A kind of waxy crude oil pouring point and viscosity reducing composite agent

A crude oil pour point depressant and compounding agent technology, which is applied in the field of pour point depressant and waxy crude oil depressant, can solve the problems of sensitivity to temperature rise of added crude oil, deterioration of temperature rise, and increased wax deposition in pipelines, etc., to achieve Long-acting aging, stable electrical insulation, and lowering of freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Preparation of surface-modified polyorganosilsesquioxane particles. 0.02 g of polymer stabilizer polyvinylpyrrolidone and 0.2 g of surfactant sodium dodecyl diphenyl ether disulfonate were completely dissolved in 25 ml of deionized water. The temperature of the system was controlled at 15-20° C., and 5 mg of 28 wt % ammonia water was added to adjust the pH of the system, and the stirring was continued. After one hour, 9.30 g of methyltrimethoxysilane was gradually added into the system, and reacted overnight at room temperature. The surfactant and other impurities are removed by centrifugation and sedimentation to obtain the polyorganosilsesquioxane particles (with a particle diameter of about 2 μm) of the present invention.

[0014] The above-prepared polyorganosilsesquioxane particles and polyoctearyl acrylate pour point depressant are directly melt-blended at 130°C at a mass ratio of 1:4 to obtain polyoctearyl acrylate / polyorganosilicon sesquioxane Oxy-alkane compo...

Embodiment 2

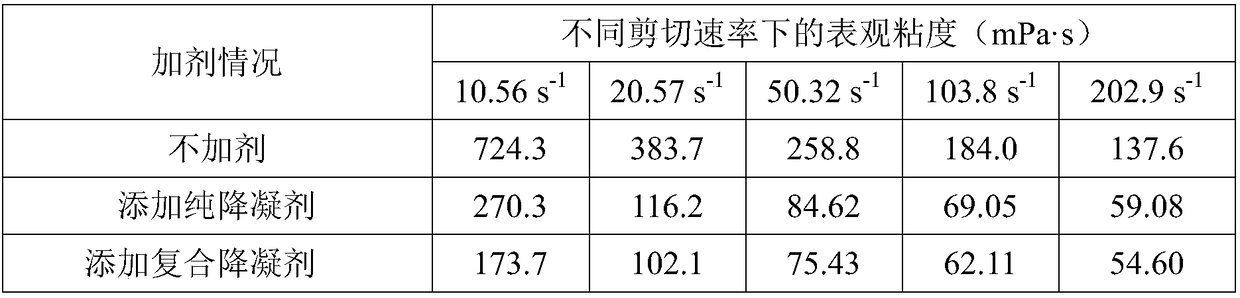

[0022] Example 2: The polyorganosilsesquioxane particles prepared in Example 1 and ethylene-vinyl acetate copolymer (EVA28150) were directly melt-blended at 130°C at a mass ratio of 1:9 to obtain polyvinyl acetate Vinyl ester / polyorganosilsesquioxane composite product (hereinafter referred to as composite pour point depressant). Add polyethylene vinyl acetate pour point depressant at 50 mg / kg and composite pour point depressant at 50 mg / kg to a certain waxy crude oil in China, heat each oil sample at 60°C, and use The point standard measurement method was used to determine the freezing point, and the results are shown in Table 4; the apparent viscosity at 10° C. (non-Newtonian fluid temperature) was measured using a rotational rheometer, and the results are shown in Table 5.

[0023] Table 4

[0024] Dosing situation

No additives

Add pure pour point depressant

Add compound pour point depressant

Freezing point / ℃

22

8

6

[0025] table ...

Embodiment 3

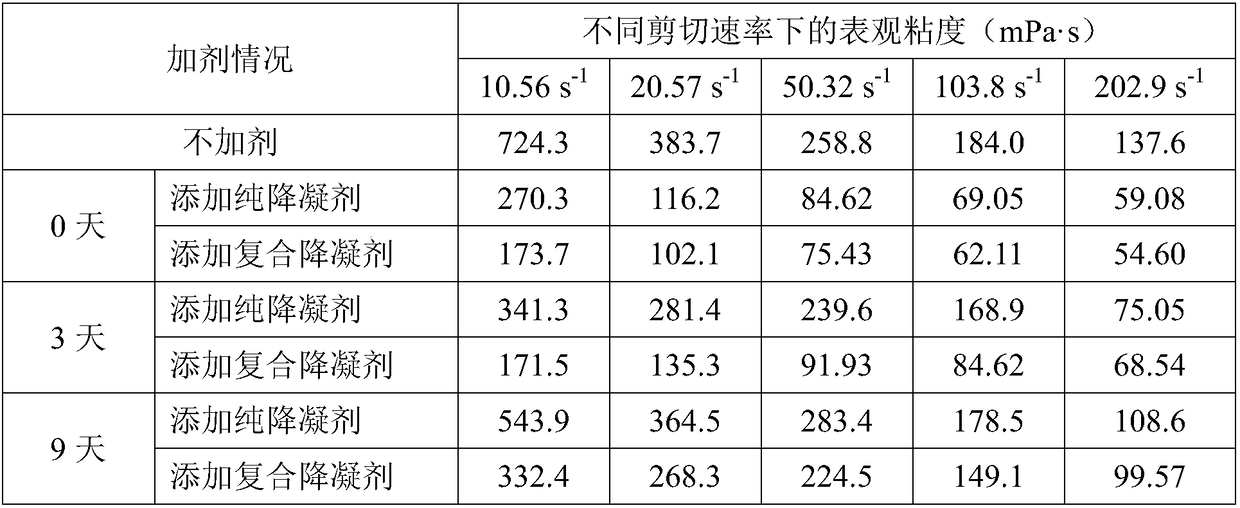

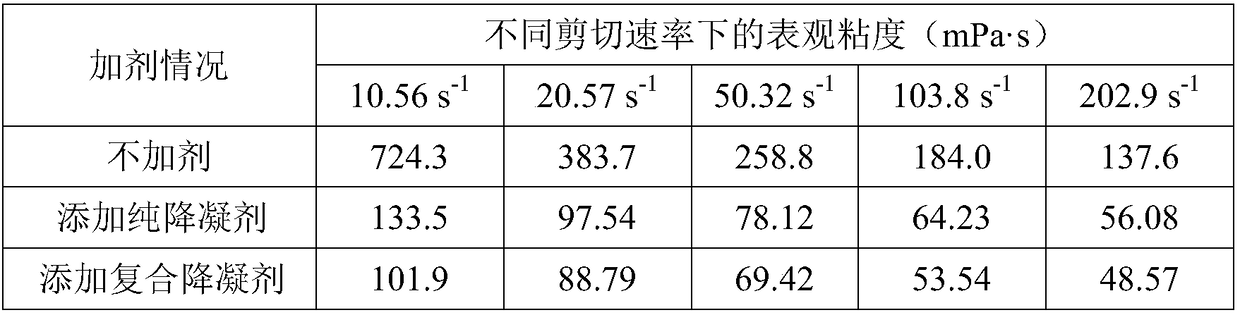

[0027] Example 3: The polyorganosilsesquioxane particles prepared in Example 1 were mixed with ethylene-vinyl acetate copolymer (EVA28150) in a mass ratio of 1:4 in 10 wt% toluene for 6 hours to obtain polyethylene - Vinyl acetate / polyorganosilsesquioxane composite product (hereinafter referred to as composite pour point depressant). At the same time, a polyethylene-vinyl acetate / 10wt% toluene system was prepared for parallel experiments. Add polyethylene vinyl acetate pour point depressant at 50 mg / kg and compound pour point depressant at 50 mg / kg to a certain waxy crude oil in China, heat each oil sample at 60°C, and use a rotary The rheometer measures its apparent viscosity at 10°C (non-Newtonian fluid temperature), and the results are shown in Table 6. At 5°C, the structural yield value at low temperature was measured by continuously increasing the shear stress with a rotational rheometer, and the results are shown in Table 7.

[0028] Table 6

[0029]

[0030] Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com