Semiconductor device and producing method thereof

一种制造方法、半导体的技术,应用在半导体/固态器件制造、半导体器件、半导体/固态器件零部件等方向,能够解决散热性能限制、限制小型化、薄型化、轻量化等问题,达到减小环境负担、抑制颗粒污染、良好散热性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

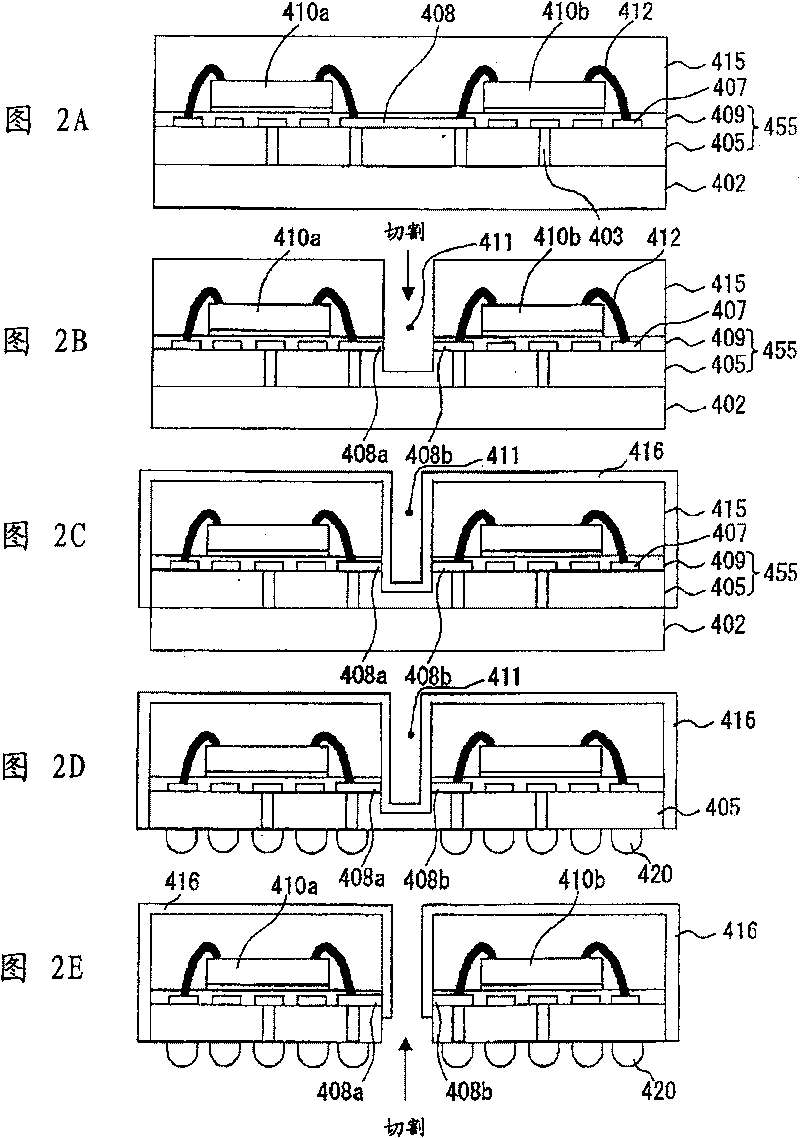

[0039] FIG. 2 is a cross-sectional view showing steps of a method of manufacturing a semiconductor device in an embodiment of the present invention.

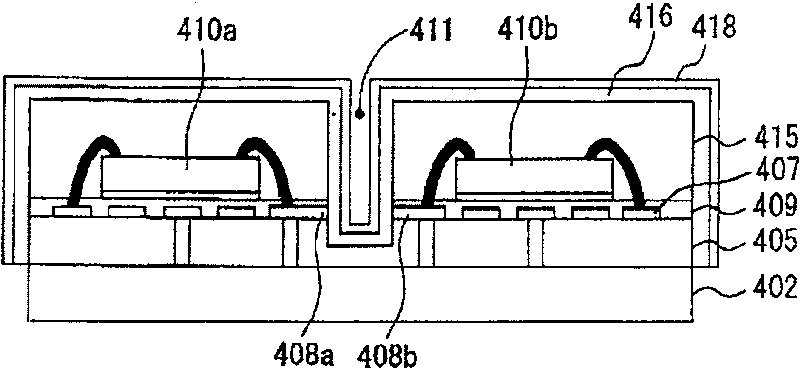

[0040] FIG. 2( a ) shows a laminated body in the process of manufacturing a semiconductor device. Here, the laminate includes: a metal foil 402; a multilayer wiring structure 455 formed on the metal foil 402; a first circuit element 410a and a second circuit element 410b formed on the multilayer wiring structure 455; a cover circuit element 410a and the enclosing film 415 of the circuit element 410b. The multilayer wiring structure 455 has: an interlayer insulating film 405; a coated metal interlayer 403 disposed in the interlayer insulating film 405; a wiring 407 electrically connected to the coated metal interlayer 403 and a cut wiring 408; The wiring 407 and the insulating film 409 of the wiring 408 are cut. Here, the description of the multilayer wiring structure 455 is omitted, but the multilayer wiring structure 455 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com