Moving bed biofilm reactor-forward osmosis-reverse osmosis composite wastewater treatment device and nitrogen-containing organic wastewater treatment method

A moving bed biofilm, organic wastewater treatment technology, applied in biological treatment devices, biological water/sewage treatment, multi-stage water treatment, etc., can solve problems such as increased operating costs, increased operating and maintenance costs, and difficulty in effluent quality. , to achieve the effect of low membrane fouling degree and rate, strengthening wastewater treatment effect, and improving wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

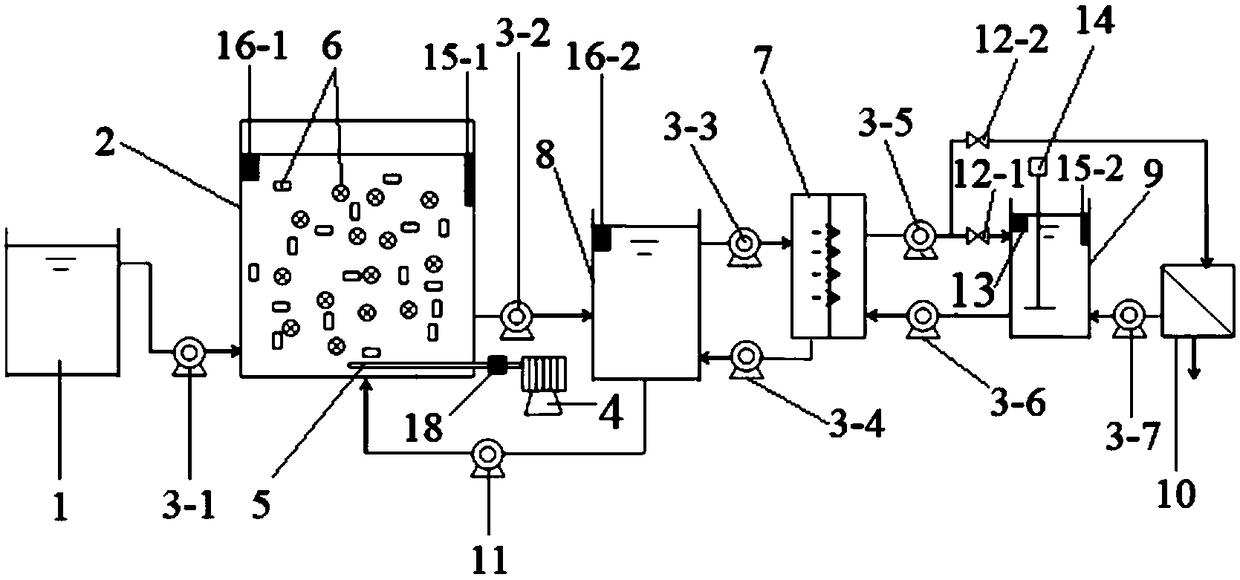

[0034] In this example, the structure of the moving bed biofilm reactor-forward osmosis-reverse osmosis composite wastewater treatment device is as follows figure 1 As shown, it includes a regulating tank 1, a moving bed biofilm reactor 2 equipped with a suspended filler 6, an aeration pipe 5 arranged at the bottom of the moving bed biofilm reactor, an aeration pump 4 connected to the aeration pipe through pipe fittings, Reverse osmosis membrane module 10, forward osmosis membrane module 7, regulating sedimentation tank 8, driving liquid tank 9, sludge return pump 11 and control valve.

[0035] The aeration pipe 5 is a perforated pipe, and a gas flow meter 18 is arranged on the pipe fitting connecting the aeration pipe 5 and the aeration pump 4; Mud inlet, the amount of suspended filler 6 in the moving bed biofilm reactor is 60% of the effective volume of the moving bed biofilm reactor, and the water outlet of the moving bed biofilm reactor is provided with a filter screen to ...

Embodiment 2

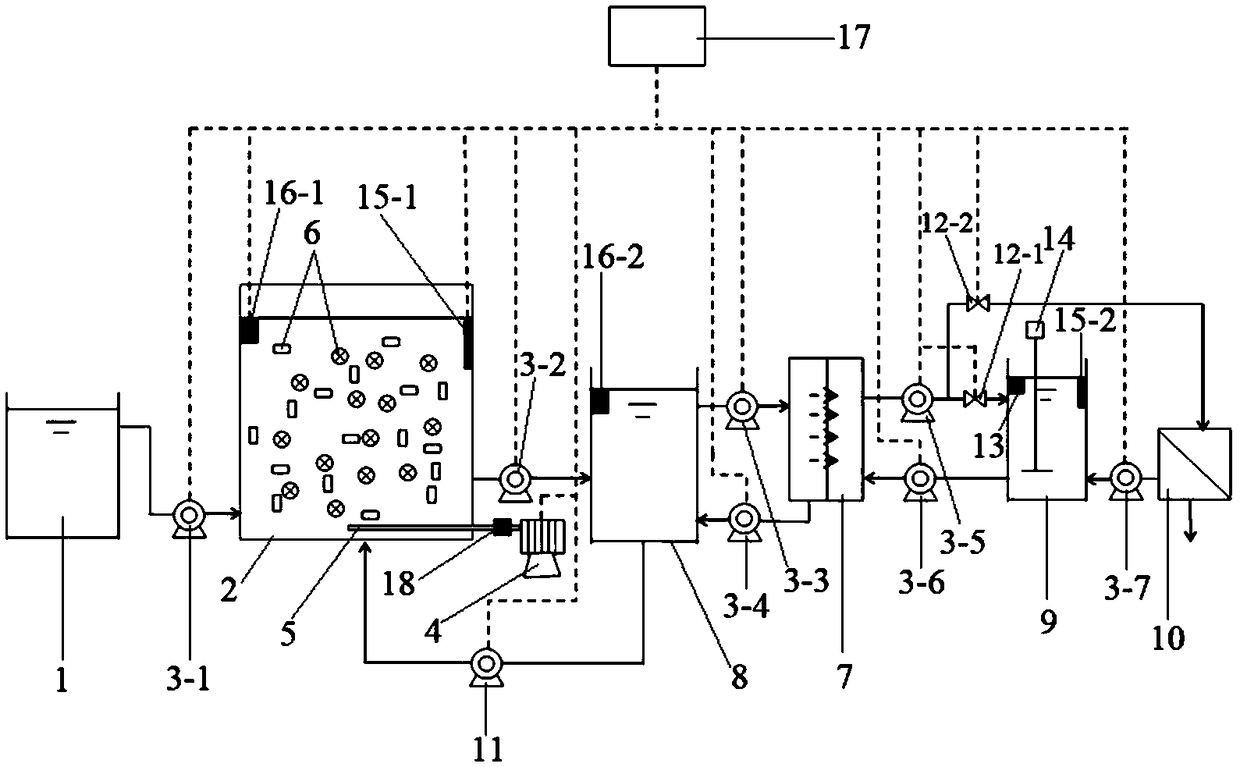

[0038] In this example, the structure of the moving bed biofilm reactor-forward osmosis-reverse osmosis composite wastewater treatment device is as follows figure 2 As shown, it includes a regulating tank 1, a moving bed biofilm reactor 2 equipped with a suspended filler 6, an aeration pipe 5 arranged at the bottom of the moving bed biofilm reactor, an aeration pump 4 connected to the aeration pipe through pipe fittings, Reverse osmosis membrane module 10 , forward osmosis membrane module 7 , regulating sedimentation tank 8 , drive liquid tank 9 , sludge return pump 11 , control valve and computer control system 17 .

[0039] The aeration pipe 5 is a perforated pipe, and a gas flow meter 18 is arranged on the pipe fitting connecting the aeration pipe 5 and the aeration pump 4; Mud inlet, the amount of suspended filler 6 in the moving bed biofilm reactor is 40% of the effective volume of the moving bed biofilm reactor, and the water outlet of the moving bed biofilm reactor is ...

Embodiment 3

[0042] In this example, a method for treating nitrogen-containing organic wastewater using the moving bed biofilm reactor-forward osmosis-reverse osmosis composite wastewater treatment device described in Example 1 is provided. The water quality of the nitrogen-containing organic wastewater is: chemical oxygen demand The dosage is 800-950mg / L, the concentration of ammonia nitrogen is 65-80mg / L, and the pH value is 6.5-7.0. The steps are as follows:

[0043] ① Pass the waste water into the regulating pool 1 under stirring to evenly adjust the water quality in the pond;

[0044] 2. Carry out biofilm cultivation to the suspended filler in the moving bed biofilm reactor 2, the cultivation method of biofilm is: add waste water and activated sludge in the moving bed biofilm reactor, the COD concentration of described waste water is 800mg / L , ammonia nitrogen concentration is 90mg / L, and the add-on of described waste water is 90% of effective volume of moving bed biofilm reactor, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com