A kind of SIC-Zrb2 gradient coating on the surface of SIC-based composite material and preparation method thereof

A composite material and gradient coating technology, which is applied in the field of oxidation protection of ceramic matrix composite materials, achieves the effects of low cost, simple process, and wide cracking process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] SiC-ZrB on the surface of a SiC-based composite material 2 The preparation method of gradient coating, the steps are:

[0042] (a) Place the raw materials of each layer in different ceramic ball mill jars, and mill them for 10-120 minutes;

[0043] (b) respectively adding a ceramic precursor and a solvent into the ceramic ball milling pot in step (a) for ball milling, the ball milling time is 3 to 120 min, and after the ball milling is completed, the slurry is obtained in the ceramic ball milling pot;

[0044] The mass fraction of the ceramic precursor is 10%-35%, the mass fraction of the solvent is 15%-50%, and the mass fraction of the raw material is 45%. -60%;

[0045] (c) polishing, cleaning and drying the SiC-based composite material;

[0046] (d) the slurry in the step (b) is brushed on the surface of the composite material in sequence, and dried after brushing;

[0047] (e) placing the SiC-based composite material coated with the slurry on the surface obtaine...

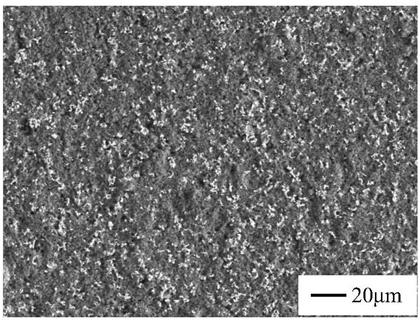

Embodiment 1

[0060] By SiC and ZrB 2 The molar ratio is 10:1; 4:1; 1:1; 0.4:1, respectively weigh the corresponding powder. Among them, the purity of SiC is 99%, the particle size is 500nm, ZrB 2 The purity is 99%, the particle size is 200nm, placed in a ceramic ball mill jar, milled for 20 minutes, the powder is taken out and classified, numbered A, B, C, D, and set aside. Polycarbosilane and divinylbenzene (DVB) were formulated as a precursor solution at a mass ratio of 1:0.6. Take 12wt% precursor solution, 38wt% THF and 50wt% powders of the above 4 kinds of proportions and mix them in a ball mill jar respectively, mill for 3 minutes, and take out the mixed slurry, numbered as a , b, c, d. Grinding, cleaning and drying the C / SiC composite material. Brush the slurry of a, b, c, and d on the surface of the composite material in turn, and let it dry after brushing. Place brushed coating on N 2 Medium curing, the curing temperature is 220°C, and the curing time is 2h. The cured coatin...

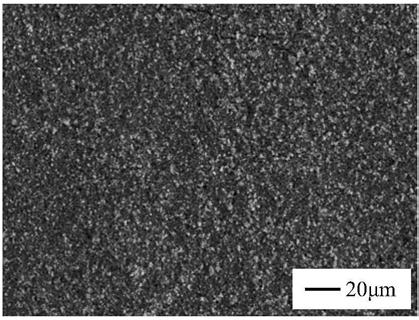

Embodiment 2

[0066] By SiC and ZrB 2 The molar ratio is 10:1; 4:1; 1:1; 0.4:1, respectively weigh the corresponding powder. Among them, the purity of SiC is 99%, the particle size is 500nm, ZrB 2 The purity is 99%, the particle size is 200nm, placed in a ceramic ball mill jar, milled for 20 minutes, the powder is taken out and classified, numbered A, B, C, D, and set aside. Take 20wt% of polysilazane, 36wt% of THF and 44wt% of the powders of the above 4 kinds of proportions and mix them in a ball mill jar respectively, mill for 3 minutes, take out the mixed slurry, and the number is a, b, c, d. Grinding, cleaning and drying the C / SiC composite material. Brush slurry a and b in sequence on the surface of the composite material, and let it dry after brushing. then place it in N 2 Medium curing, the curing temperature is 220°C, and the curing time is 2h. Brush the slurry c and d on the surface of the cured coating in sequence, dry it, and cure it at 220°C for 2 hours. The cured coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com