High-adhesive two-component epoxy-polyurethane blend material and its preparation method

A two-component, polyurethane technology, applied in the field of two-component epoxy-polyurethane blend materials and its preparation, can solve the problem that the mechanical properties, compressive strength and bonding strength are not as good as epoxy resin grouting materials, high construction cost, and use Poor durability and other problems, to achieve the effect of excellent comprehensive mechanical properties, excellent comprehensive mechanical properties, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Component B: calculated by mass ratio: polyphenyl polymethylene polyisocyanate: epoxy resin = 5: 1;

[0047] The amount of dual catalysts for foaming and epoxy curing accounted for 8.33% of the epoxy resin;

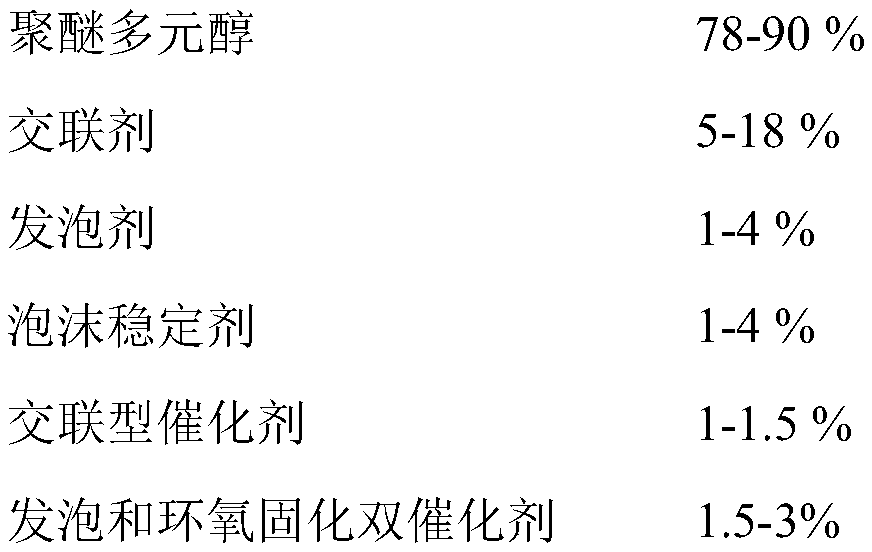

[0048] The composition of the weight percentage of A component:

[0049]

[0050] Among them: polyether polyol adopts polyether JH-4110, crosslinking agent adopts crosslinking agent JH-403, foaming agent is water, foam stabilizer is AK-8805, crosslinking catalyst is stannous octoate, foaming and The epoxy curing dual catalyst is DMEA;

[0051] B component:

[0052] The polyphenyl polymethylene polyisocyanate adopts polyphenyl polymethylene isocyanate (PAPI), and the epoxy resin adopts epoxy resin E-54;

[0053] The preparation method comprises the following steps:

[0054] In the reaction kettle equipped with condenser and agitator, mix polyether JH-4110 and crosslinking agent JH-403, start stirring evenly and heat up to 40°C, then add water, AK-8805, stannous...

Embodiment 2

[0059] Component B: calculated by mass ratio: polyphenyl polymethylene polyisocyanate: epoxy resin = 4: 1;

[0060] The amount of foaming and epoxy curing dual catalysts accounts for 6.67% of the epoxy resin;

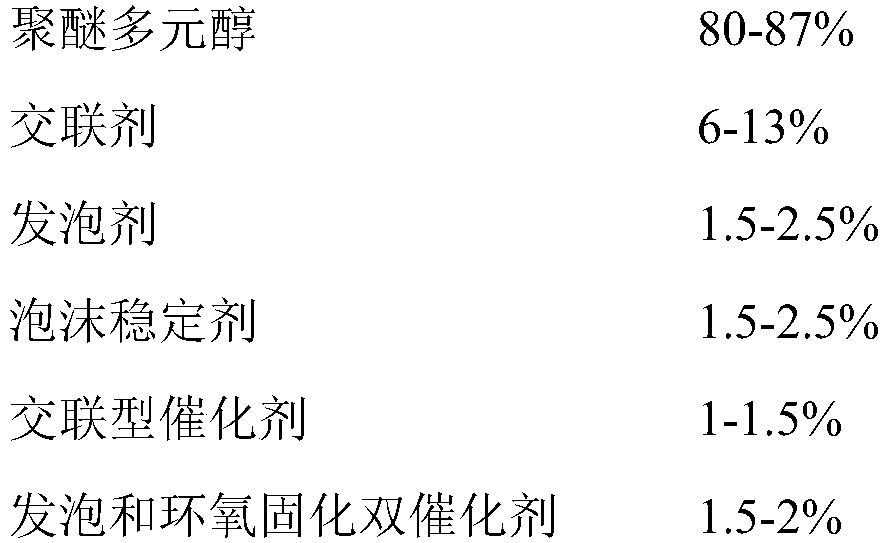

[0061] The composition of the weight percentage of A component:

[0062]

[0063] Among them: polyether polyol adopts polyether JH-4110, cross-linking agent adopts cross-linking agent JH-403, foaming agent is water, foam stabilizer is AK-8805, cross-linking catalyst is dibutyltin dilaurate, hair Foam and epoxy curing dual catalyst is BDMA;

[0064] B component:

[0065] The polyphenyl polymethylene polyisocyanate adopts polyphenyl polymethylene isocyanate (PAPI), and the epoxy resin adopts epoxy resin E-54;

[0066] The preparation method comprises the following steps:

[0067] In the reaction kettle equipped with condenser and agitator, mix polyether JH-4110 and crosslinking agent JH-403, start stirring evenly and heat up to 60°C, then add water, AK-8805, dilaur...

Embodiment 3

[0072] Component B: calculated by mass ratio: polyphenyl polymethylene polyisocyanate: epoxy resin = 6: 1;

[0073] The amount of foaming and epoxy curing double catalyst accounts for 10% of the epoxy resin;

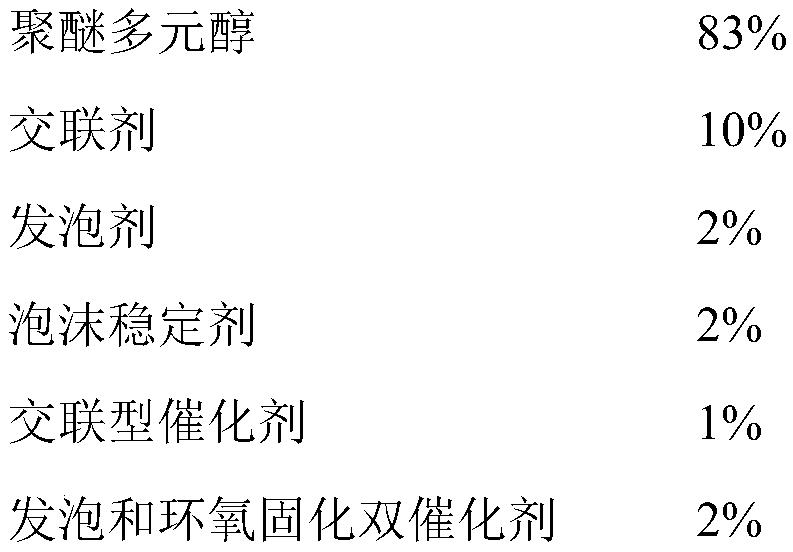

[0074] The composition of the weight percentage of A component:

[0075]

[0076]

[0077] Among them: polyether polyol adopts polyether JH-4110, cross-linking agent adopts cross-linking agent JH-403, foaming agent is water, foam stabilizer is AK-8805, cross-linking catalyst is dibutyltin dilaurate, hair Foam and epoxy curing dual catalyst is DEA;

[0078] B component:

[0079] The polyphenyl polymethylene polyisocyanate adopts polyphenyl polymethylene isocyanate (PAPI), and the epoxy resin adopts epoxy resin E-54;

[0080] The preparation method comprises the following steps:

[0081] In the reaction kettle equipped with condenser and agitator, mix polyether JH-4110 and crosslinking agent JH-403, start stirring evenly and heat up to 80°C, then add water, AK-88...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com