Poly (3,4-ethylenedioxythiophene) nanowire thin film and synthetic method and application thereof

An ethylenedioxythiophene and nanowire technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of limited large-scale application, poor plasticity, and monotonous color, and achieve excellent electrochromic performance and product purity. High efficiency and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

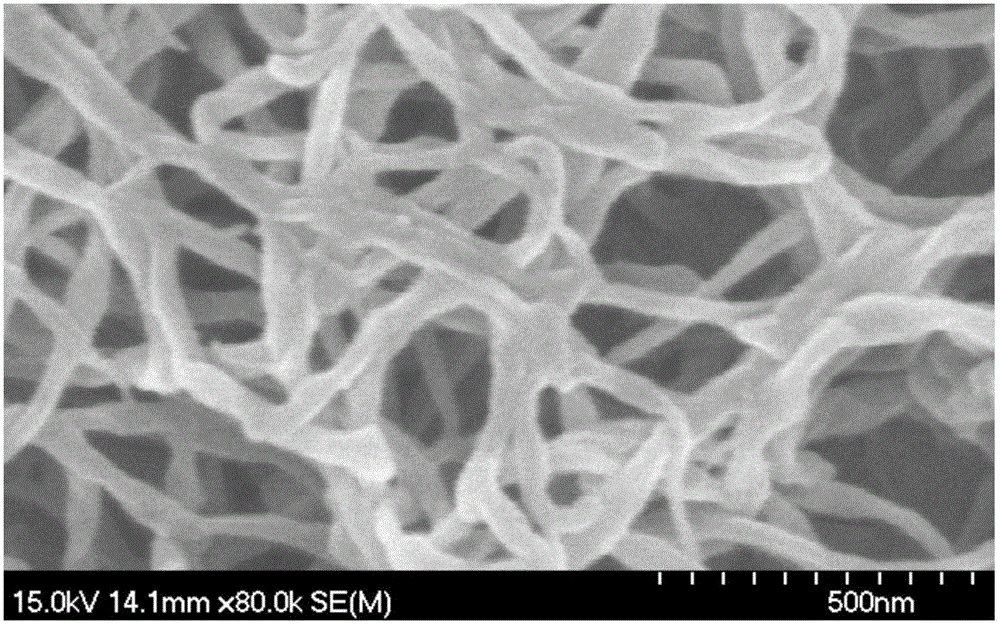

[0038] (1) Preparation of polymer (PEDOT) nanowire film

[0039] Mix EDOT monomer (0.07109g, 0.5mmol), 1-butyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide salt (0.0419g, 0.01mol) and dichloromethane (100mL) to prepare 100 mL of a mixed solution with a monomer concentration of 0.005 mol / L and a supporting electrolyte concentration of 0.1 mol / L was used as the electrolyte. The electrolytic cell adopts a three-electrode system, with ITO conductive glass as the working electrode (sonicated in toluene, acetone, and ethanol for 15 minutes), and polished platinum wire as the auxiliary electrode (the length of the platinum wire is 4 cm), and the reference electrode uses a double liquid Junction-type silver / silver chloride electrode (Ag / AgCl, 3mol / L potassium chloride aqueous solution is used as the first junction, and the electrolyte prepared above is used as the second junction). At room temperature (25°C), the polymer film was prepared by cyclic voltammetry anodic oxidat...

Embodiment 2

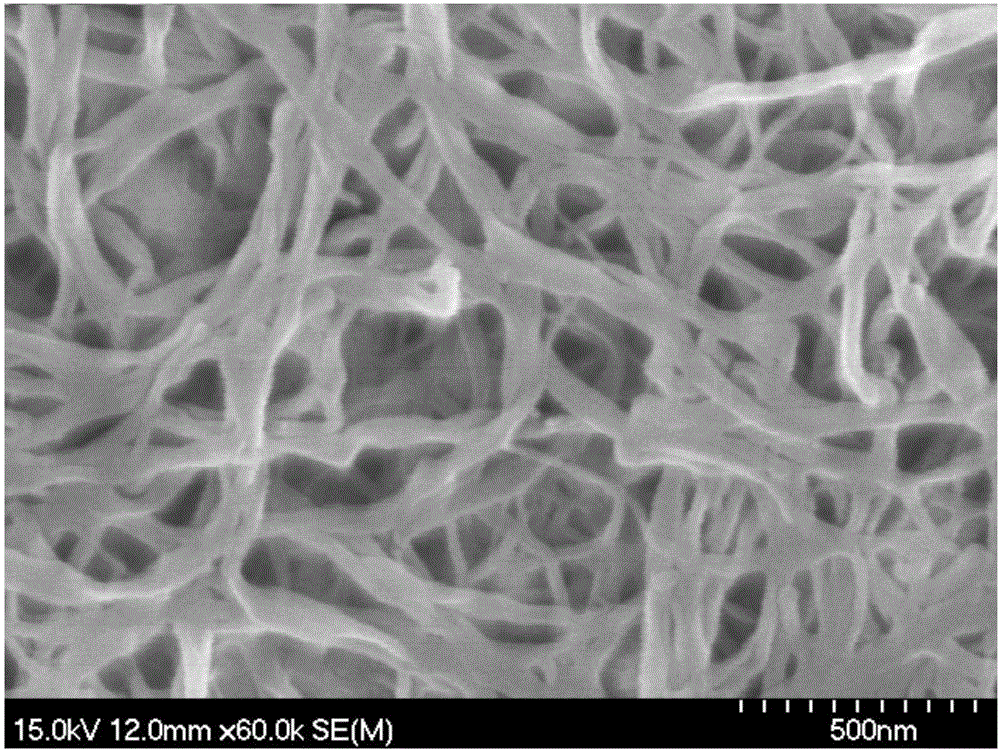

[0045] (1) Preparation of polymer (PEDOT) nanowire film

[0046] Mix EDOT monomer (0.07109g, 0.5mmol), 1-butyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide salt (0.0419g, 0.01mol) and dichloromethane (100mL) to prepare 100 mL of a mixed solution with a monomer concentration of 0.005 mol / L and a supporting electrolyte concentration of 0.1 mol / L was used as the electrolyte. The electrolytic cell adopts a three-electrode system, with FTO conductive glass as the working electrode (sonicated in toluene, acetone, and ethanol for 15 minutes in turn), and polished platinum wire as the auxiliary electrode (the length of the platinum wire is 4 cm), and the reference electrode uses a double liquid Junction-type silver / silver chloride electrode (Ag / AgCl, 3mol / L potassium chloride aqueous solution is used as the first junction, and the electrolyte prepared above is used as the second junction). At room temperature (25°C), the polymer film was prepared by cyclic voltammetry anodi...

Embodiment 3

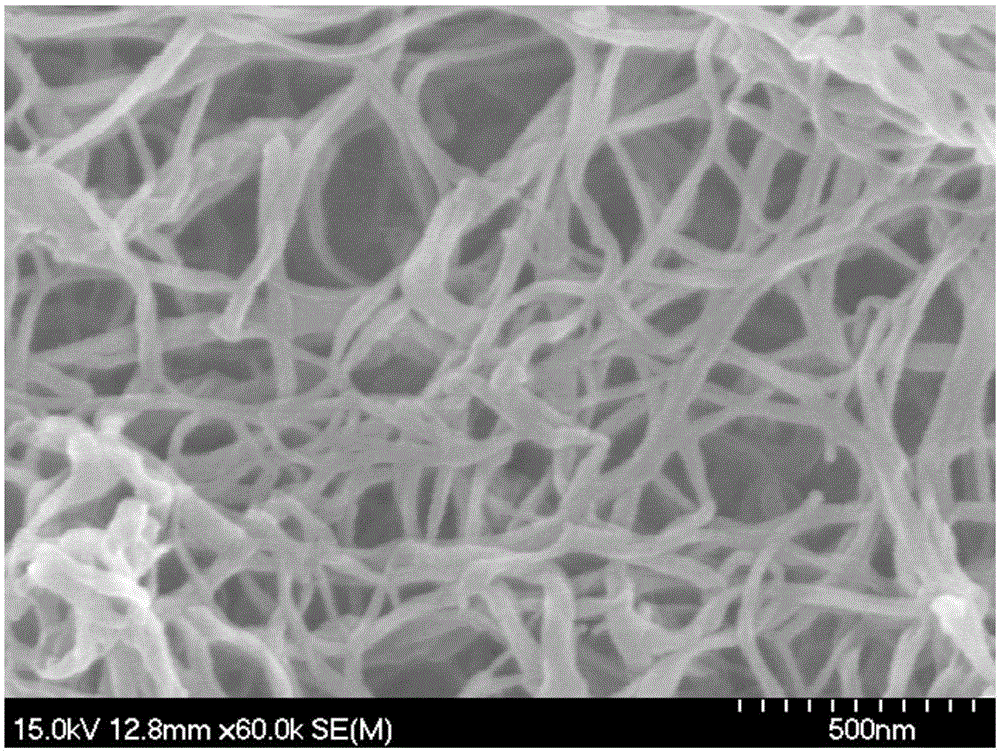

[0048] (1) Preparation of polymer (PEDOT) nanowire film

[0049] Mix EDOT monomer (0.07109g, 0.5mmol), 1-butyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide salt (0.0419g, 0.01mol) and dichloromethane (100mL) to prepare 100 mL of a mixed solution with a monomer concentration of 0.005 mol / L and a supporting electrolyte concentration of 0.1 mol / L was used as the electrolyte. The electrolytic cell adopts a three-electrode system, using a gold sheet (specification 2X2X0.1mm) as the working electrode (sequentially ultrasonically washed in toluene, acetone, and ethanol for 15 min), and using a polished platinum wire as the auxiliary electrode (the length of the platinum wire is 4 cm). The specific electrode adopts a double junction silver / silver chloride electrode (Ag / AgCl, 3mol / L potassium chloride aqueous solution is used as the first junction, and the electrolyte prepared above is used as the second junction). At room temperature (25°C), the polymer film was prepared by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com