Novel cut-resistant yarn and production method of cut-resistant articles of novel cut-resistance yarn

A yarn, a new technology, applied in the field of preparation of new cut-resistant yarn and its cut-resistant products, can solve the problems of no electromagnetic shielding performance, poor flame retardancy, poor flexibility, low linear density, etc., and achieve good cut resistance, Excellent flexibility and wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

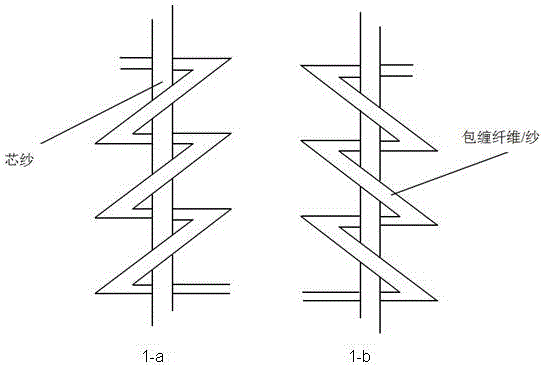

[0032] The preparation method of this novel cut-resistant yarn uses high-strength and high-count tungsten filament yarn as the core yarn, wraps the core yarn with wrapping fiber / yarn, and weaves it into a new cut-resistant yarn through a spinning process Wherein, the number of the core yarn is 3-250tex, the tungsten yarn accounts for 20%-80% of the total weight of the novel anti-cut yarn by weight percentage, and the spinning process is air-jet vortex spinning, One of various processing methods such as friction spinning and rotor spinning. The number of the core yarn is 10-230, preferably 30-200, more preferably 50-150; more preferably 80-120; the tungsten yarn accounts for the total weight of the novel cut-resistant yarn by weight percentage 25%-70%, preferably 30%-60%, preferably 35%-50%, more preferably 40%-45%.

[0033] The tungsten yarn used in the present invention is pure tungsten wire, tungsten wire etched on the surface, boron-carbon doped tungsten wire, aluminum oxi...

Embodiment 1

[0039] Embodiment 1 Preparation of cut-resistant gloves

[0040] Step 1, preparation of novel cut-resistant yarn

[0041] The 60tex boron-doped tungsten filament without false twist processing is used as the core yarn of the X yarn; the aramid fiber with a nominal length of 36mm and a fineness of 8tex is used as the wrapping yarn, and is spun by friction spinning;

[0042] The basic spinning unit of friction spinning is mainly composed of the following process parts: 1) Fiber sliver feeding and carding part; 2) Spinning dust cage and suction part; 3) Core yarn feeding part; 4) Yarn drawing and coiling part;

[0043] The following briefly introduces the situation of each part:

[0044] 5 aramid fiber strips are fed in parallel to the working area of the opening roller, the fiber strips are carded into a single fiber state, and reach the working area of the spinning dust cage under the action of centrifugal force and airflow, and the feeding is controlled by the guide roll...

Embodiment 2

[0051] Embodiment 2 Preparation of cut-resistant gloves

[0052] Step 1, preparation of novel cut-resistant yarn

[0053] The 80tex pure tungsten filament without false twist processing is used as the core yarn of the X yarn, the cotton fiber with a nominal length of 48mm and a fineness of 18tex is used as the wrapping yarn, and is spun by friction spinning technology. The basic spinning unit of friction spinning is mainly composed of the following process parts: 1) Fiber sliver feeding and carding part; 2) Spinning dust cage and suction part; 3) Core yarn feeding part; 4) Yarn drawing and coiling part;

[0054] The following briefly introduces the situation of each part:

[0055] 5 cotton fiber slivers are fed in parallel to the working area of the opening roller, the fiber slivers are carded into single fibers, and under the action of centrifugal force and airflow, they reach the working area of the spinning dust cage, and at the same time, they are fed into a single f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com