Hyaluronic acid/polylactic acid-glycollic acid copolymer composite cartilage repair material with radial orientation pore structure and preparation method thereof

A glycolic acid copolymer and hyaluronic acid technology, used in medical science, prosthesis, tissue regeneration, etc., can solve the problems of cell infiltration and migration obstacles, restrict the exchange of substances, etc., to promote material exchange and biological signal communication, Improve secretion and deposition, achieve activation and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Completely dissolve 1 g of hyaluronic acid in 100 mL of deionized water, add 2 mL of methacrylic anhydride under stirring condition, keep the pH value of the solution at 8, and the temperature at 0 o Under the condition of C, the reaction was carried out for 12 hours, and the reactant was repeatedly precipitated by ethanol and dried to obtain methacrylic acid-modified hyaluronic acid;

[0028] 2) Dissolve the modified hyaluronic acid in deionized water, prepare a hyaluronic acid aqueous solution with a mass concentration of 5%, put the solution in a polyethylene mold, and set it at 37 o C for 1 hour at constant temperature;

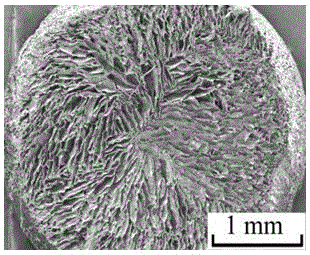

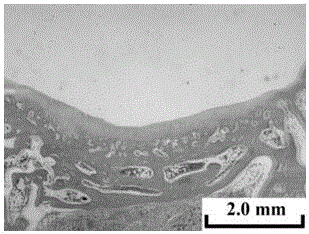

[0029] 3) Put the polyethylene mold at -20 o C In the pre-cooled copper mold, the heat is transferred along the radial direction, and the solvent crystallization is also along the radial direction. After the solvent is completely crystallized, it is freeze-dried, and the dried scaffold is cross-linked under ultraviolet light for 2 hours to obt...

Embodiment 2

[0033] 1) Completely dissolve 2 g of hyaluronic acid in 100 mL of deionized water, add 4 mL of methacrylic anhydride under stirring conditions, and keep the pH value of the solution at 9 and the temperature at 0 o Under the condition of C, the reaction continued for 16 hours, and the reactant was repeatedly precipitated with ethanol and dried to obtain methacrylic acid-modified hyaluronic acid;

[0034] 2) Dissolve the modified hyaluronic acid in deionized water to prepare a hyaluronic acid aqueous solution with a mass concentration of 8%, put the solution in a polyethylene mold, and set it at 37 o C under constant temperature for 2 hours;

[0035] 3) Put the polyethylene mold at -15 oC In the pre-cooled copper mold, the heat is transferred along the radial direction, and the solvent crystallization is also along the radial direction. After the solvent is completely crystallized, it is freeze-dried, and the dried scaffold is cross-linked under ultraviolet light for 4 hours t...

Embodiment 3

[0039] 1) Completely dissolve 3 g of hyaluronic acid in 100 mL of deionized water, add 6 mL of methacrylic anhydride under stirring conditions, and keep the pH value of the solution at 8 and the temperature at 0 o Under the condition of C, the reaction continued for 24 hours, and the reactants were repeatedly precipitated with ethanol and dried to obtain methacrylic acid-modified hyaluronic acid;

[0040] 2) Dissolve the modified hyaluronic acid in deionized water to prepare a hyaluronic acid aqueous solution with a mass concentration of 8%, put the solution in a polyethylene mold, and set it at 37 o C under constant temperature for 1.5 hours;

[0041] 3) Put the polyethylene mold at -20 o C In the pre-cooled copper mold, the heat is transferred along the radial direction, and the solvent crystallization is also along the radial direction. After the solvent is completely crystallized, it is freeze-dried, and the dried scaffold is cross-linked under ultraviolet light for 4 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com