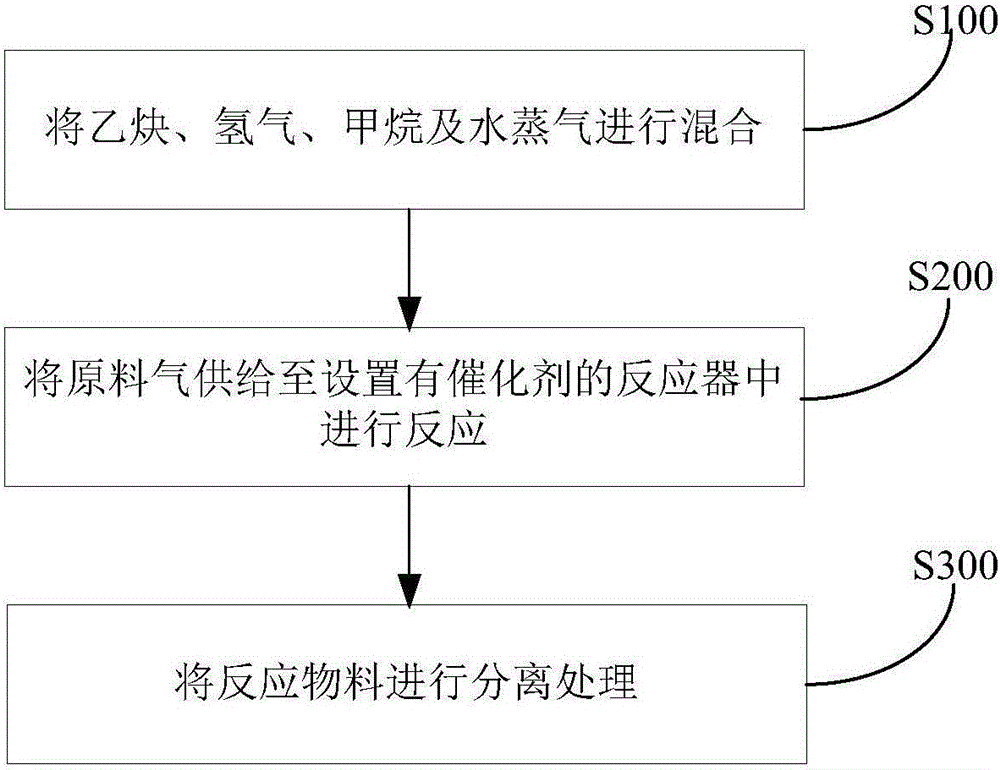

Method for preparing benzene and co-producing ethylene from acetylene

An acetylene and ethylene technology, applied in the field of acetylene to prepare benzene and co-production of ethylene, can solve the problems of complex catalyst preparation, difficult heat transfer, harsh process conditions, etc., achieve adjustable product selectivity, avoid complex preparation, and overcome difficulties in heat transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Mix acetylene, hydrogen, methane, water vapor and carbon dioxide to obtain raw material gas, wherein the molar ratio of acetylene, hydrogen and methane in the raw material gas is 1:3:2, the water vapor content in the raw material gas is 100-2000ppm, and the carbon dioxide is 1000ppm; the average pressure of the raw material gas is 0.75MPa, the temperature of the raw material gas is 35°C, and then the raw material gas is supplied to the tubular fixed bed filled with catalyst, and the part of the tubular fixed bed that is in contact with the raw material gas is made of enamel material. Among them, the catalyst is prepared by the impregnation method, the particle size is 20-40 mesh, the active components are palladium, copper and nickel, the loading capacity is 0.05wt% of the carrier, the catalyst carrier is a glass fiber mesh, and the reactor operating space velocity is 3000h -1 , the reaction temperature is 450°C to carry out the reaction to obtain a reaction material co...

Embodiment 2

[0050] Mix acetylene, hydrogen, methane, water vapor and carbon dioxide to obtain a raw material gas, wherein the molar ratio of acetylene to hydrogen and methane in the raw material gas is 1:1:4, the water vapor content in the raw material gas is 1000ppm, and the carbon dioxide is 500ppm. The average pressure of the raw material gas is 0.55MPa, the temperature of the raw material gas is 80°C, and then the raw material gas is supplied to the moving bed filled with catalyst, and the part in contact with the raw material gas in the moving bed is made of ceramic material, wherein the catalyst is prepared by impregnation method The particle size is 5-8mm, the active component metals are palladium, copper, iron and nickel, the loading capacity is 0.04wt% of the carrier, and the catalyst carrier is α-Al 2 o 3 , the reactor operating space velocity is 2000h -1 , the reaction temperature is 650°C, and the reaction is carried out to obtain a reaction material containing benzene, ethyl...

Embodiment 3

[0052] Mix acetylene, hydrogen, methane, water vapor, carbon dioxide, carbon monoxide, and ethane to obtain raw material gas, wherein the molar ratio of acetylene, hydrogen and methane in the raw material gas is 1:3.5:1, and the water vapor content in the raw material gas is 2000ppm , carbon dioxide is 1000ppm, carbon monoxide is 500ppm, ethane is 200ppm, temperature; feed gas average pressure is 0.45MPa, feed gas temperature is 30°C. Then the raw material gas is supplied to the fluidized bed filled with catalyst, and the part in contact with the raw material gas in the fluidized bed is made of graphite material, wherein, the catalyst is prepared by impregnation method, the particle size is 20-40 mesh, and the active component The metal is palladium, copper and nickel, the load is 0.05wt% of the carrier, the catalyst carrier is glass beads, and the reactor operating space velocity is 3000h -1 , the reaction temperature is 750°C, and the reaction is carried out to obtain a reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com