Mask for fixing conductive ball and manufacturing method thereof

A manufacturing method and technology of conductive balls, applied in the field of masks, can solve the problems of insufficient mechanical strength or chemical resistance, large thickness deviation of spacers, unstable precipitation of electroplating, etc. Deformation and reduction of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

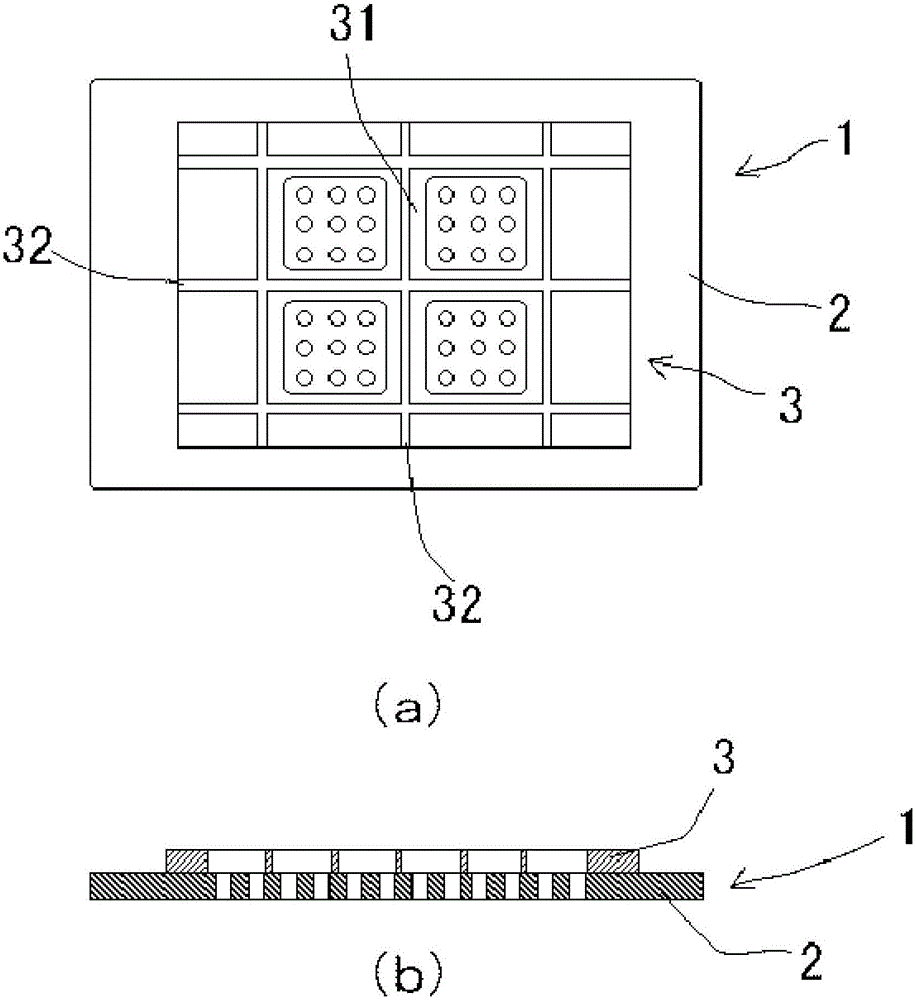

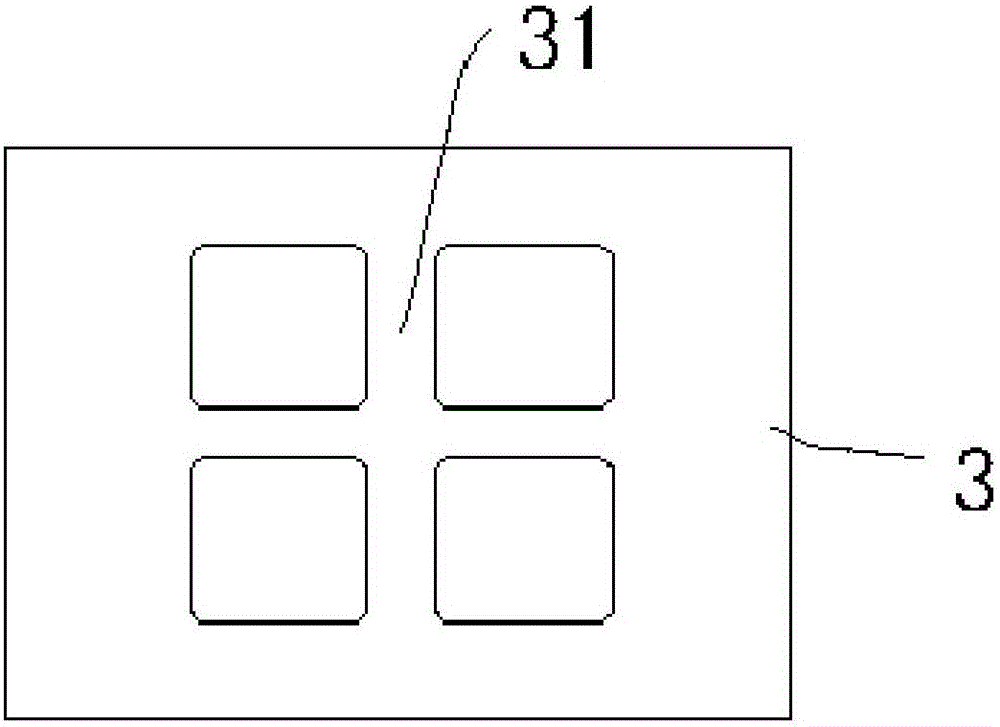

[0041]figure 1 It is a front view (a) and a cross-sectional view (b) of the conductive ball fixing mask 1 of the embodiment. First, the conductive ball fixing mask 1 roughly includes a metal mask (mask) 2 and a resin sheet (sheet) 3, and the metal mask 2 and the resin sheet 3 are bonded by an adhesive sheet (not shown).

[0042] The metal mask 2 is made of a metal thin plate such as nickel or stainless steel, and generally has a thickness of 0.015 mm to 0.2 mm, and an external dimension of a quadrilateral (square or rectangular) with a side of 100 mm to 600 mm. Here, the manufacturing method of the metal mask 2 includes an electrolytic plating method, an etching method, a laser processing method, etc. as described later, but any of them may be used in this embodiment.

[0043] In the surface of the metal mask 2, in order to allow conductive balls to penetrate, a plurality of The through hole is the opening 21. Here, in order to allow the conductive balls to be smoothly inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com