Preparation method of high-capacity silicon-based negative electrode material of lithium-ion battery

A silicon-based negative electrode material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor long-term cycle performance, loss of electrical contact, silicon volume change, etc., to ensure overall stable performance, improve Conductivity, the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a silicon-based anode material for a high-capacity lithium ion battery includes the following steps:

[0024] (1) Add 5g of nano-silicon (particle size: 50nm) to ethanol solvent, ultrasonically disperse for 60min, then add 100g of artificial graphite, mix and stir for 30min, then add 8g of phenolic resin, continue to mix and stir for 60min;

[0025] (2) Spray drying the uniformly mixed slurry to obtain precursor powder;

[0026] (3) The powder obtained in step (2) is heated to 800° C. for 8 hours under the protection of argon gas, cooled to room temperature and then ground to obtain a nano silicon / graphite composite material coated with organic pyrolytic carbon.

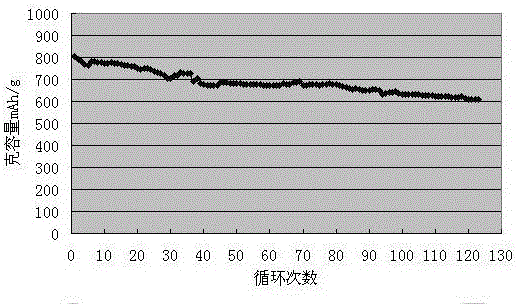

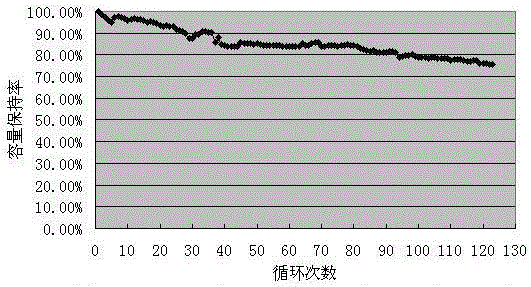

[0027] The mass ratio of the prepared composite material, PVDF, and conductive carbon black is 85:10:5, coated on copper foil as the negative electrode, lithium metal sheet as the counter electrode, and 1mol / L lithium hexafluorophosphorus as the electrolyte , Assembled into button batteries. At...

Embodiment 2

[0029] A method for preparing a silicon-based anode material for a high-capacity lithium ion battery includes the following steps:

[0030] (1) Add 10g of nano-silicon (particle size: 50nm) to ethanol solvent, ultrasonically disperse for 60min, then add 100g of natural graphite, mix and stir for 45min, then add 10g of phenolic resin, continue to mix and stir for 60min;

[0031] (2) Spray drying the uniformly mixed slurry to obtain precursor powder;

[0032] (3) The powder obtained in step (2) is heated to 900° C. for 10 hours under the protection of argon gas, cooled to room temperature and then ground to obtain a nano silicon / graphite composite material coated with organic pyrolytic carbon.

[0033] The mass ratio of the prepared composite material, PVDF, and conductive carbon black is 85:10:5, coated on copper foil as the negative electrode, lithium metal sheet as the counter electrode, and 1mol / L lithium hexafluorophosphorus as the electrolyte , Assembled into button batteries. At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com