Application of liquid enzyme preparation in improvement of food texture

A liquid enzyme and preparation technology, applied in the field of food processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

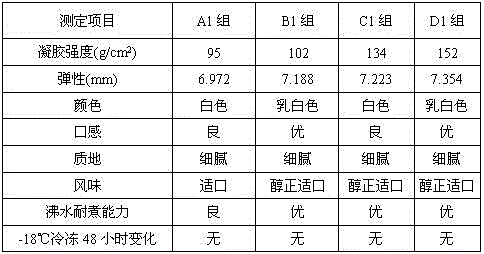

[0050] The application of a liquid enzyme preparation in products containing isolated soybean protein. The liquid transglutaminase product (enzyme activity 100U / mL, Shanghai Qingrui Food Technology Co., Ltd.) was applied to the preparation of thousand-sheet tofu. The manufacturer of isolated soybean protein was For Shandong Yuwang Group, cassava modified starch was Rose brand, soybean oil was supplied by COFCO Group, monosodium glutamate and salt were purchased from Metro Supermarket, and the addition amount of liquid transglutaminase in groups A1, B1, C1, and D1 was 10, 20, 30. 40U / 100g total material weight, make thousand-sheet tofu according to the formula in Table 5 and the following processing technology.

[0051] Table 5. Formula of liquid transglutaminase for the production of thousand-sheet tofu

[0052]

[0053] The processing process is as follows:

[0054] (1) Chop and mix: Add soybean protein isolate to a 250L chop and mix pot according to the above formula, ad...

Embodiment 2

[0063] Application of a liquid enzyme preparation in products containing pork protein. Liquid glutamine transaminase product (enzyme activity 100U / mL, Shanghai Qingrui Food Technology Co., Ltd.) was applied to the preparation of sausages. The producer of soybean protein isolate was Shandong Yuwang Group, cassava modified starch is rose brand, compound phosphate is provided by Wuhan Ancient Wood Biotechnology, lean pork, pig fat, monosodium glutamate, spices, white sugar and salt are purchased from Metro Supermarket, liquid grain in groups A2, B2, C2 and D2 The amount of aminotransferase added is 10, 20, 30, 40U / 100g of total material weight respectively, and the sausage is made according to the formula in Table 7 and the following processing technology.

[0064] Table 7. Recipe of liquid transglutaminase for sausage production

[0065]

[0066] The processing process is as follows, according to the conventional processing technology of sausage:

[0067] (1) Thaw the meat a...

Embodiment 3

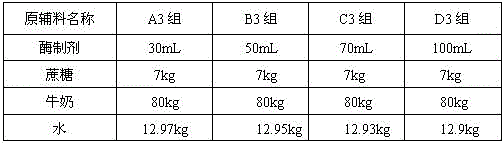

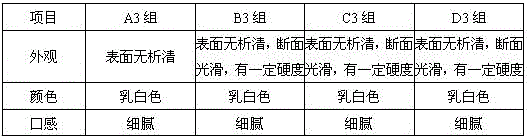

[0077] The application of a liquid enzyme preparation in casein-containing products, the liquid transglutaminase product (enzyme activity 100U / mL, Shanghai Qingrui Food Technology Co., Ltd.) was applied to the preparation of yogurt, the milk was Guangming brand, and the sucrose was purchased from Metro In the supermarket, the addition amount of liquid transglutaminase in groups A3, B3, C3, and D3 is 3, 5, 7, and 10 U / 100g of total material weight respectively, and the yogurt is made according to the formula in Table 9 and the following process.

[0078] Table 9. Recipe of liquid transglutaminase for yogurt production

[0079]

[0080] The production process is as follows:

[0081] Preheat milk (60-65°C) → add sucrose → stir for 10 minutes → sterilize (90-95°C, 5 minutes) → cool down → add enzyme preparation and stir well → keep warm at 37°C for 1 hour → inoculate → ferment until the acidity is about 85 → 2~ After fermentation at 8°C for 12 hours → the product is obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com