Hyperbranched polyester-modified polyurethane medical interventional catheter and manufacturing method thereof

A technology of hyperbranched polyester and interventional catheters, which is applied in the field of medical devices to achieve good lubricity, high lubricity and wear resistance, and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

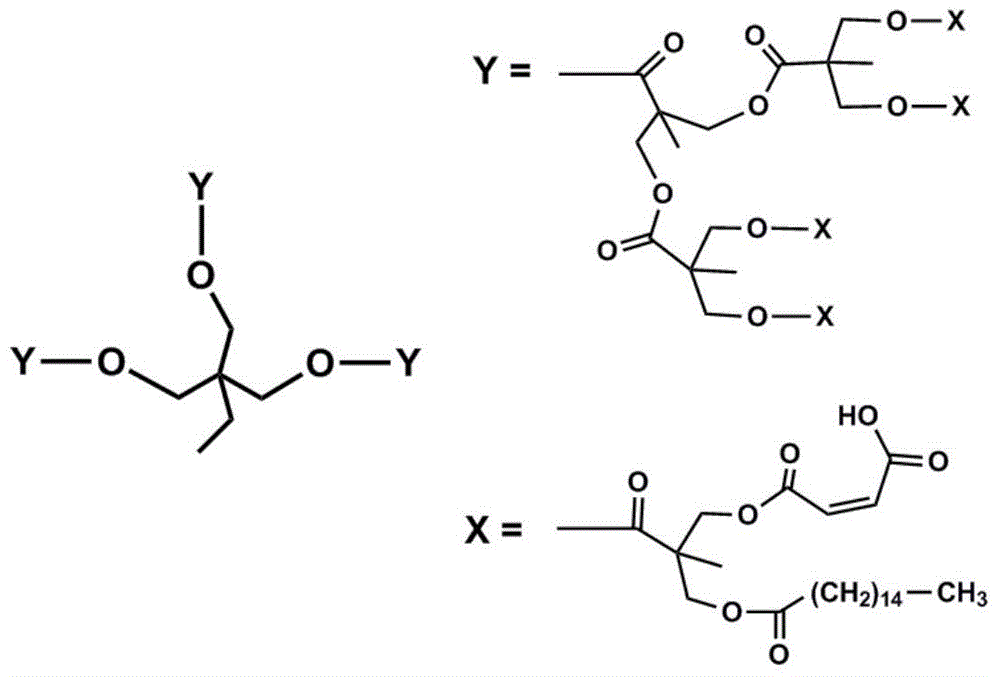

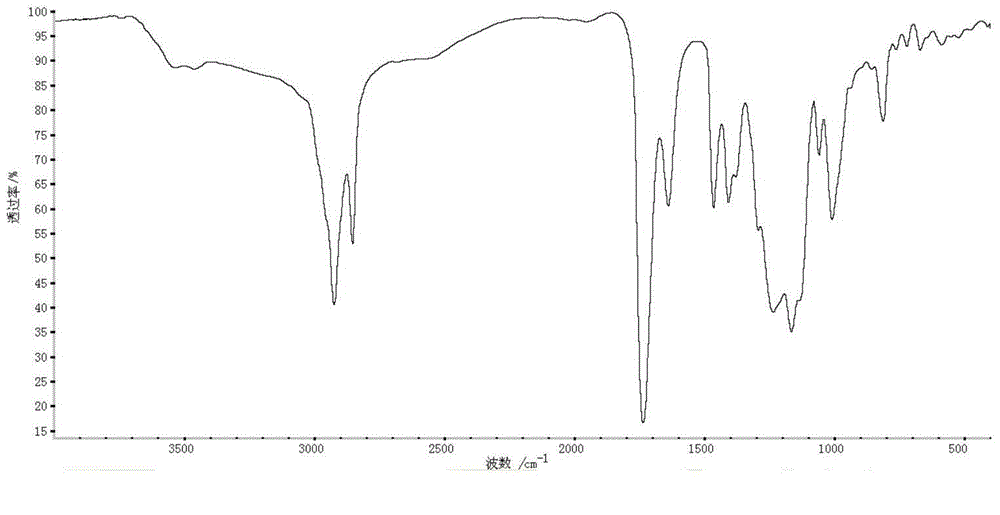

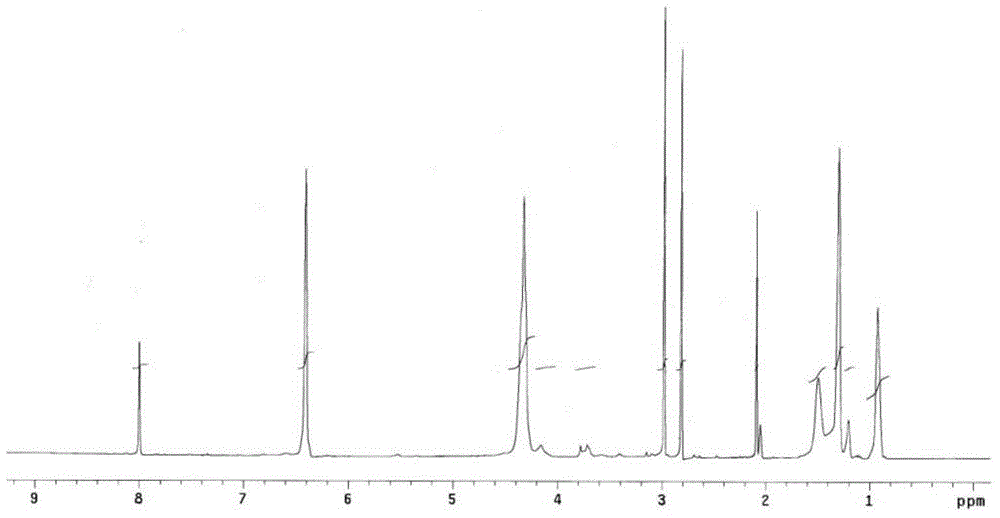

[0043] Preparation of hyperbranched polyesters containing carboxyl and palmitate groups:

[0044]Add 10g of trimethylolpropane into the reactor, raise the temperature to 140°C, add dimethylolpropionic acid in three steps, first add 30g of dimethylolpropionic acid, mix well and then add 0.21g of p-toluenesulfonate Acid, stir under reduced pressure until no bubbles are produced, add 60g of dimethylolpropionic acid, mix well, stir under reduced pressure until no bubbles are produced, add 120g of dimethylolpropionic acid, mix well and then stir under reduced pressure React until no bubbles are generated, add 229.3g of palmitic acid, mix well, then stir under reduced pressure to react until no bubbles are generated, wherein the vacuum degree during the reaction under reduced pressure and stirred is 0.1kPa, cool to 80°C, add 3553g of N, N-dimethylformamide, after the solid intermediate product is dissolved, add the maleic anhydride of 438.8g, be down to room temperature after 12 hou...

Embodiment 2

[0047] Preparation of hydrophilic coating primer (B-Coating):

[0048] Add water-based polyurethane, trimethylolpropane-tris[3-(2-methylaziridinyl)]propionate, deionized water, wetting agent and silane coupling agent to the container, stir at room temperature In 30 minutes, the primer was obtained, and the quality of trimethylolpropane-tris[3-(2-methylaziridinyl)]propionate in the primer was 5% of the water-based polyurethane quality, and the amount of deionized water The ratio of the mass to the mass of the water-based polyurethane is 20:1, and the mass of the wetting agent and the silane coupling agent are respectively 0.1% of the mass of the water-based polyurethane.

[0049] Preparation of hydrophilic coating top coat (T-Coating):

[0050] Add water-based polyurethane, polyvinylpyrrolidone, deionized water, wetting agent and silane coupling agent into the container, stir at room temperature for 30 minutes to obtain a top coat, and the quality of polyvinylpyrrolidone in th...

Embodiment 3~12

[0056] Preparation of hyperbranched polyester modified polyurethane medical intervention catheter:

[0057] Mix the hyperbranched polyester with carboxyl group and palmitate group at the end group and thermoplastic polyurethane elastomer in a certain weight ratio, and record the mass ratio of hyperbranched polyester to polyurethane elastomer as F-b, and melt and mix it through a screw extruder After extrusion molding, the polyurethane catheter with carboxyl group in the pipe wall is obtained, and the catheter is treated with hydrophilic coating (Coating). After the primer is applied to the polyurethane catheter, it is cured at 60 ° C for 2 hours, and then the top coating is applied Coating on the polyurethane catheter that has been coated with the primer, curing at 60° C. for 6 hours to obtain a hyperbranched polyester modified polyurethane medical intervention catheter.

[0058] The thermoplastic polyurethane elastomer is the thermoplastic polyurethane (Pellethane2363-65D mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com