TiAl-based bulk amorphous alloy and preparation method thereof

A technology of amorphous alloys and large blocks, which is applied in the field of new material manufacturing, can solve problems such as complex shapes of large amorphous alloys, achieve the effect of improving strength and hardness, and improving industrial production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

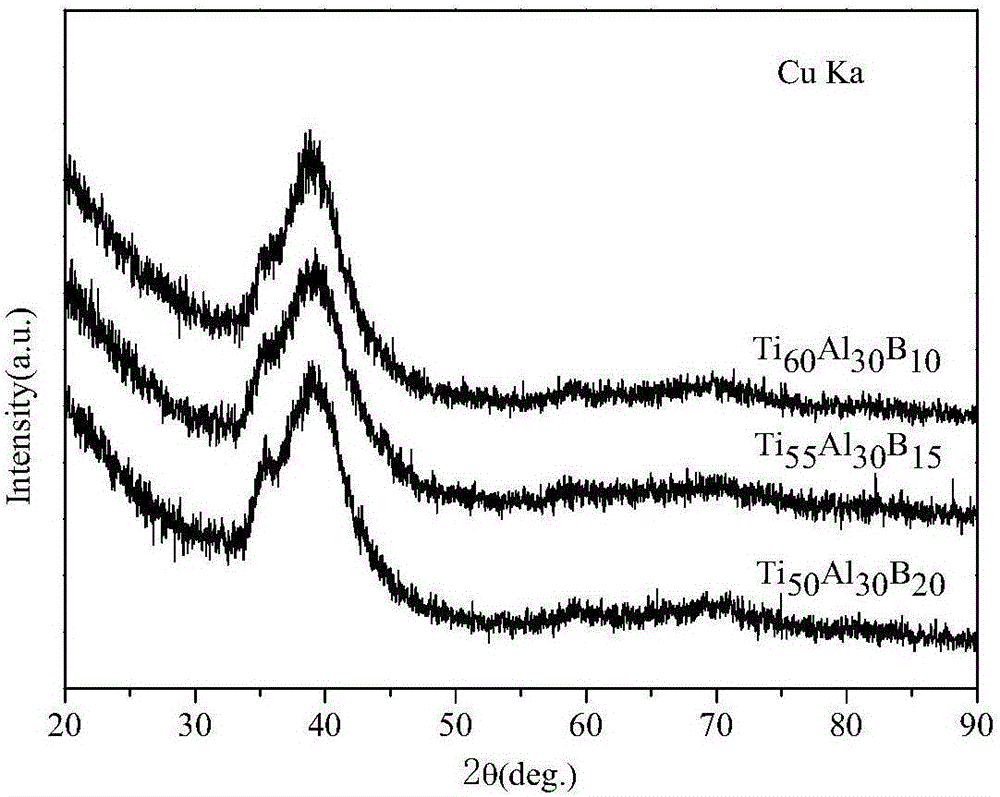

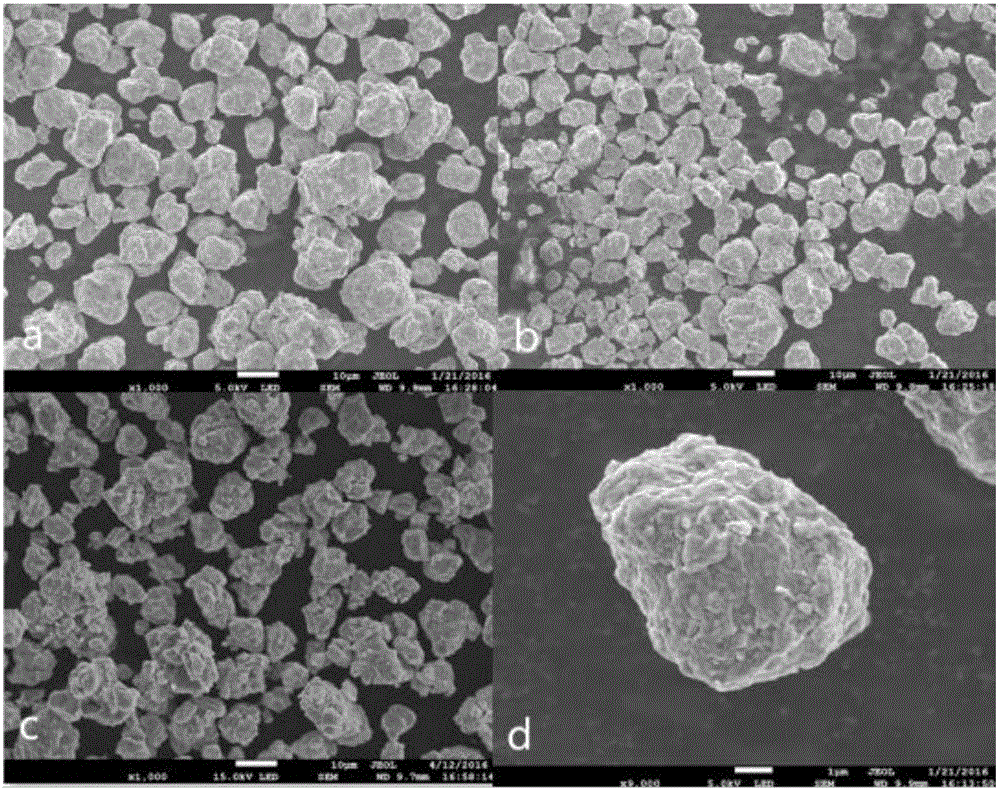

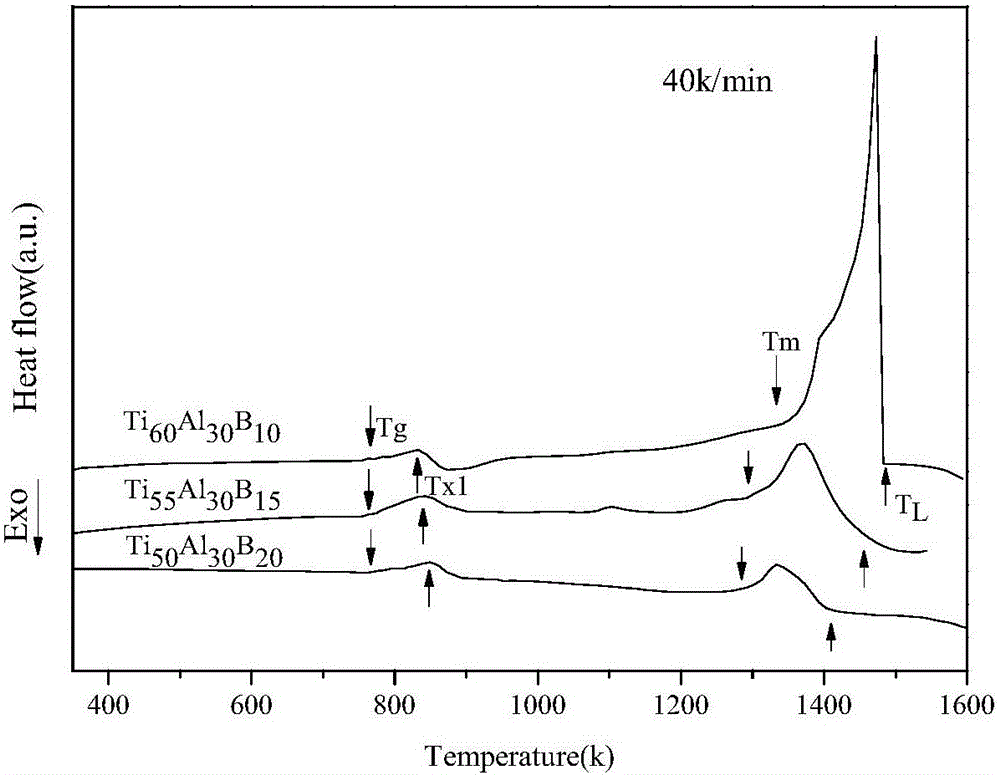

[0037]Preparation of a TiAl-based bulk amorphous alloy. The specific method is: high-purity metal powders Ti (purity 99.99%, 300 mesh), Al (purity 99.99%, 300 mesh), B (purity 99.99%, 300 mesh) are weighed according to the atomic number ratio of 60:30:10 and Carry out ball milling, pass into high-purity argon in the ball milling tank and protect, the ball mill rotating speed is 350r / min, the ball material ratio is 30: 1 (the grinding balls are respectively mixed with large, medium and small, and its diameter is 20mm, 8mm, 6mm The general ratio is Φ20:Φ8:Φ6=3:100:500. The following examples are the same), and the amorphous powder is obtained after ball milling for 40 hours in the manner of "running for 30 minutes, stopping for 12 minutes, and then running in reverse for 30 minutes".

[0038] The prepared amorphous powder is pre-pressed at 20Mpa and subjected to spark plasma sintering, the block is placed in a graphite mold, and the temperature is raised to 1073K at a rate of 40...

Embodiment 2

[0044] Preparation of a TiAl-based bulk amorphous alloy. The specific method is: high-purity metal powders Ti (purity 99.99%, 300 mesh), Al (purity 99.99%, 300 mesh), B (purity 99.99%, 300 mesh) are weighed according to the atomic ratio of 55:30:15 and carried out For ball milling, high-purity argon gas is introduced into the ball mill tank for protection, the ball mill speed is 350r / min, the ball-to-material ratio is 30:1, and after 40 hours of ball milling in the manner of "running for 30 minutes, stopping for 12 minutes, and then running in reverse for 30 minutes", the obtained Amorphous powder.

[0045] The prepared amorphous powder is pre-pressed at 20Mpa and subjected to spark plasma sintering, the block is placed in a graphite mold, and the temperature is raised to 1073K at a rate of 40k / min at 40Mpa, kept for 10min, and then cooled with the furnace. An amorphous bulk alloy is obtained.

[0046] The sintered block is subjected to XRD diffraction analysis, see Figure...

Embodiment 3

[0049] Preparation of a TiAl-based bulk amorphous alloy. The specific method is: high-purity metal powders Ti (purity 99.99%, 300 mesh), Al (purity 99.99%, 300 mesh), B (purity 99.99%, 300 mesh) are weighed according to the atomic ratio of 50:30:20 and carried out For ball milling, high-purity argon gas is introduced into the ball mill tank for protection, the ball mill speed is 350r / min, the ball-to-material ratio is 30:1, and after 40 hours of ball milling in the manner of "running for 30 minutes, stopping for 12 minutes, and then running in reverse for 30 minutes", the obtained Amorphous powder.

[0050] The prepared amorphous powder is pre-pressed at 20Mpa and subjected to spark plasma sintering, the block is placed in a graphite mold, and the temperature is raised to 1073K at a rate of 40k / min at 40Mpa, kept for 10min, and then cooled with the furnace. An amorphous bulk alloy is obtained.

[0051] The sintered block is subjected to a three-point bending strength test, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial crystallization temperature | aaaaa | aaaaa |

| Initial crystallization temperature | aaaaa | aaaaa |

| Initial crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com