Flame-retardant wall-mounted cupboard with fire extinguishing apparatus

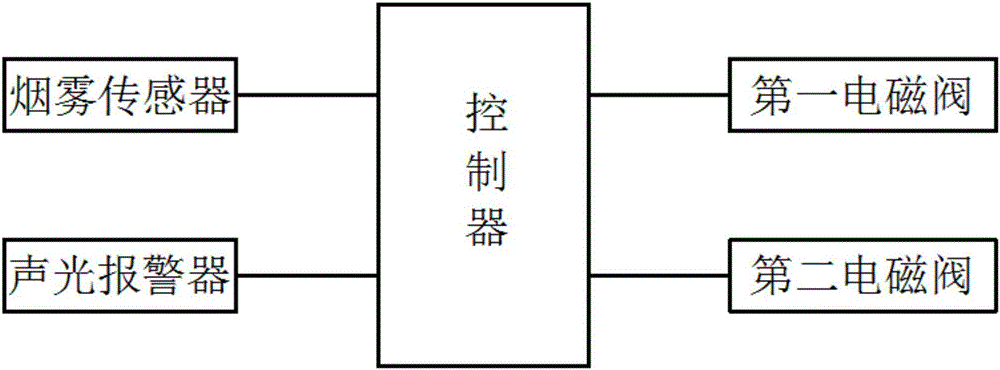

A fire extinguishing device and a wall-mounted technology, applied in the field of cabinets, can solve problems such as easy fire, user life safety threat, and increased fire, and achieve the effects of small specific gravity, prevention of molten droplets, and promotion of charcoal formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 20 parts of polyacrylamide, 15 parts of melamine, 35 parts of ammonium polyphosphate, 3 parts of molybdenum oxide, 3 parts of ammonium molybdate, 8 parts of cyclodextrin, 42 parts of formaldehyde, 12 parts of vermiculite, 18 parts of perlite, phosphoric acid 12 parts of ammonium dihydrogen, 6 parts of nano zinc borate, 32 parts of water.

[0025] The specific steps include: (1) firstly dissolve polyacrylamide, melamine, ammonium polyphosphate and cyclodextrin in formaldehyde according to the formula ratio, then stir evenly and heat to 80°C, react for 22min; then adjust the pH of the above reaction solution (2) Place molybdenum oxide, ammonium molybdate, vermiculite, perlite, ammonium dihydrogen phosphate and nano-zinc borate in water and stir evenly according to the formula ratio, then raise the temperature to 80°C, react for 20 minutes, and then adjust the reaction The pH of the solution is 4-5; (3) Then, mix step (1) and step (2) according to the weight ratio of 1:1 a...

Embodiment 2

[0027] The fireproof coating includes: 24 parts of polyacrylamide, 18 parts of melamine, 28 parts of ammonium polyphosphate, 2 parts of molybdenum oxide, 4 parts of ammonium molybdate, 8 parts of cyclodextrin, 43 parts by weight of formaldehyde, and 18 parts of vermiculite , 28 parts of perlite, 14 parts of ammonium dihydrogen phosphate, 9 parts of nano-zinc borate, and 33 parts of water. The preparation steps are the same as in Example 1.

[0028] The coating prepared by the present invention has no air bubbles, no falling off and no discoloration in the coating film after a 48h test.

[0029] The fire performance of the fireproof board prepared by the present invention is shown in Table 1 below:

[0030] The fire performance of table 1 embodiment 1-2

[0031]

[0032] It is also found that the oxygen index of the sample of Example 1-2 of the present invention is between 40-50 and the formaldehyde emission is less than 1.0 mg / L by testing the fire performance of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com