Medium-high-temperature through type metal solar collector tube

A medium-high temperature, straight-through technology, used in the field of solar thermal utilization, can solve the problems of high temperature resistance and oxidation resistance of material corrosion and heat absorption coating, and achieve the effect of high temperature resistance, high absorption rate, and not easy to mechanical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings.

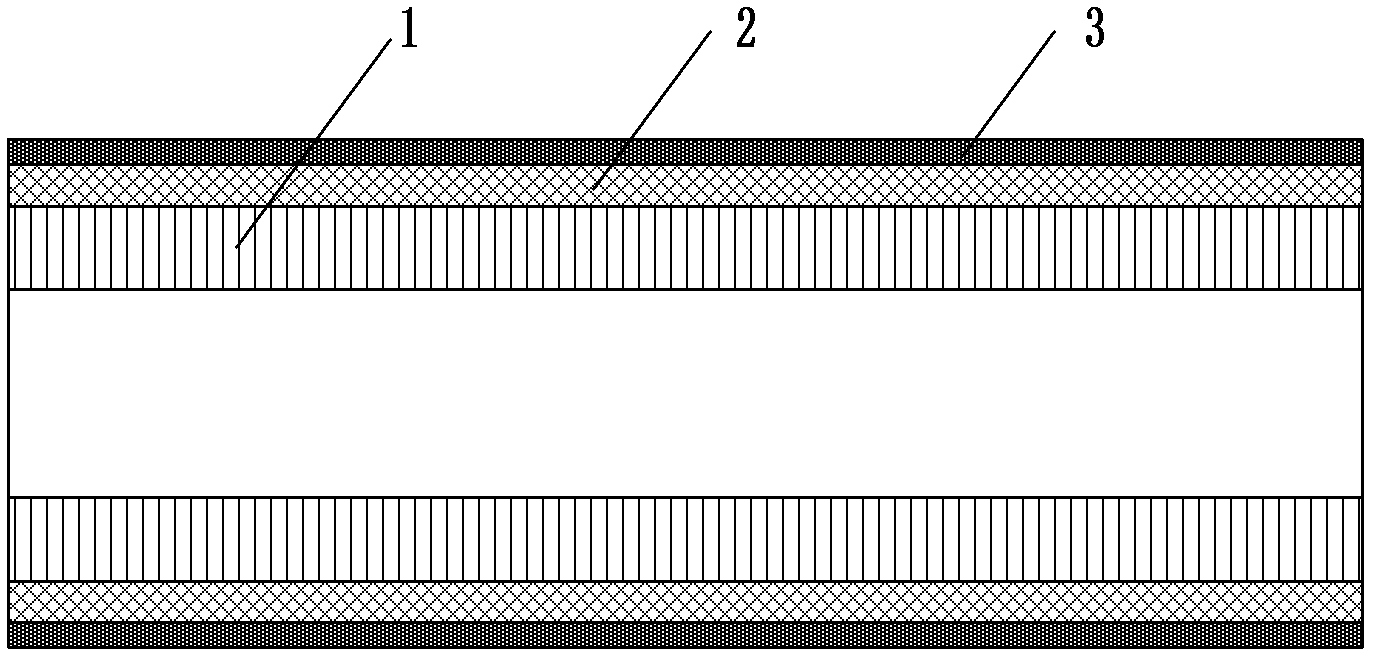

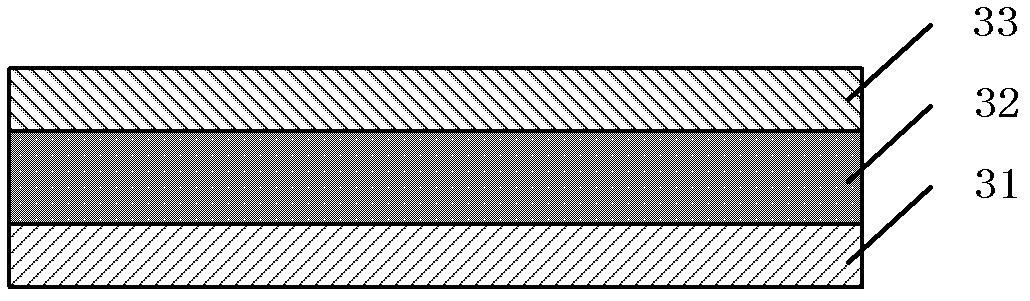

[0017] like figure 1 As shown, the medium and high temperature straight-through solar metal heat collector tube includes a metal base tube 1, and the outer surface of the metal base tube 1 is covered with an anti-corrosion coating 2 and an absorbing coating 3 sequentially from the inside to the outside, wherein the anti-corrosion coating Layer 2 is a high-phosphorus electroless nickel coating, and the thickness of the high-phosphorus electroless nickel coating is 10-20 μm, such as figure 2 As shown, the absorption coating 3 is sequentially composed of a metal infrared reflective sub-coat 31, a high-temperature endothermic sub-coat 32 in a cermet, and an anti-reflection sub-coat 33 from the inside to the outside, and the metal material of the metal infrared reflective sub-coat 31 Using Nb, Cu, Al, Ti, Mg, Rh, Ag or Au, the thickness of the metal infrared reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com