Cold core box binder and casting molding body

A technology of binder and cold core box, which is used in casting molding equipment, casting molds, cores, etc., can solve the problems of reduced production efficiency, incomplete decomposition, low sand core strength, etc., to improve production efficiency and improve normal temperature. performance, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

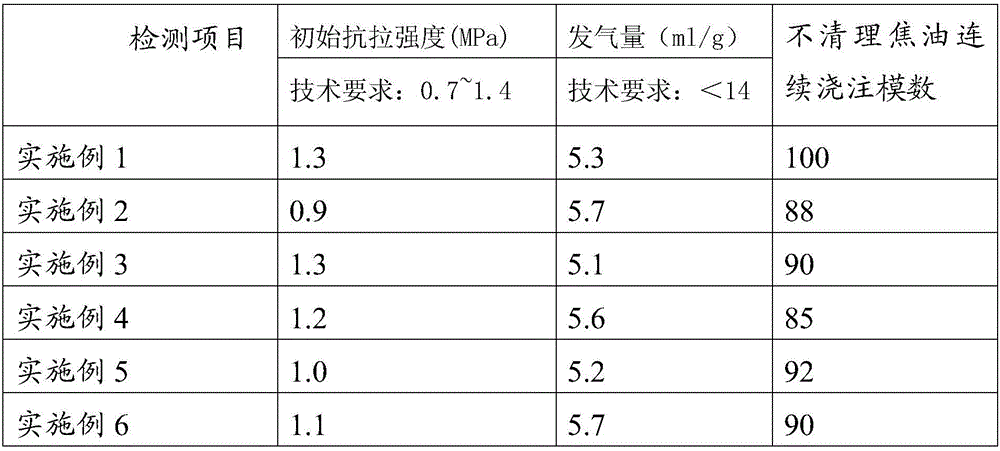

Embodiment 1

[0050] Cold box binder:

[0051] Preparation of component I: In a mixing kettle equipped with a stirrer, add 586 kg of high-ortho benzyl ether phenolic resin with high methylol content, 206 kg of dioctyl adipate, 199 kg of Solvesso 150 aromatic hydrocarbon, A 9 kg of -187 silane, start stirring, and mix for about 2 hours to make the materials evenly mixed. Wherein, the methylol content of the high ortho benzyl ether phenolic resin is 32.99%, and the weight average molecular weight is 1000.

[0052] Preparation of Component II: In a mixing tank equipped with a stirrer, add 800 kg of diphenylmethane-4,4'-diisocyanate, 173 kg of dioctyl phthalate, 18 kg of Solvesso 150 aromatics, A- 9 kg of 187 silanes, started stirring, and mixed for about 2 hours to make the materials evenly mixed.

[0053] The above-mentioned liquid component I and liquid component II are packaged separately in containers to obtain the cold box adhesive of the present invention.

[0054] The cold box binder...

Embodiment 2

[0071] Cold box binder:

[0072] Preparation of component I: In a mixing tank equipped with a stirrer, add 400 kg of high-ortho benzyl ether phenolic resin with high hydroxyl content, 313 kg of dibutyl phthalate, 187 kg of Solvesso 150 aromatic hydrocarbon, A- 100 kg of 187 silane, start stirring, and mix for about 2 hours to make the material mix evenly. Among them, the methylol content of the high ortho benzyl ether phenolic resin is 39.30%, and the weight average molecular weight is 600.

[0073] Preparation of Component II: In a mixing tank equipped with a stirrer, add 800 kg of diphenylmethane-4,4'-diisocyanate, 163 kg of dibutyl phthalate, 10 kg of ethanol, Solvesso 200 aromatics 18 kg, 9 kg of A-174 silane, start stirring, and mix for about 2 hours to make the materials evenly mixed.

[0074] The above-mentioned liquid component I and liquid component II are packaged separately in containers to obtain the cold box adhesive of the present invention.

[0075] The cold ...

Embodiment 3

[0092] Cold box binder:

[0093] Preparation of Component I: In a mixing tank equipped with a stirrer, add 634 kg of high-ortho benzyl ether phenolic resin with high methylol content, 245 kg of dioctyl phthalate, 110 kg of Solvesso 150 aromatics, 11 kg of A-187 silane, start stirring, and mix for about 2 hours to make the materials evenly mixed. Among them, the methylol content of the high ortho benzyl ether phenolic resin is 35.69%, and the weight average molecular weight is 800.

[0094] Preparation of component II: In a mixing tank equipped with a stirrer, add 700 kg of polymethylene polyphenyl polyisocyanate, 111 kg of dioctyl phthalate, 180 kg of Solvesso 100 aromatics, A- 9 kg of 187 silanes, started stirring, and mixed for about 2 hours to make the materials evenly mixed.

[0095] The above-mentioned liquid component I and liquid component II are packaged separately in containers to obtain the cold box adhesive of the present invention.

[0096] The cold box binder o...

PUM

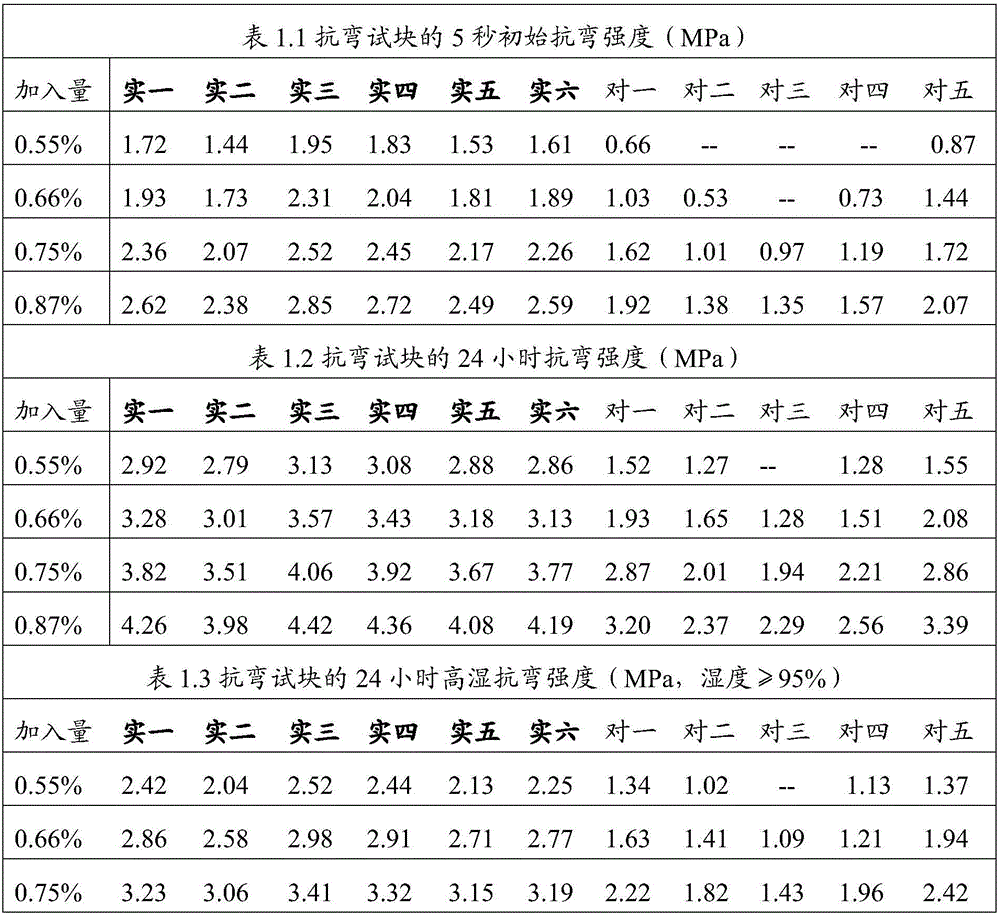

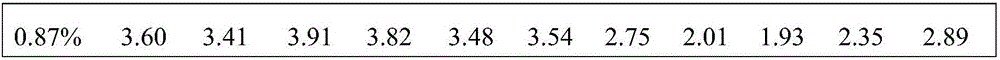

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com