High chrome alloy steel with chromium carbide reinforced layer and preparation method of high chrome alloy steel with chromium carbide reinforced layer

A technology of chromium carbide and reinforcement layer, which is applied in metal processing equipment, coatings, manufacturing tools, etc., can solve the problems of uncontrollable size and distribution mode, easy falling off of chromium carbide particles, etc., and achieves easy implementation, simple preparation method, combined firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

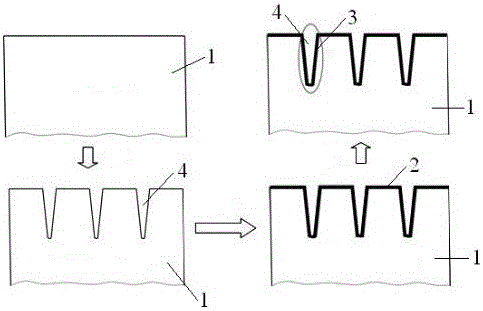

[0030] The preparation method of the above-mentioned high chromium alloy steel with chromium carbide reinforcement layer specifically comprises the following steps:

[0031] Step 1: cleaning the substrate surface with acetone to obtain a surface-treated substrate;

[0032] Step 2: use a laser drilling machine to carry out laser drilling on the surface-treated substrate obtained in step 1 under vacuum conditions or under the protection of an inert gas, and then pickle. The acid solution used for pickling is 300ml / L volume concentration Any one of hydrochloric acid, 60ml / L phosphoric acid, 120ml / L hydrogen peroxide, 300ml / L hydrofluoric acid or 200ml / L sulfuric acid, then rinse with water until neutral, and finally use ethanol or acetone for ultrasonic cleaning to obtain Washed substrate with depressed tubular body;

[0033] Step 3: Place the cleaned substrate with a depressed tubular body obtained in step 2 in a vacuum carburizing furnace for carburizing at a certain temperatu...

Embodiment 1

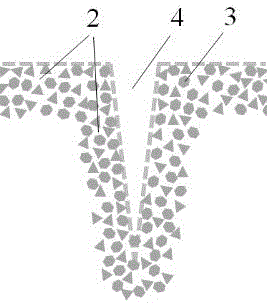

[0047] Preparation of micron-sized tubular chromium carbide reinforced 2Cr12 matrix composites

[0048] Step 1: Smelting 2Cr12 alloy steel, especially controlling the carbon content to 0.2%, cleaning the surface of the 2Cr12 alloy steel with acetone to obtain a surface-treated 2Cr12 alloy steel substrate;

[0049] Step 2: Use a laser drilling machine to perform laser drilling on the surface-treated 2Cr12 alloy steel substrate obtained in step 1 under vacuum conditions, with a hole diameter of 30 μm, a hole depth of 20 μm, and a hole spacing of 1000 μm; then pickling, pickling The acid solution used for washing is hydrochloric acid with a volume concentration of 300ml / L, then washed with water to neutrality, and finally ultrasonically cleaned with ethanol to obtain a 2Cr12 alloy steel substrate with a depressed tubular body after cleaning;

[0050] Step 3: Place the cleaned 2Cr12 alloy steel matrix with a depressed tubular body obtained in step 2 in a vacuum carburizing furnace...

Embodiment 2

[0054] Preparation of micron-sized tubular chromium carbide reinforced 5Cr12MoV matrix composites

[0055] Step 1: Smelting 5Cr12MoV alloy steel, especially controlling the carbon content to 0.5%, cleaning the surface of 5Cr12MoV alloy steel with acetone to obtain a surface-treated 5Cr12MoV alloy steel matrix;

[0056] Step 2: Use a laser drilling machine to perform laser drilling on the surface-treated 5Cr12MoV alloy steel substrate obtained in step 1 under the protection of inert gas argon, with a hole diameter of 20 μm, a hole depth of 18 μm, and a hole spacing of 25 μm; The acid solution used for washing and pickling is hydrofluoric acid with a volume concentration of 300ml / L, then rinsed with water to neutrality, and finally uses acetone to perform ultrasonic cleaning to obtain the cleaned 5Cr12MoV alloy steel substrate with a depressed tubular body;

[0057] Step 3: Place the cleaned 5Cr12MoV alloy steel matrix with a depressed tubular body obtained in step 2 in a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com