sample after power off and cooling.

[0029] (3) Cleaning: Grinding and cleaning the products after they are released from the furnace to remo...

Embodiment 3

[0032] (1) Ingredients: Prepare WC powder with a graphene content of 0.6w%. Put 49.7g of nano-WC powder and 0.3g of graphene into a ball mill, add an appropriate amount of alcohol, set the rotation speed at 400 rad / min, take out the slurry after 48 hours, put it in an oven, bake at 90°C for 24 hours, and pass through a 100-mesh screen.

[0033] (2) Firing: Take an appropriate amount of the above-mentioned dried powder and put it into a graphite mold with an internal diameter of 20mm for compaction, and place it together with the mold between the upper and lower electrodes of the SPS device, and draw a vacuum (to make the vacuum degree reach 6Pa) After power on, heat up and pressurize at a rate of 200°C / min to reach a sintering temperature of 1500°C. The axial pressure is 50MPa and then keep warm for 5 minutes. Take out the sample after power off and cooling.

[0034] (3) Cleaning: Grinding and cleaning the products after they are released from the furnace to remove the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com