Aluminum alloy conductor wind energy cable for fixation and laying

An aluminum alloy conductor and aluminum alloy technology, applied in conductors, insulated cables, power cables, etc., can solve the problem that copper is not resistant to seawater acid and alkali corrosion, and achieve the effects of low construction cost, enhanced flexibility, and resolution of resource shortages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, illustrate the concrete content of the present invention in detail:

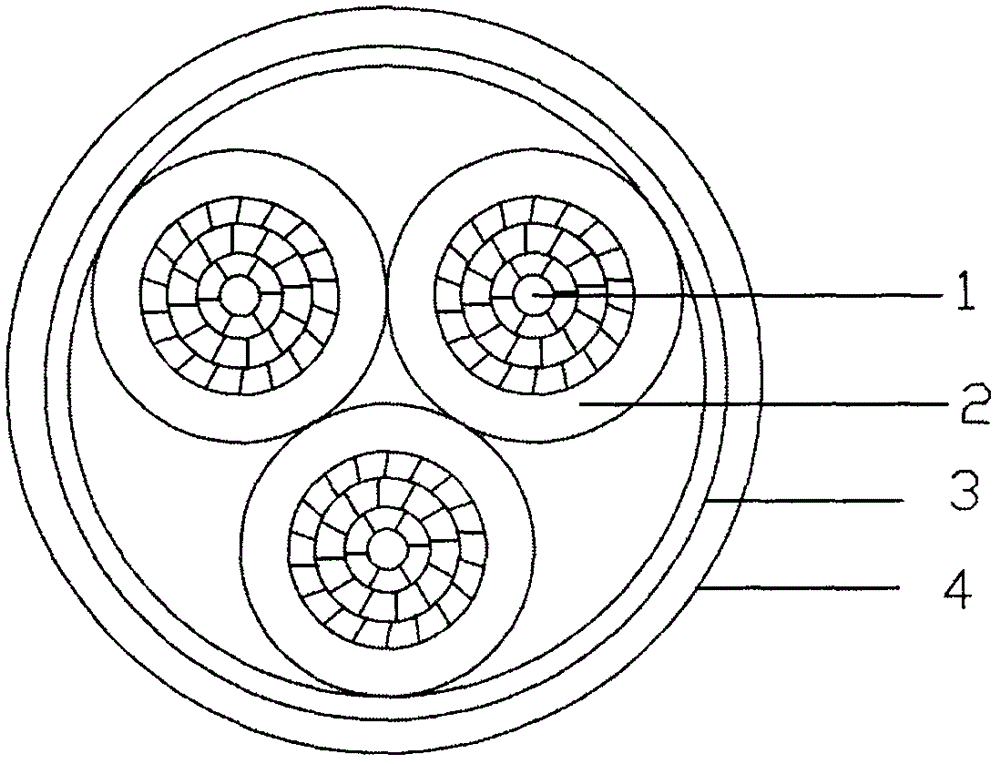

[0024] Such as figure 1 Extrude a silane cross-linked insulating layer 2 on the conductor 1 shown, then twist three extruded silane cross-linked insulating wires to form a cable core, use aluminum alloy tape self-locking armor 3 outside the cable core, and finally The outer sheath 4 is extruded from the armor layer 3 .

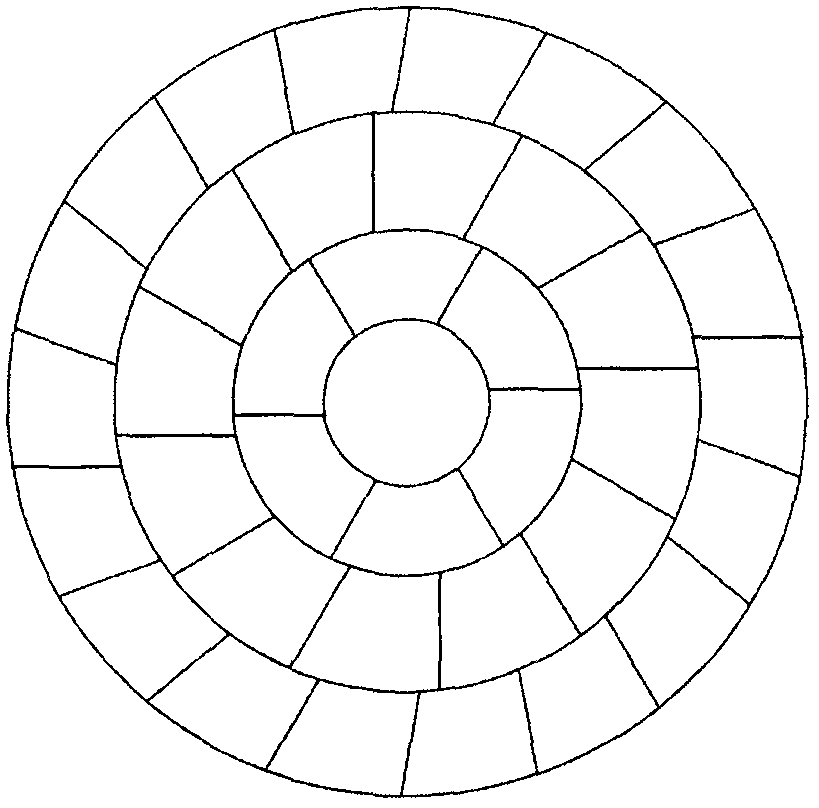

[0025] Adding iron, silicon, copper, magnesium, zinc, boron and other trace elements to the aluminum material improves the tensile strength, elongation and thermal expansion of the conductor, and reduces the temperature and extrusion of the conductor. "Creep" phenomenon;

[0026] The aluminum alloy conductors are produced by using the original type aluminum alloy conductors for inter-embedded stranding technology, which improves the conductivity of the aluminum alloy conductors, making them higher than pure aluminum and second only to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com