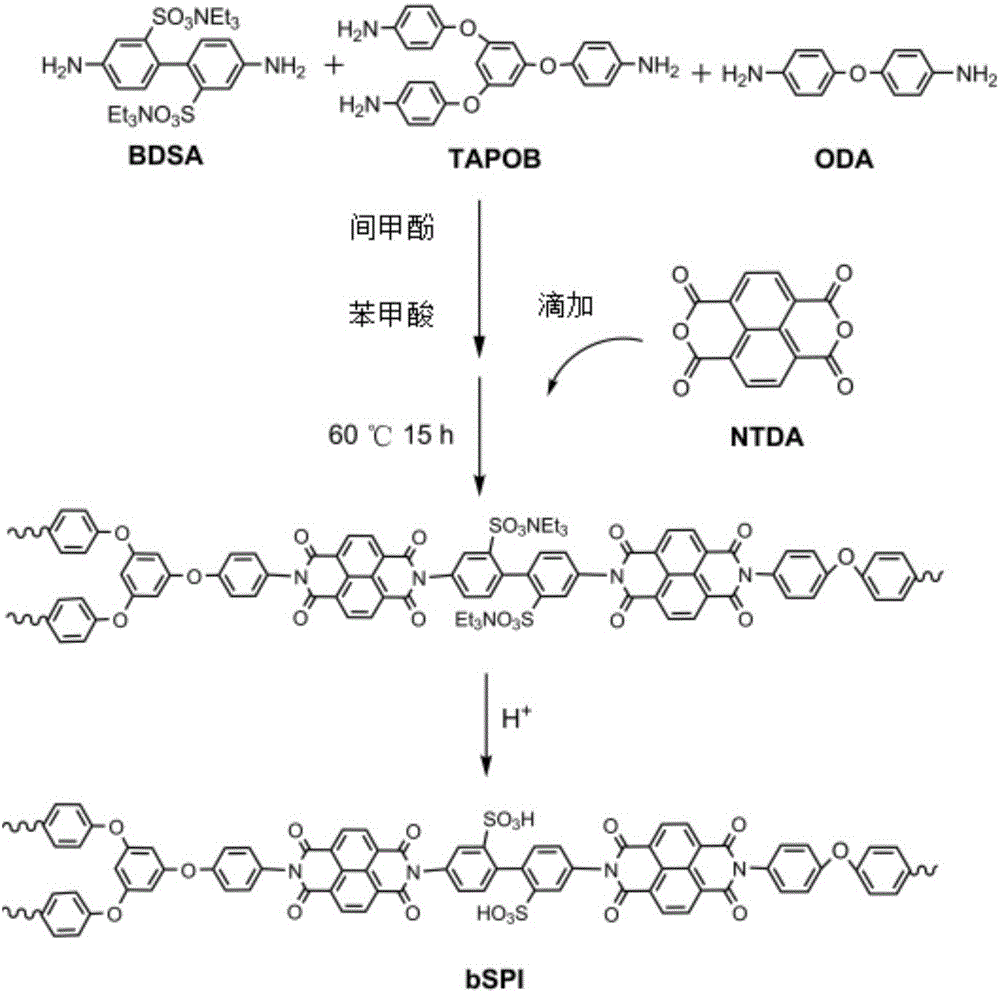

Method for preparing composite proton-conducting film from branched and sulfonated polyimide/two-dimensional layered material

A technology of sulfonated polyimide and proton conductive membrane, which is applied to fuel cell components, electrolyte holding devices, etc., can solve the problems of weak oxidation resistance and low vanadium resistance performance, and achieve low cost and strong resistance Oxidation property, effect of improving proton conductivity and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a branched sulfonated polyimide / two-dimensional layered material composite proton conductive membrane, the steps of which are:

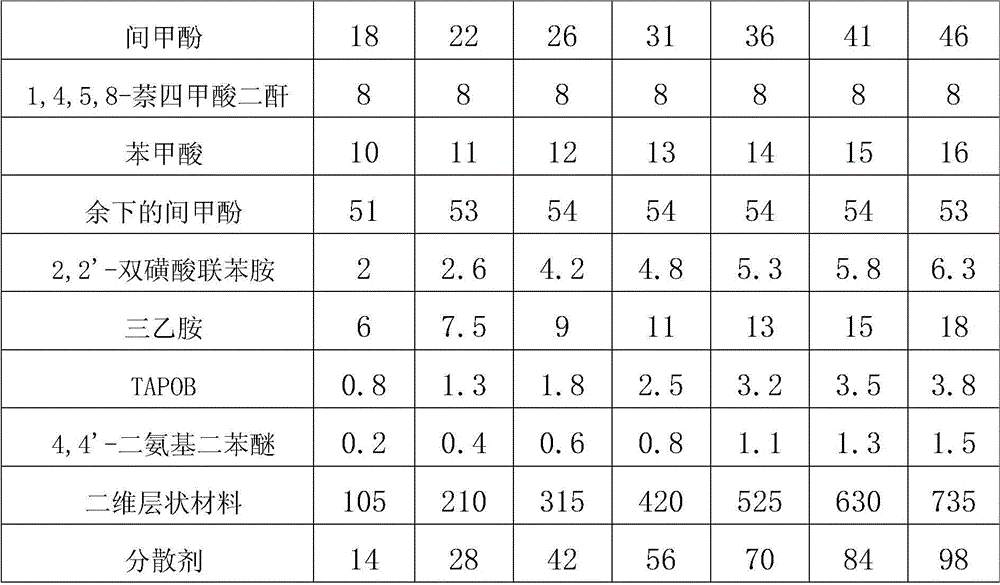

[0032] in N 2 Under protection, add 8.0mmol NTDA, 20mL m-cresol, and 9.8mmol benzoic acid into a 250mL three-neck flask, and stir continuously at room temperature until NTDA and benzoic acid are completely dissolved; dissolve 2.0mmol BDSA in a 50mL m- Add 5.0mmol triethylamine dropwise to cresol, wait until BDSA is completely dissolved, then add 1.0mmol ODA and 3.3mmol TAPOB into the beaker to dissolve completely, and place it in a constant pressure dropping funnel and slowly drop it into a three-necked flask. And the temperature was raised to 50°C for 15 hours to obtain a branched SPI film solution; take 750 mg of layered material and disperse it in 100 mL of NMP, ultrasonicate in a water bath for 2 hours, and the ultrasonic power was 200 W, and after centrifugal sedimentation at 1500 r / ppm for 90 minutes, take the upp...

Embodiment 2

[0037] A preparation method of a branched sulfonated polyimide / two-dimensional layered material composite proton conductive membrane, the steps of which are:

[0038] in N 2 Under protection, add 8.0mmol NTDA, 30mL m-cresol, and 9.8mmol benzoic acid into a 250mL three-neck flask, and stir continuously at room temperature until NTDA and benzoic acid are completely dissolved; Add 5.0mmol triethylamine dropwise to cresol, wait until BDSA is completely dissolved, then add 1.0mmol ODA and 2.67mmol TAPOB into the beaker to dissolve completely, and place it in a constant pressure dropping funnel and slowly drop it into a three-necked flask. And the temperature was raised to 50°C for 20 hours to obtain a branched SPI film solution; take 750 mg of layered material and disperse it in 100 mL of NMP, ultrasonicate in a water bath for 2 hours, and the ultrasonic power was 200 W, and after centrifugal sedimentation at 1500 r / ppm for 90 minutes, take the upper Clear solution, and slowly add...

Embodiment 3

[0043] A preparation method of a branched sulfonated polyimide / two-dimensional layered material composite proton conductive membrane, the steps of which are:

[0044] in N 2 Under protection, add 8.0mmol NTDA, 30mL m-cresol, and 14.7mmol benzoic acid into a 250mL three-neck flask, and stir continuously at room temperature until NTDA and benzoic acid are completely dissolved; dissolve 4.0mmol BDSA in a 70mL m- Add 5.0mmol triethylamine dropwise to cresol, wait until BDSA is completely dissolved, then add 2.0mmol ODA and 1.33mmol TAPOB into the beaker to dissolve completely, and place it in a constant pressure dropping funnel and slowly drop it into a three-necked flask. And raise the temperature to 50°C for 20 hours to obtain a branched SPI membrane solution; take 375 mg of layered material and disperse it in 50 mL of NMP, ultrasonicate in a water bath for 2 hours, and the ultrasonic power is 200 W, and then centrifugally settle at 1500 r / ppm for 90 minutes to take the upper C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com