Application of polydimethylsiloxane, fluorescent film and preparation method thereof

A technology of polydimethylsiloxane and fluorescence, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of low UV transmittance and low overall spectrum transmittance, and achieve good UV transmittance, Chemical properties are stable and the effect of increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

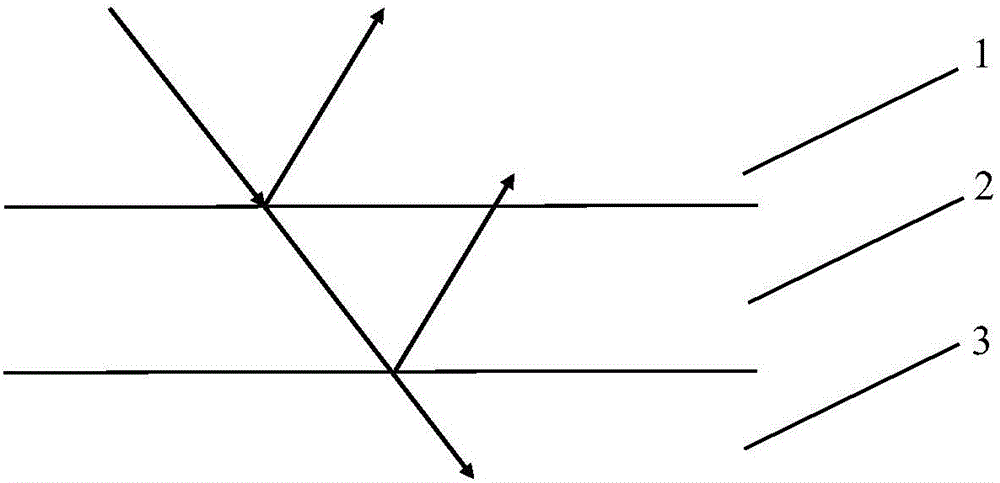

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the above-mentioned fluorescent film, comprising: A) mixing fluorescent dye, polydimethylsiloxane and curing agent to obtain a suspended colloidal solution; B) spin-coating the suspended colloidal solution Form a film to obtain a fluorescent film.

[0034] Wherein, the fluorescent dye, polydimethylsiloxane and curing agent are the same as those described above, and will not be repeated here.

[0035] The fluorescent dye is preferably ground first, and then mixed with polydimethylsiloxane and curing agent to obtain a suspension colloidal solution. The purpose of grinding is to grind some unacceptable large particles. It has been proved by experiments that the number of particles visible to the naked eye on the surface of the powder that has not been ground is twice as large as that of the powder that has been ground.

[0036] In the present invention, in order to make the fluorescent dye better mix with polydim...

Embodiment 1

[0046] 1.1 Preparation of modified fused silica glass substrate: Scrub the quartz glass substrate with absolute ethanol; ultrasonically clean the substrate for 30 minutes with an ultrasonic cleaner; wash with ultrapure water for several times, and blow dry with nitrogen. Oxygen plasma surface treatment equipment was used to modify the surface of the fused silica glass substrate to be hydrophilic.

[0047] 1.2 Preparation of sol: Use a precision electronic balance to take an appropriate amount of mixed solutions of Lumogen and PDMS A and B, and the mass ratio of Lumogen and PDMS is 0.05:1.

[0048] A, B solution (the A solution is silicone rubber (silicone elastomer) i.e. polydimethylsiloxane, the B solution is a silicone rubber curing agent (silicone elastomer curing agent) i.e. curing agent) after mixing and stirring to remove air bubbles, Then use a balance scale to take 87mg of Lumogen and put it into 1.65g of PDMS A, B mixed solution, add a magnet to the beaker of the mixe...

Embodiment 2

[0051] 2.1 Use an AG245 precision weighing balance to weigh 227 mg of lumogen powder, and use an agate mortar to fully grind the lumogen powder before weighing. Use an appropriate amount of solvent to magnetically stir with lumogen for about 30 minutes in a sealed container.

[0052] 2.2 Clean the fused silica glass substrate, scrub it with a cotton ball dipped in ethanol, ultrasonicate for 20 minutes, blow dry with nitrogen, put it into GiGabatch for surface modification, and change the surface of the fused silica glass substrate into a hydrophilic structure.

[0053] 2.3 Prepare a total of 1.65g of colloids A and B of PDMS and mix and stir at a mass ratio of 10:1. After the stirring is completed, remove air bubbles in a vacuum.

[0054] 2.4 Mix the lumogen suspension with PDMS to obtain a mixture with a concentration of 10%, seal and stir evenly for 4 to 5 hours, then open and heat with magnetic stirring, and stir for 5 minutes. Do not use vacuum to remove air bubbles, beca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com