Fiber thin plate-steel composite reinforced rc structure and its method and application

A thin plate and fiber technology, which is applied in the field of fiber thin plate-steel composite reinforced RC structure, can solve the problems of difficult maintenance and maintenance, difficult construction, brittle failure, etc., and achieve excellent deformation coordination performance, improved reinforcement efficiency, and excellent bending and tensile resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

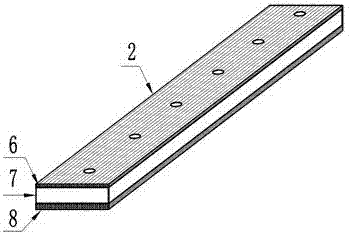

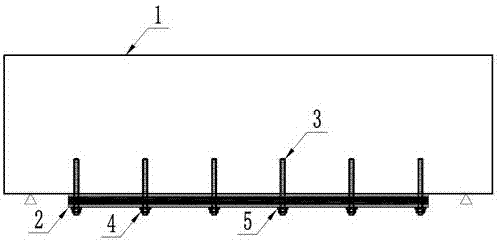

[0050] This example is to adopt the combination of fiber sheet and steel plate in the invention to reinforce the reinforced concrete (RC) slab. Before the reinforcement, according to the relevant concrete reinforcement norms, the composite slab of the present invention is calculated and designed, and the calculated thickness of the fiber sheet is 0.23mm, and the width is 50mm; The steel plate is Q235, the thickness is 3.7mm, and the width is 50mm. The length of the two materials is the same. According to the size of the test piece, both are 1.6m. Then follow the steps below to harden:

[0051] 1) According to the design position, polish the surface of the concrete to be pasted, and drill holes, and blow out the ash in the holes;

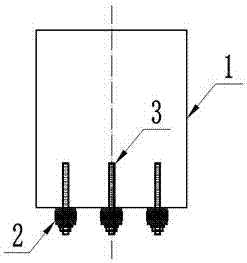

[0052] 2) Implantation with implant glue Figure 6 The M8 high-strength bolt 3 shown in , the depth is 10d, that is, 80mm;

[0053] 3) Drill holes in the steel plate 7 according to the actual implantation positions of the bolts, remove the rust on ...

Embodiment 2

[0064] The method of the present embodiment is the same as the embodiment, except that the first fiber sheet adopts a basalt fiber sheet with a low elastic modulus (the modulus of elasticity is 90Gpa, and the calculated thickness is 0.11mm), and the second fiber sheet adopts a high elastic modulus (230Gpa, 0.11 mm). mm) carbon fiber sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com