A kind of ch4-co2 catalytic reforming reaction device and its technology

A CH4-CO2, catalytic reforming technology, applied in the field of catalytic synthesis, can solve the problems of carbon deposition and other problems, achieve high reaction conversion rate, overcome catalyst deactivation, and eliminate carbon deposition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

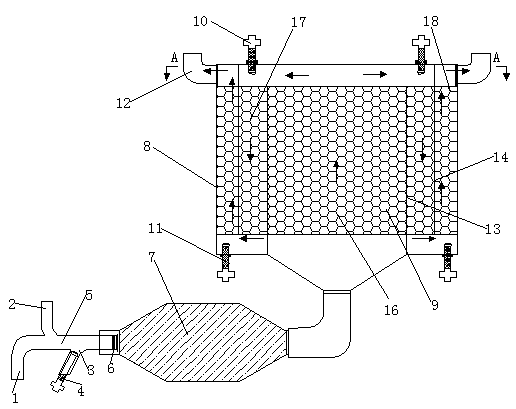

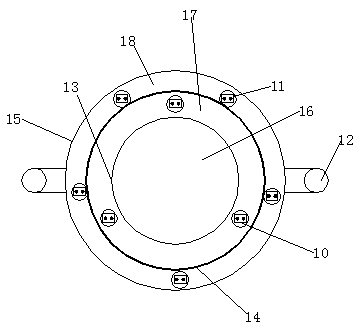

[0031] Example 1: CH 4 -CO 2 Catalytic reforming reaction device and reaction principle

[0032] CH provided by the present invention 4 -CO 2 Catalytic reforming reaction device, such as Figure 1~2Shown, comprise feed pipe, gas mixer, reactor, feed pipe comprises methane feed pipe 1, carbon dioxide feed pipe 2, methane feed pipe 1 and carbon dioxide feed pipe 2 merge into feed main pipe 5, enter The feed main pipe 5 is connected to the gas mixer 7 and the reactor 8 in turn, and the feed main pipe 5 is connected to the first anion generator 4, and the other end of the feed main pipe 5 is connected to the reactor 8 through the gas mixer 7; the reactor 8 It is a multi-cylinder reactor, and the reactor is provided with an inner cylinder 13 and an outer cylinder 14 to divide the reactor into an inlet chamber 16, an inner annular chamber 17, and an outer annular chamber 18; the inner cylinder 13 is fixed on the reactor 8 On the lower bottom plate of the reactor 8, the inner si...

Embodiment 2

[0045] Example 2: CH 4 -CO 2 Catalytic reforming reaction process

[0046] According to above-mentioned reaction technique, one group of concrete embodiment is provided:

[0047] Include the following steps:

[0048] (1) Feed:

[0049] The flow rate of oxygen entering the first negative ion generator is 0.15L / min, the flow rate of methane is 1L / min, and the flow rate of carbon dioxide is 0.7L / min; and the methane and carbon dioxide are preheated to about 500°C; the feed pipes are opened at the same time, and the material ratio Be methane: carbon dioxide: the intake air volume of the first anion generator=1:0.7:0.15;

[0050] (2) Initial reaction and activation:

[0051] The activation and preliminary reaction are completed in the mixer; the preliminary reaction time is about 3~5s;

[0052] (3) Reforming reaction: The temperature in the reactor is controlled at 950°C and the pressure is 2MPa. Under the action of the catalyst, the material passes through the in...

Embodiment 3

[0054] Example 3: CH 4 -CO 2 Catalytic reforming reaction process

[0055] According to above-mentioned reaction technique, one group of concrete embodiment is provided:

[0056] Include the following steps:

[0057] (1) Feed:

[0058] The flow rate of oxygen entering the first negative ion generator is 0.5L / min, the flow rate of methane is 10L / min, and the flow rate of carbon dioxide is 13L / min; and the methane and carbon dioxide are preheated to about 500°C; the material ratio is methane: carbon dioxide: first Intake volume of negative ion generator = 1:1.3:0.05;

[0059] (2) Initial reaction and activation:

[0060] The activation and preliminary reaction are completed in the mixer; the preliminary reaction time is about 3~5s;

[0061] (3) Reforming reaction: The temperature in the reactor is controlled at 950°C and the pressure is 2MPa. Under the action of the catalyst, the material passes through the inlet chamber, the inner annular chamber, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com