Production process of casting iron coating-free stainless liner of electric cooker

A production process and technology of electric cooker, which are applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as easy to get dementia, and achieve the effects of wide source, improved corrosion resistance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

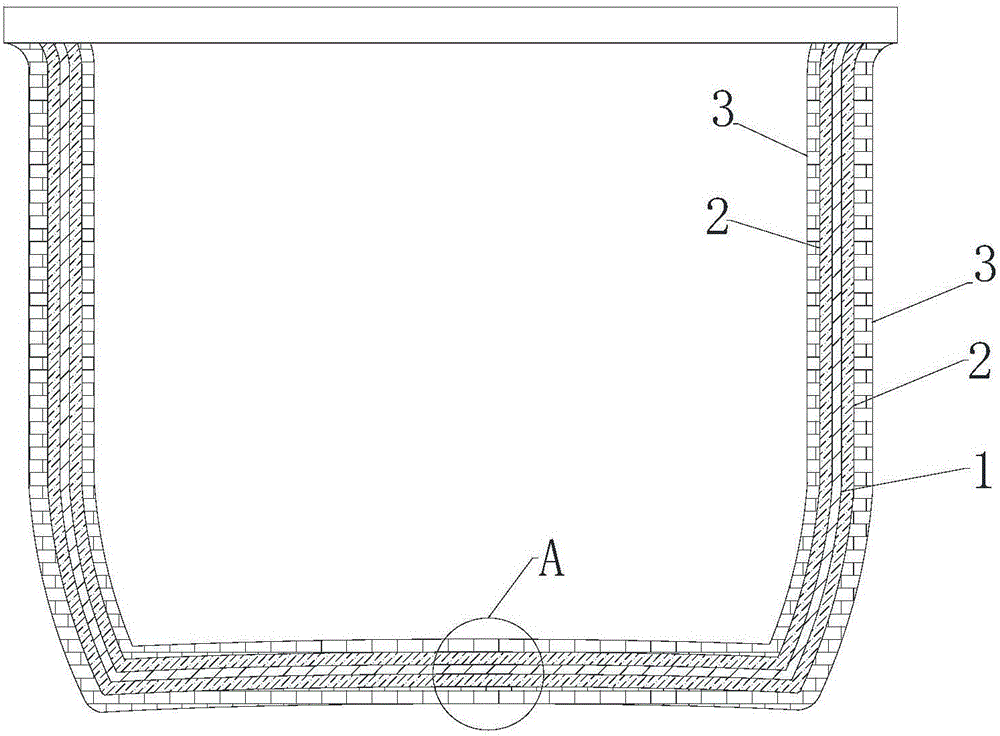

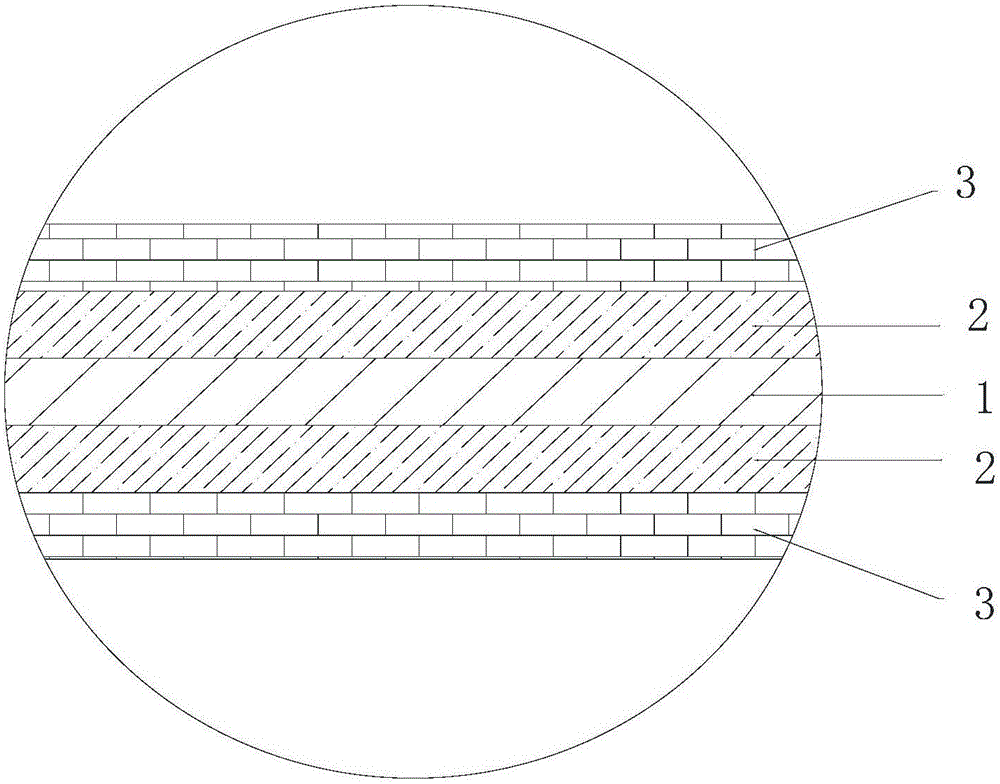

Image

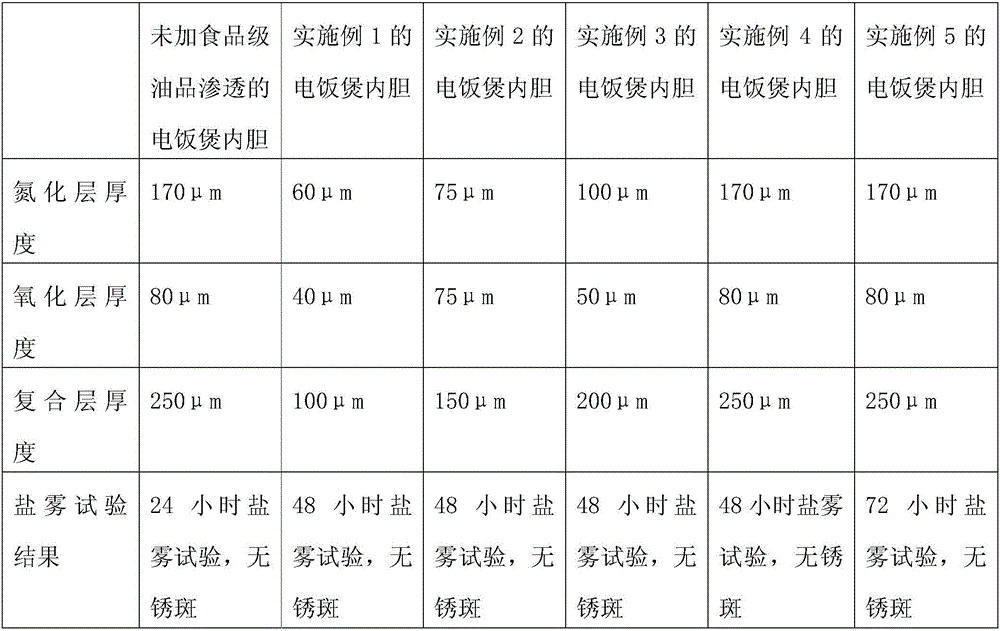

Examples

Embodiment 1

[0036] 1. Pretreatment of the blank of the inner pot of the rice cooker

[0037]Select high-quality pig iron to cast the blank of the inner pot of the electric rice cooker for machining according to the size requirements of the drawing. During the processing, there should be no casting defects such as pinholes and pores; then use a polishing machine to polish the inner pot of the electric rice cooker to make the surface roughness reach 3.2 , you can get the rice cooker liner.

[0038] 2. Production process of rice cooker liner

[0039] (1) Into the furnace: place the blank of the inner pot of the electric rice cooker with a special work frame at room temperature, keep a gap of 2 cm between the inner pot and the inner pot, and then put it into the furnace;

[0040] (2) Nitrogen filling: Seal the furnace immediately after the rice cooker liner enters the furnace, then start the rotary vane vacuum pump to vacuumize the furnace until the pressure in the furnace is -0.1Mpa, and th...

Embodiment 2

[0045] 1. Pretreatment of the blank of the inner pot of the rice cooker

[0046] Select high-quality pig iron to cast the blank of the inner pot of the electric rice cooker for machining according to the size requirements of the drawing. During the processing, there should be no casting defects such as pinholes and pores; then use a polishing machine to polish the inner pot of the electric rice cooker to make the surface roughness reach 3.2 , you can get the rice cooker liner.

[0047] 2. Production process of rice cooker liner

[0048] (1) Into the furnace: place the blank of the inner pot of the electric rice cooker with a special work frame at room temperature, keep a gap of 2 cm between the inner pot and the inner pot, and then put it into the furnace;

[0049] (2) Nitrogen filling: Seal the furnace immediately after the rice cooker liner enters the furnace, then start the rotary vane vacuum pump to vacuumize the furnace until the pressure in the furnace is -0.1Mpa, and t...

Embodiment 3

[0054] 1. Pretreatment of the blank of the inner pot of the rice cooker

[0055] Select high-quality pig iron to cast the blank of the inner pot of the electric rice cooker for machining according to the size requirements of the drawing. During the processing, there should be no casting defects such as pinholes and pores; then use a polishing machine to polish the inner pot of the electric rice cooker to make the surface roughness reach 3.2 , you can get the rice cooker liner.

[0056] 2. Production process of rice cooker liner

[0057] (1) Into the furnace: place the blank of the inner pot of the electric rice cooker with a special work frame at room temperature, keep a gap of 2 cm between the inner pot and the inner pot, and then put it into the furnace;

[0058] (2) Nitrogen filling: Seal the furnace immediately after the rice cooker liner enters the furnace, then start the rotary vane vacuum pump to vacuumize the furnace until the pressure in the furnace is -0.1Mpa, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com