Ship propulsion equipment

A technology for propulsion equipment and ships, applied to ship propulsion, propulsion components, ships, etc., can solve problems such as waste of energy, high noise, increase of ship resistance and heavy load, etc., to avoid damage to the ecological environment, reduce environmental noise, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

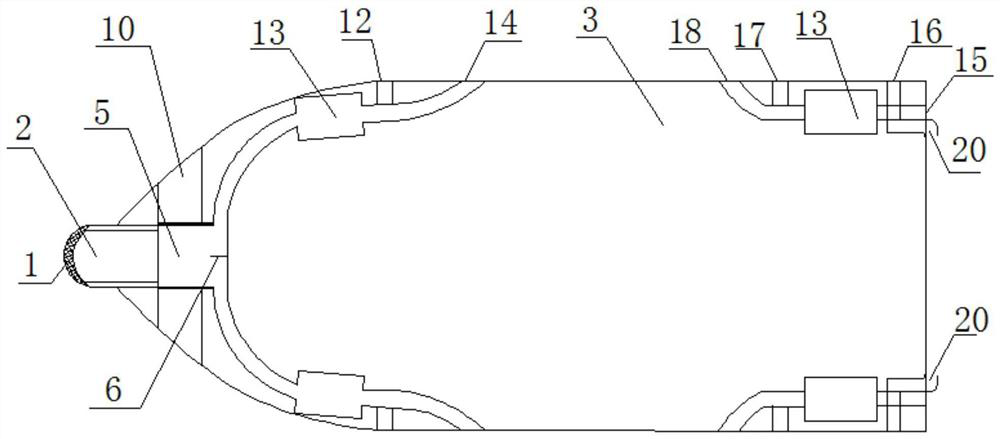

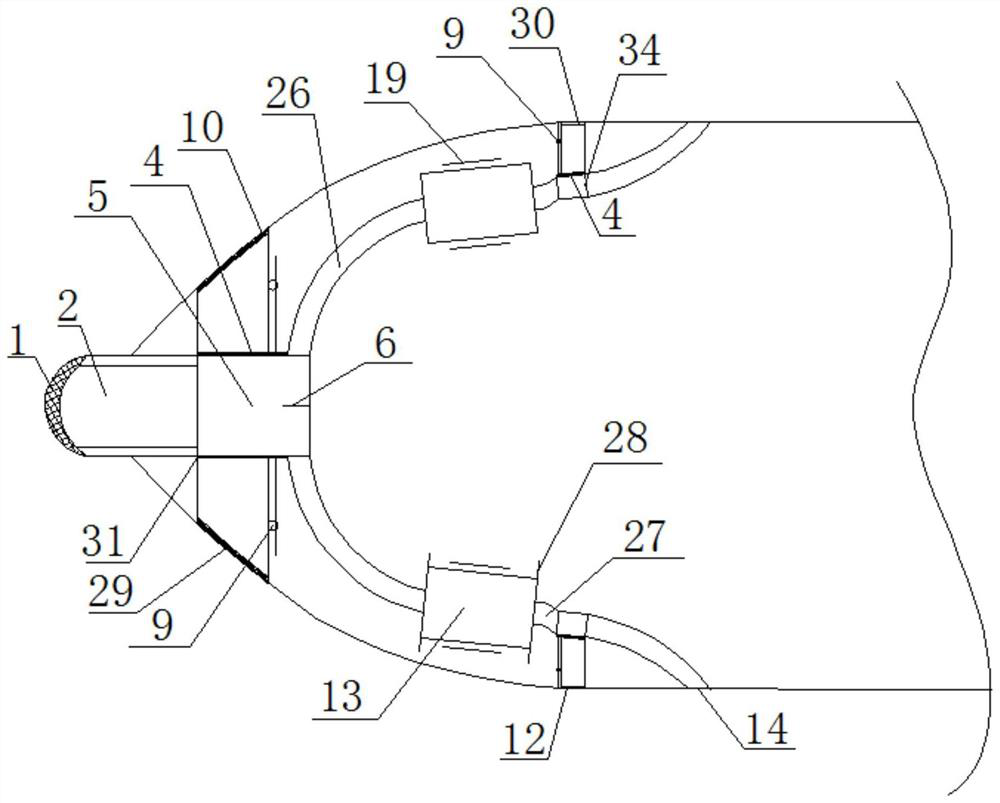

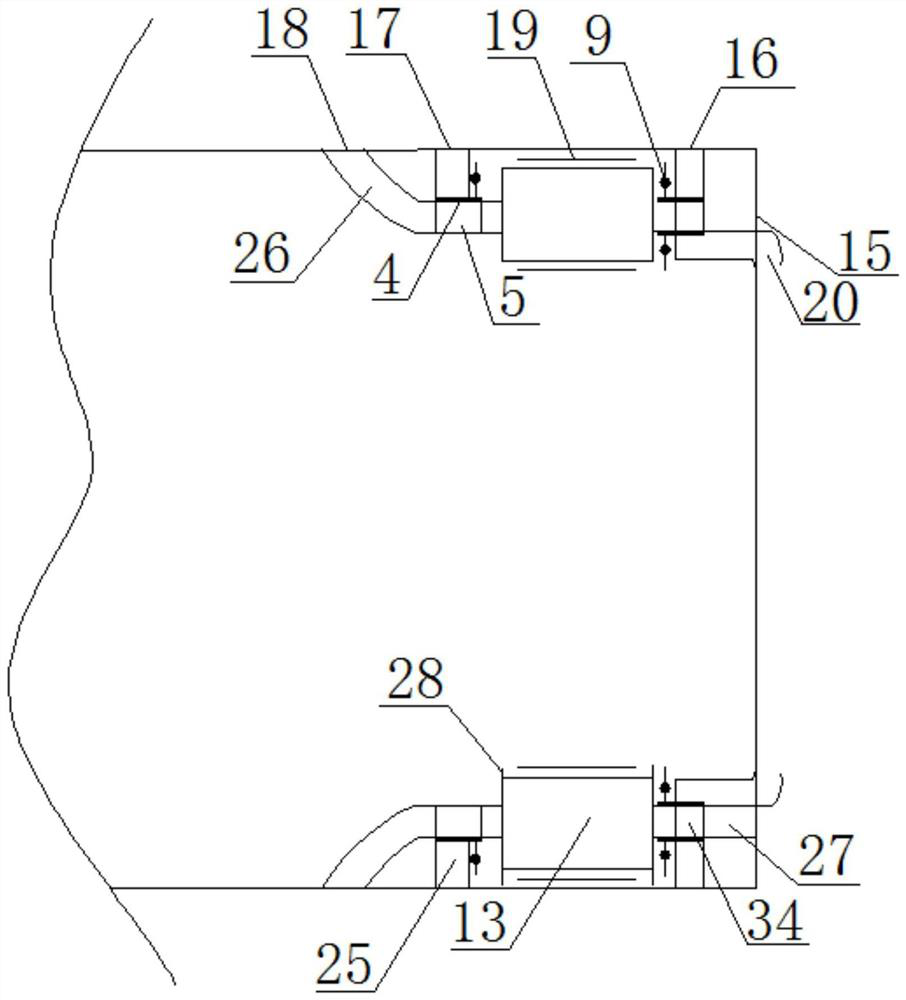

[0049] The implementation mode of the front half of the ship: the two sides of the front half of the ship hull 3 are distributed and installed multi-layer group suction and push equipment bottom plate 23, and the suction and push equipment 13 is installed on the suction and push equipment bottom plate 23, and the two sides are distributed Straight line compound car travel rack track 19, top travel reciprocating car 24, reciprocating push-pull suction push equipment 13 operations. At the front end of the suction pushing device, groups of distribution suction pipes 26 are connected to the end of the diversion box 5 . The front end of the diversion box 5 is distributed and installed to suck forward the main pipeline 2, the net cover and the forward suction inlet 1. Deflectors 4, branch pipes 25, and suction inlet water baffles 29 are distributed on both sides of the diversion box 5. The rear end of the suction and pushing equipment distributes the ejection pipeline 27, the branc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com