Cerium-zirconium composite oxide, preparation method of cerium-zirconium composite oxide and use of catalyst

A composite oxide, cerium zirconium technology, applied in the field of its preparation, cerium zirconium composite oxide, can solve the limitations affecting the catalytic performance, stability and consistency of catalytic application effect of cerium zirconium composite oxide, cerium zirconium composite oxide Insufficient high temperature stability and other problems, to achieve the effect of good catalytic application performance and effect, high temperature stability improvement, good temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

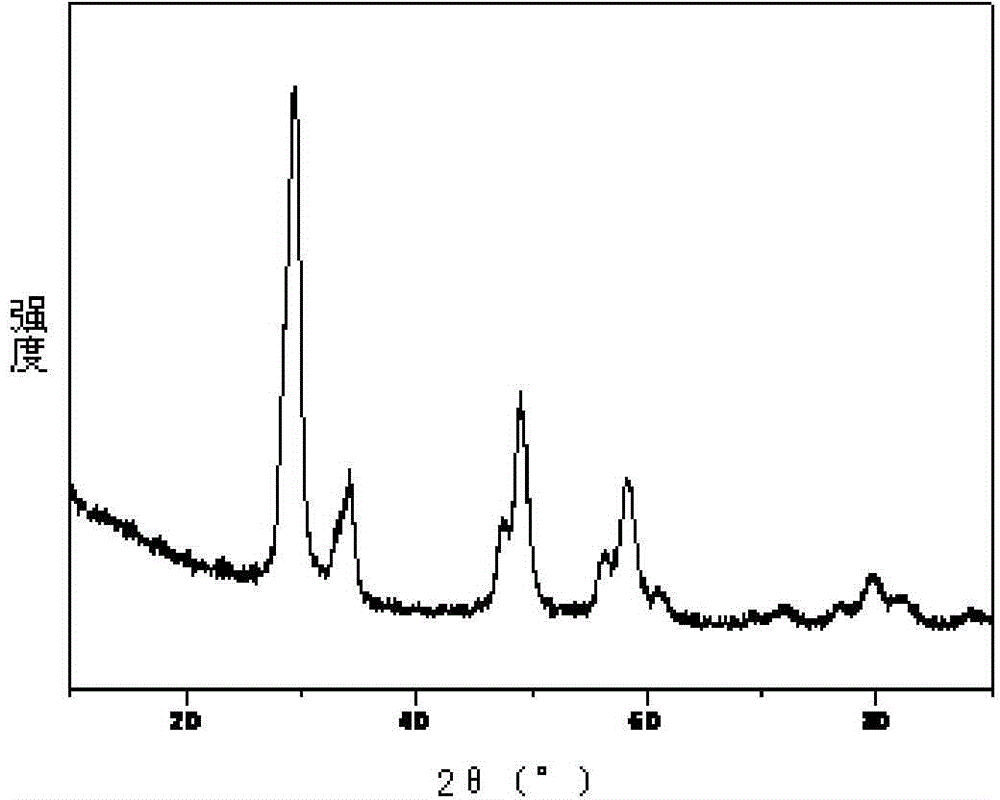

Image

Examples

preparation example Construction

[0034] According to another aspect of the present invention, there is provided a method for preparing a cerium-zirconium composite oxide, the preparation method comprising the following steps: Step S1, the components of the cerium-zirconium solid solution phase in the cerium-zirconium composite oxide provided according to the present invention Proportionally configure the feed solution A containing tetravalent cerium ions, zirconium ions and doped metal ions, and configure the trivalent cerium ion solution according to the proportion of the cerium oxide phase in the cerium-zirconium composite oxide, and add the trivalent cerium ion solution to the trivalent cerium ion solution Add the complex to obtain the feed liquid B, wherein the doped metal ion is M in the cerium-zirconium composite oxide, and the complex contains complex ions of cerium ions; step S2, adding the feed liquid A, the feed liquid B and the precipitant at the same time Mixing and reacting in the reactor, adjusti...

Embodiment 1

[0048] The preparation method of the cerium-zirconium composite oxide provided in this embodiment comprises the following steps:

[0049] First, the molar ratio of Ce / Zr / Nd is 35:61:4 for batching to obtain a mixed solution A (volume of 3 L) of tetravalent cerium nitrate, neodymium nitrate and zirconium oxynitrate cerium-zirconium solid solution with a concentration of 1.5M; Then configuration concentration is the trivalent cerium nitrate solution of 1.5M as cerium oxide phase raw material solution and adds and accounts for trivalent cerium ion molar weight 10% ethylenediaminetetraacetic acid to obtain feed liquid B (volume is 160ml); Next, by and Liquid A, liquid B and precipitant ammonia water were mixed and precipitated by means of flow feeding, the pH value of the reaction system was adjusted to 10, the reaction time was 3 hours, and the reaction temperature was 60°C to obtain a cerium-zirconium composite hydroxide precipitation slurry. After the precipitation slurry was a...

Embodiment 2

[0053] At first, be 35:60:5 to carry out batching by the mol ratio of Ce / Zr / La, obtain the cerium ammonium nitrate, lanthanum nitrate and zirconium oxynitrate cerium zirconium solid solution mixed solution A (volume is 3L) that concentration is 1.5M; Configuration concentration is that the cerium chloride solution of 1.5M is as cerium oxide phase raw material solution and adds and accounts for trivalent cerium ion molar weight 3% citric acid to obtain feed liquid B (volume is 100ml); Liquid A, liquid B and the precipitating agent sodium hydroxide are mixed for precipitation reaction, the pH value of the reaction system is adjusted to 9, the reaction time is 3 hours, and the reaction temperature is 60°C to obtain the cerium-zirconium composite hydroxide precipitation slurry, and the precipitation slurry Put it into a high-pressure reactor, and age it hydrothermally at 200°C for 3 hours to obtain a cerium-zirconium composite hydroxide precipitation slurry, and filter, wash, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com