Carbon tube masterbatch and its application in tire tread

A tire tread and masterbatch technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of restricting the large-scale application of carbon nanotubes, poor affinity of polymer matrix, and poor dispersion of carbon nanotubes , to achieve the effect of improving the braking distance, good antistatic performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

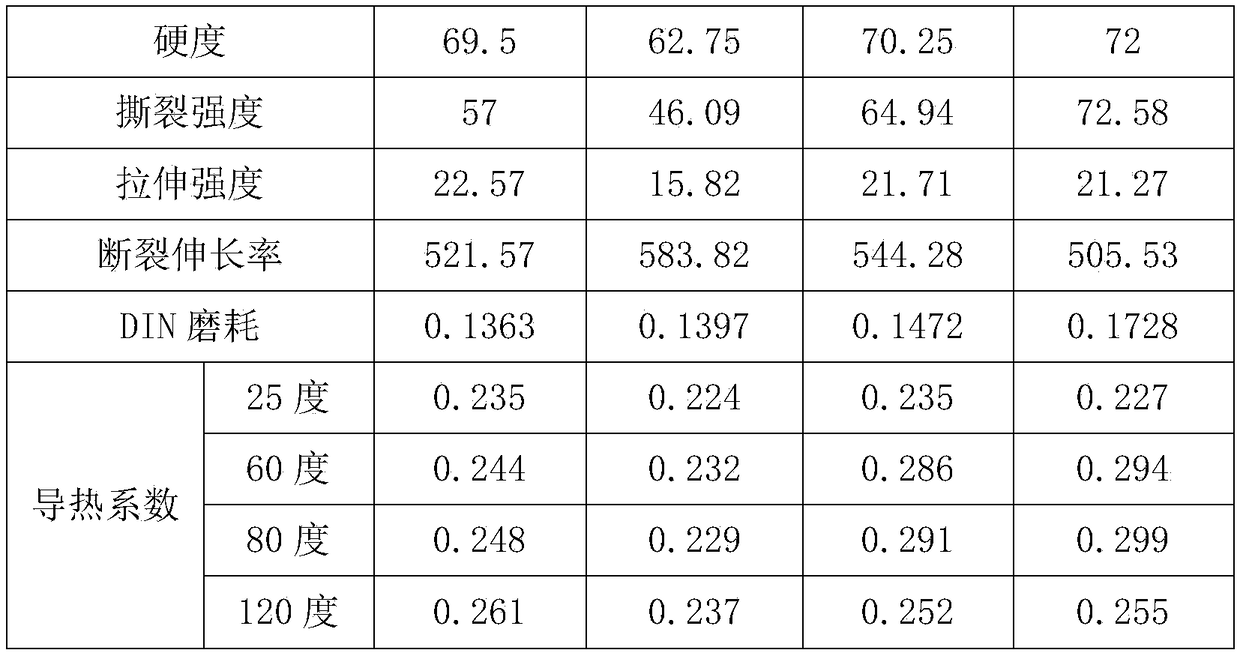

Embodiment 1-4

[0016] Preparation of embodiment 1-4 carbon tube masterbatch and its application in tire tread

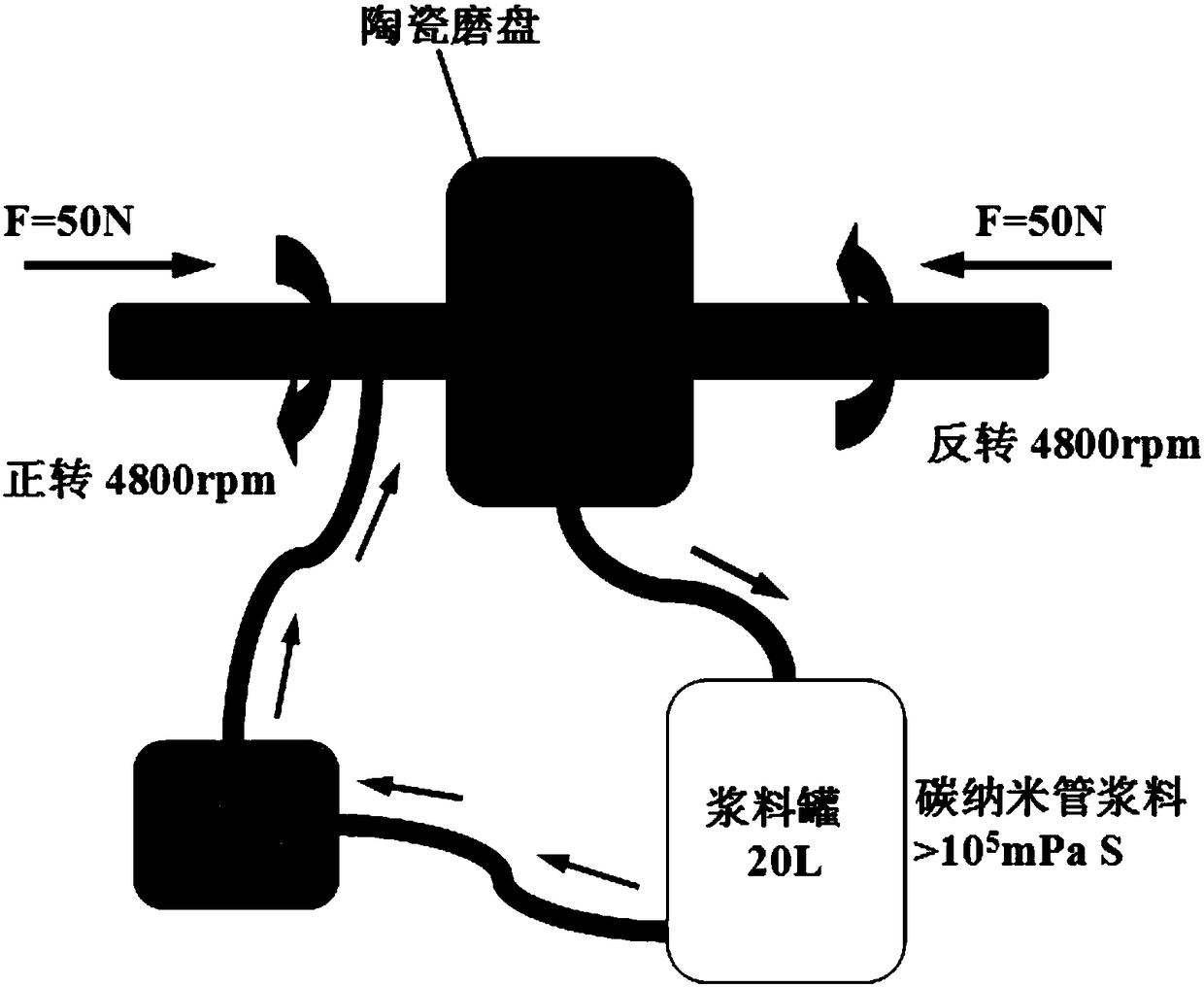

[0017] Step 1, the dispersion of carbon nanotubes (such as figure 1 shown): First, the carbon nanotubes are added to the rubber polymer melt and stirred to form a carbon nanotube slurry, and then injected into a grinding device with a line-contact double ceramic grinding disc through a material pump for grinding, and the two ceramic grinding discs turn in opposite directions , the speed is controlled at 4800rpm, so that the carbon nanotubes are uniformly dispersed in the polymer, and the carbon nanotubes are cut off under the action of mechanical friction and interlayer shear force in the polymer melt, and the polymer is removed to obtain a length of 50nm~ 5 μm short carbon nanotubes;

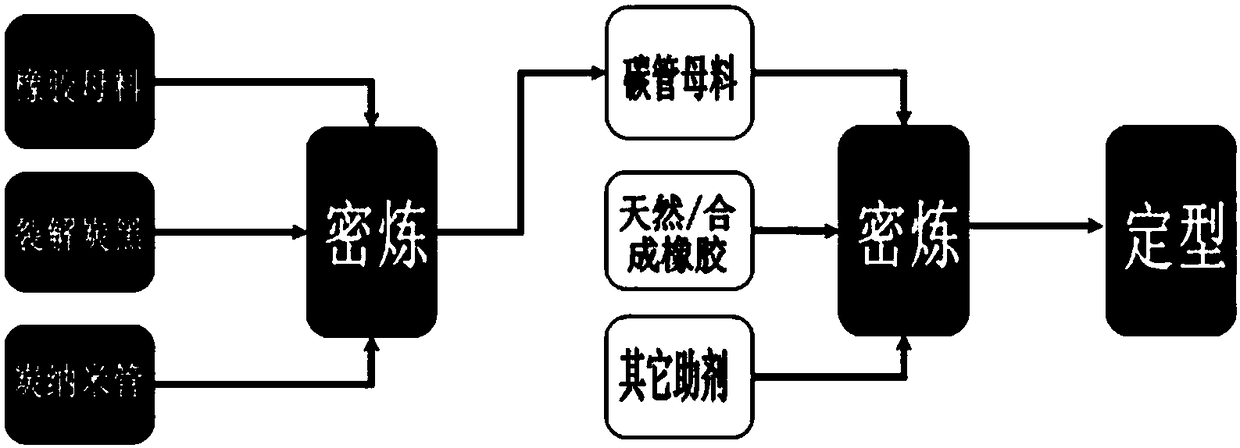

[0018] Step 2, mixing together the rubber masterbatch (the composition is rubber), carbon black (using pyrolysis carbon black), and the short carbon nanotubes obtained in step 1, and performing ban...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com