Preparation method of low density and high strength foam glass sintering at low temperature

A foam glass and low-temperature sintering technology, applied in the field of multifunctional materials, can solve the problems of high foaming temperature, unsatisfactory porosity and mechanical properties, etc., and achieve the effects of high mechanical strength, simple and feasible process system, and fuel cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

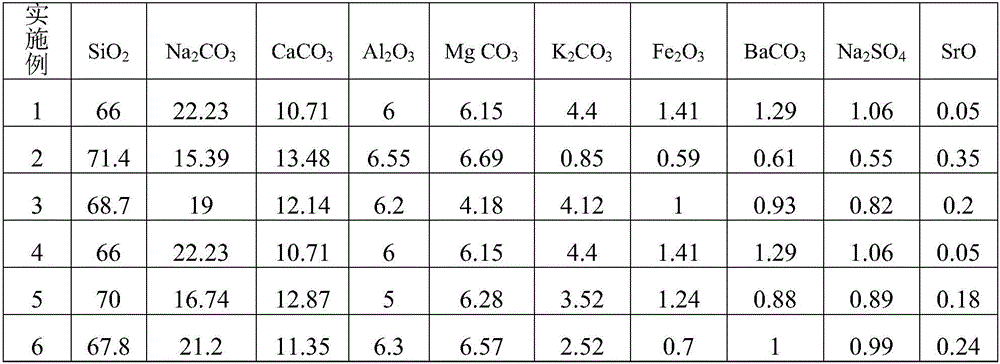

Embodiment 1

[0030] (1) Take 66g of silicon dioxide, 22.23g of sodium carbonate, 10.71g of calcium carbonate, 6g of aluminum oxide, 6.15g of magnesium carbonate, 4.4g of potassium carbonate, 1.41g of iron oxide, 1.29g of barium carbonate, and 1.06g of sodium sulfate with an electronic balance g, strontium oxide 0.05g. Add them together into the ball mill tank for dry grinding; the mass ratio of balls and materials is 2:1, and the mass ratio of large balls: medium balls: small balls is 1:2:1; ensure good sealing, and put them into high-temperature resistance furnace after dry grinding for 5 hours The temperature is raised to 1300°C to start melting, and the basic glass is obtained by water quenching immediately after being out of the furnace. Carry out ball milling with the same method after drying the broken basic glass obtained again, pass 140 mesh sieves after 5 hours and make basic glass powder.

[0031] (2) Take 60 g of basic glass powder and add 3.6 g of lithium carbonate into a ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com