Flexible Array Reference Electrode and Its Method for In-Situ Study of Metal Weld Corrosion

A flexible array and reference electrode technology, applied in the direction of material electrochemical variables, material analysis through electromagnetic means, instruments, etc., can solve non-destructive and sensitive and accurate detection and evaluation, can not adapt to different surface shapes of welded parts, can not be welded In-situ seam corrosion and other problems, to achieve the effect of low cost, excellent high and low temperature resistance, and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

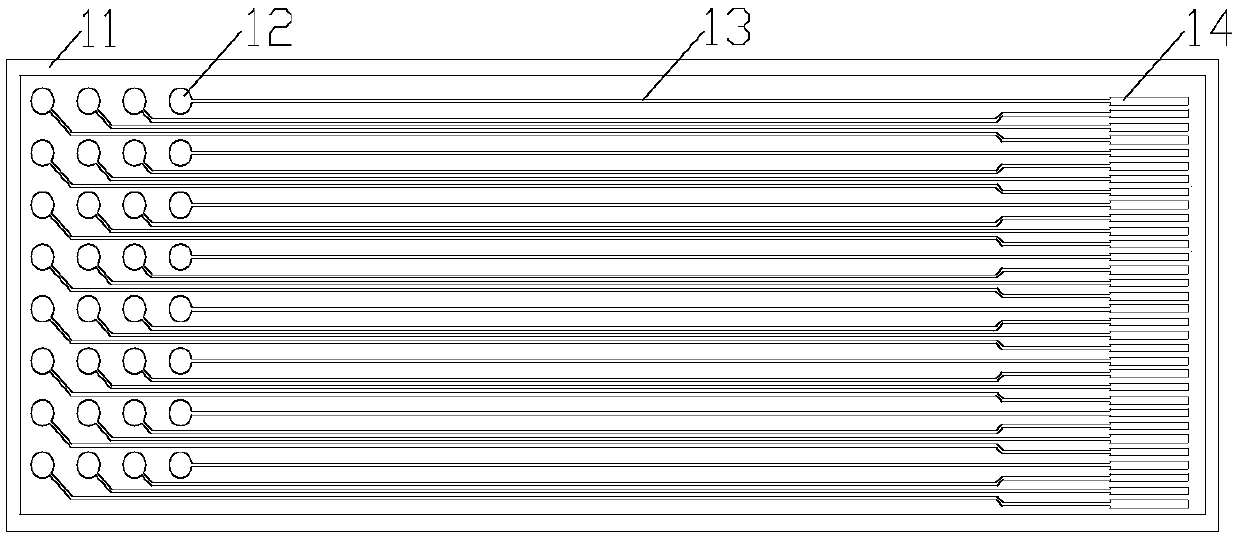

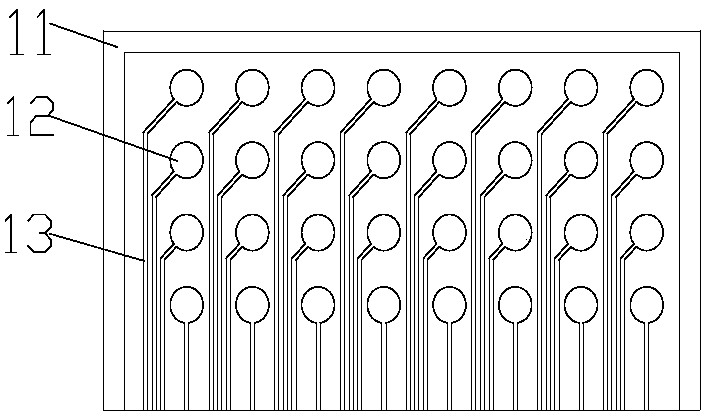

[0034] Such as figure 1 and figure 2 As shown, a flexible array electrode 1 for in-situ detection of metal weld corrosion consists of a flexible substrate 11, an array electrode 12 arranged on the surface of the flexible substrate 11, and is packaged in the flexible substrate 11 and connected with the array electrode 12 connected lead wires 13, the array electrode 12 is made of Ag / AgCl microelectrode array.

[0035] The preparation method of the flexible array reference electrode is as follows:

[0036] Print electrode cores and lead wires 13 on a flexible substrate by means of an adhesive-free flexible printed circuit board. The diameter of the electrode cores is 0.2-2mm, and the interval between each electrode is 0.5-4mm. , tin, silver, gold and other metals, its thickness is 1 / 3-2OZ, the spacing is 0.075-2mm, it is neatly and orderly packaged in the flexible substrate 11, and the end of the lead wire 13 forms a lead wire Interface 14, the lead wire spacing at the lead w...

Embodiment 2

[0041] Prepare flexible array electrodes according to the structure and preparation method described in Example 1, wherein the substrate material is polyimide, the thickness is 0.1mm, the size is 2cm×6cm, and the substrate surface array has 4×8 diameters of 1mm Ag / AgCl microelectrode, the interval between each electrode is 2mm; the thickness of the lead wire is 1 / 2OZ, the lead wire spacing at the lead wire interface is 0.5mm, and the 6mm interface is reinforced with PI.

[0042] When electroplating the silver film, adjust the pH to 10 with potassium hydroxide at 0.5A / dm 2Constant-current silver plating was carried out for 2 hours at a constant current; during anodic chlorination, the concentration of the HCl solution was 0.1mol / L, and a constant-current anodic chlorination was carried out at a current of 0.1mA / cm for 6 hours.

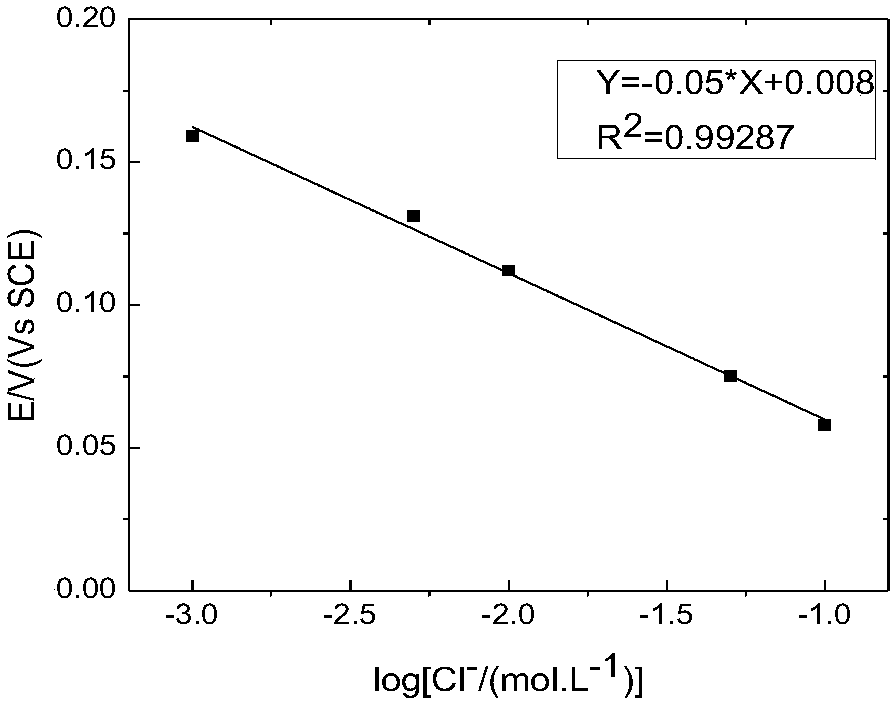

[0043] Such as image 3 As shown, the prepared Ag / AgCl microelectrode has a good linear response in the range of chloride ion concentration 0.001-0.1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com