High-strength steel sheet and high-strength steel pipe having excellent hydrogen-induced cracking resistance for use in line pipe

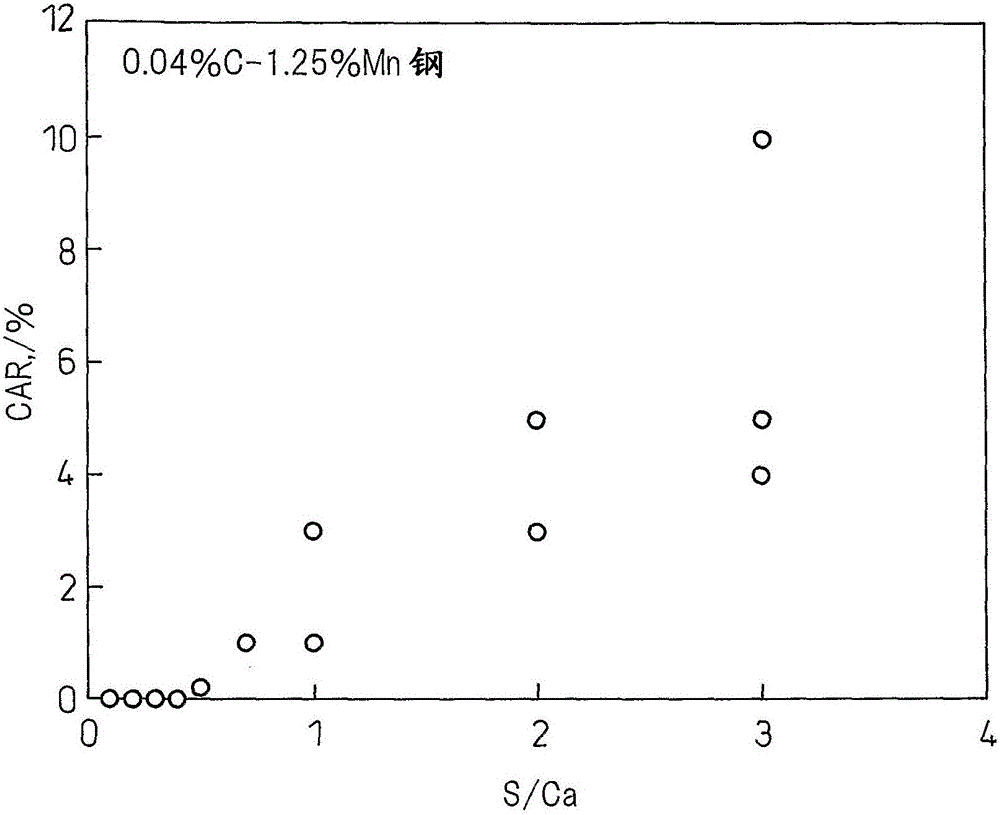

A hydrogen-induced cracking resistance and high-strength technology, applied in the field of hydrogen-induced cracking resistance (hydrogen-induced crack resistance), can solve the problems of easy crack expansion and other problems, and achieve the effects of significant contribution, rise suppression, and segregation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

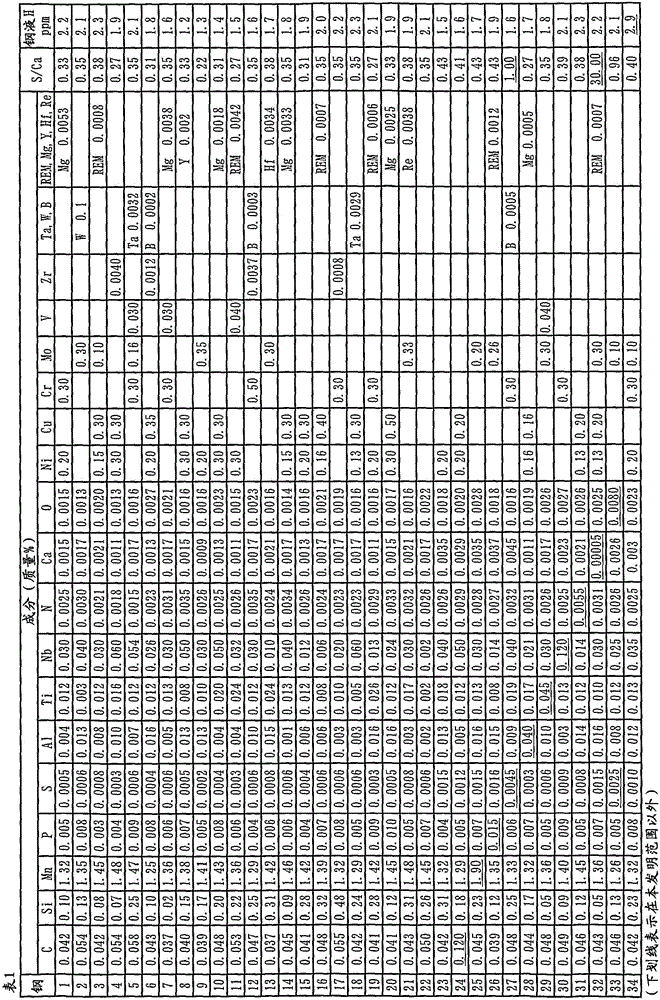

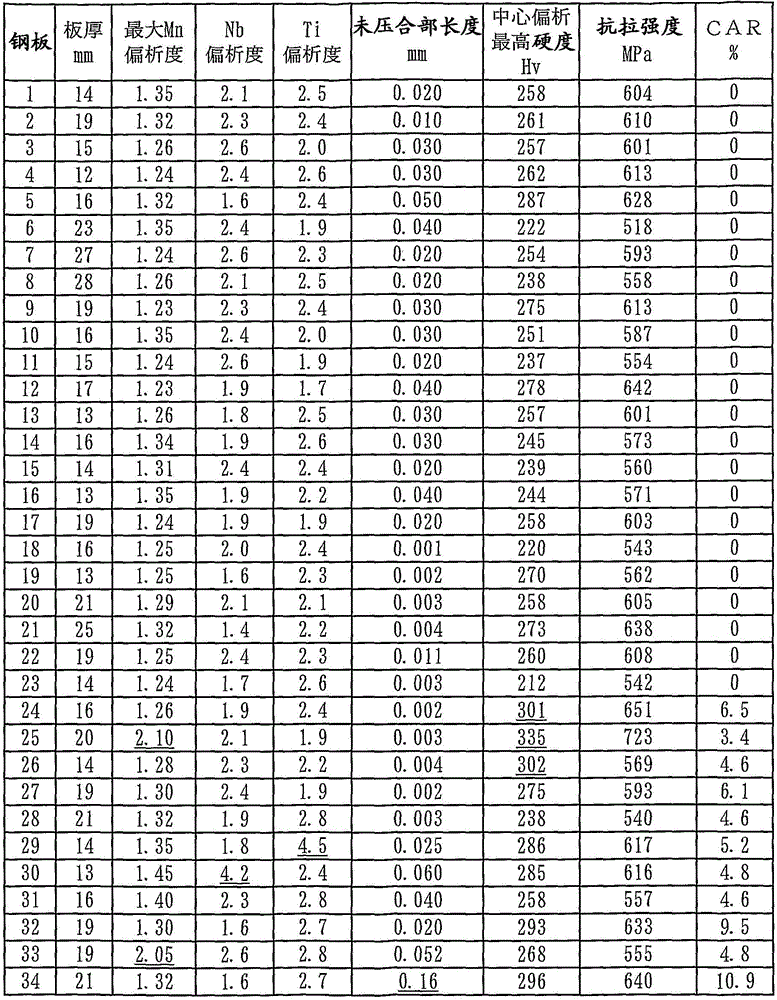

[0168] Next, the present invention will be described in more detail by way of examples.

[0169] Steels having the chemical compositions shown in Table 1 were melted and continuously cast to produce billets with a thickness of 240 mm. In addition, Table 1 also shows the analysis value of the hydrogen content of molten steel. In continuous casting, light reduction at the time of final solidification is performed. The obtained slab is heated to 1000-1250°C, hot-rolled in a recrystallization temperature range exceeding 900°C, and then hot-rolled in a non-recrystallization temperature range of 750-900°C. After hot rolling, water cooling was started at 750° C. or higher, and water cooling was stopped at a temperature of 400 to 500° C., and steel sheets with various thicknesses shown in Table 2 were produced.

[0170] Furthermore, the steel plate is formed into a tube by C stamping, U stamping, and O stamping, the end faces are tack welded, the inner and outer surfaces are fully w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com