Preparation method and application of supported catalyst for methane dry reforming

A supported catalyst, methane dry reforming technology, applied in the direction of chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of CO and H2 ratio deviation, deactivation, etc., to achieve high Stability, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

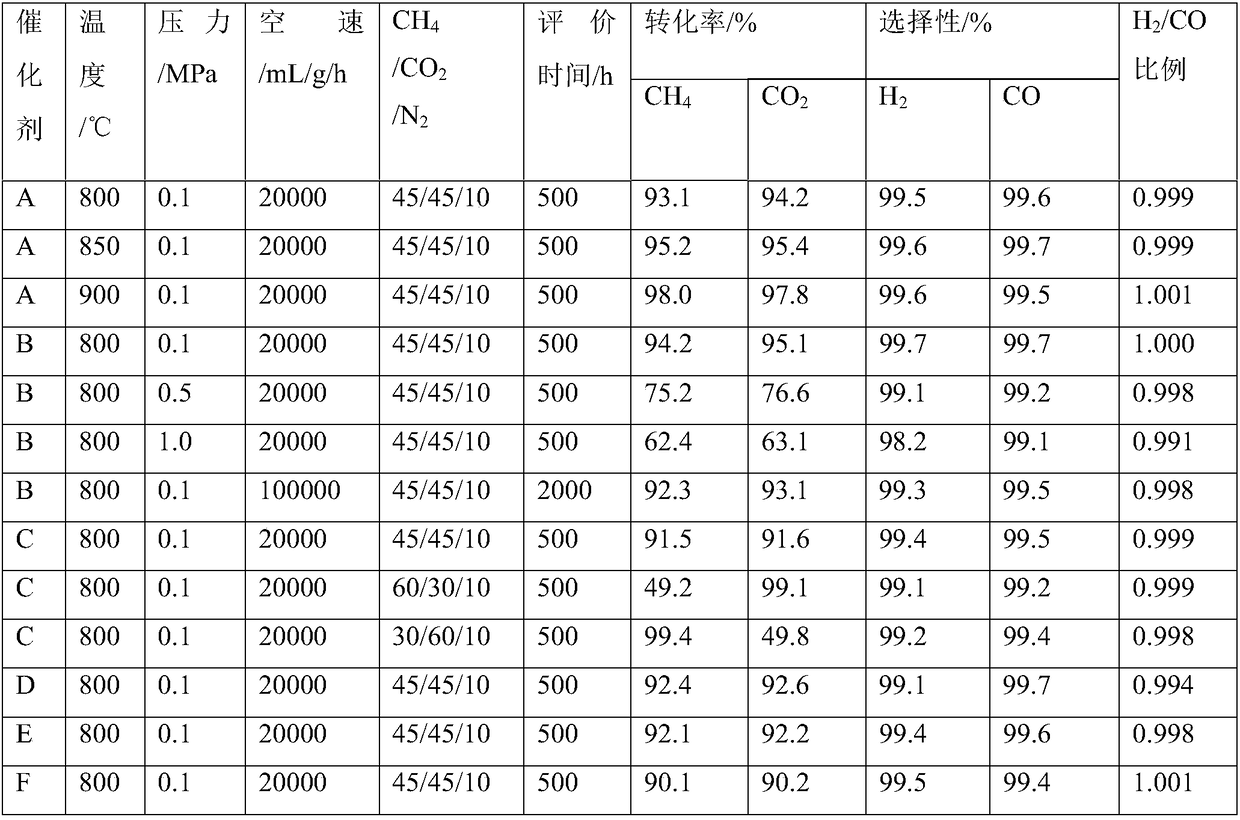

[0033] Weigh 5.82g of Ni(NO 3 ) 2 ·6H 2 O, 3.02g of glycine and 1.65g of NH 4 NO 3 It was dissolved in a certain amount of aqueous solution and stirred continuously at room temperature for 12 hours. Subsequently, 13.5 g of silicon dioxide was quickly added in an equal-volume preparation method and stirred evenly. It was dried under vacuum at 80°C, then dried in an oven at 120°C for 5 hours, and then calcined in a muffle furnace at 500°C for 5 hours to obtain catalyst powder. Finally, the 40-60 mesh particles were pressed, crushed and screened for activity evaluation, and the prepared catalyst was marked as catalyst A, wherein the mass fraction of NiO was 10.2%. The transmission electron microscope image (JEOL, JEM 2100) of the catalyst structure can be seen figure 1 , it can be seen that the particle size of the catalyst prepared by the combustion method is small, and the average particle size is only 5 nanometers.

Embodiment 2

[0035] Weigh 5.98g of Ni(NO 3 ) 2 ·6H 2 O, the ruthenium nitrate of 0.11g, the glycine of 3.14g and the NH of 1.78g 4 NO 3 It was dissolved in a certain amount of aqueous solution and stirred continuously at room temperature for 12 hours. Subsequently, 13.9 g of aluminum oxide was quickly added in an equal-volume preparation method, and stirred evenly. It was dried under vacuum at 80°C, then dried in an oven at 120°C for 5 hours, and then calcined in a muffle furnace at 500°C for 5 hours to obtain catalyst powder. Finally, the 40-60 mesh particles were pressed, crushed and screened for activity evaluation. The prepared catalyst was marked as catalyst B, in which the mass fraction of NiO was 10.6%, and the mass fraction of Ru was 0.2%.

Embodiment 3

[0037] Weigh 7.23g of palladium nitrate, 5.14g of urea and 2.12g of NH 4 NO 3 It was dissolved in a certain amount of aqueous solution and stirred continuously at room temperature for 12 hours. Subsequently, 14.2 g of aluminum oxide was quickly added in an equal-volume preparation method and stirred evenly. It was dried under vacuum at 100°C, then dried in an oven at 180°C for 12 hours, and then calcined in a muffle furnace at 700°C for 5 hours to obtain catalyst powder. Finally, the 40-60 mesh particles were pressed, crushed and screened for activity evaluation. The prepared catalyst was marked as Catalyst C, and the mass fraction of PdO was 9.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com