Method for preparing lipopeptide biological surfactant

A technology of biological surface and active agent, applied in the biological field, can solve the problems of complicated separation and purification process, long fermentation period and high cost of raw materials, and achieve the effects of cheap and easy-to-obtain raw materials, short fermentation period and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Strain screening

[0028] The salt-tolerant Brevibacterium Y-1-4 of the present invention is screened using the following method, and the specific steps are as follows:

[0029] (1) Spot the 317 strains of bacteria that have been isolated and purified from the soil on the blood plate and cultivate them at 30-37°C for 12-24 hours.

[0030] (2) Select the strain with the larger hemolytic circle in step (1) for the oil discharge circle test.

[0031] (3) The blood plate in step (1) was purchased from Beijing Luqiao Technology Co., Ltd.

[0032] (4) The specific steps of the oil drain ring experiment used in step (2): Take a petri dish with a diameter of 9 cm, add 20 mL of distilled water, and drop 200 μL of liquid paraffin into the center of the water to slowly form a thin oil film. Slowly add 10μL of supernatant to the liquid paraffin and measure the diameter of the oil drain ring. The strain with the largest oil discharge ring (7.5cm) is Brevibacterium halotolerans Y-1-4.

[0033...

Embodiment 2

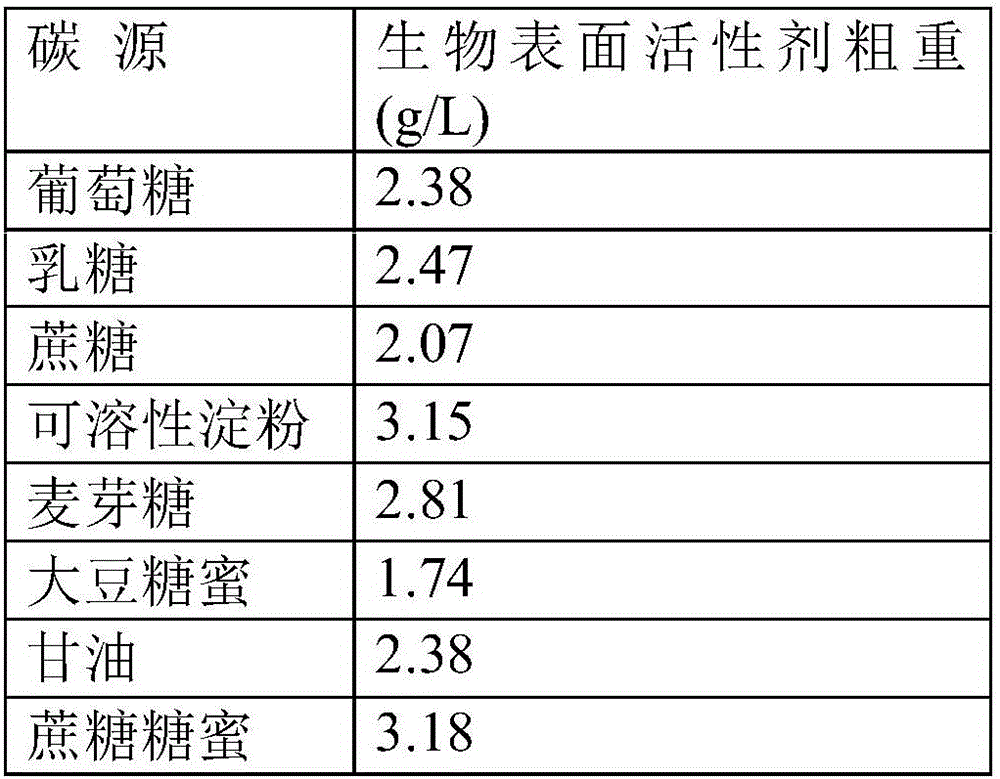

[0038] Utilization of Carbon Source by Brevibacterium halotolerans Y-1-4

[0039] Brevibacterium halotolerant Y-1-4 can use various carbon sources to produce lipopeptide biosurfactants, mainly glucose, lactose, sucrose, soluble starch, maltose, soybean molasses, glycerin, sucrose molasses. Other components are: yeast powder 3g / L, K 2 HPO 4 3g / L, NaH 2 PO 4 3g / L, MgSO 4 0.1g / L, FeSO 4 0.05g / L, NaCl 5g / . The carbon source concentration is 2%L, the sample volume is 50mL / 250mL Erlenmeyer flask, the inoculation volume is 4%, the culture temperature is 30°C, and the shaker speed is 160rpm. The results are shown in Table 1 below.

[0040] Table 1 shows the crude weight of biosurfactants corresponding to different carbon sources

[0041]

Embodiment 3

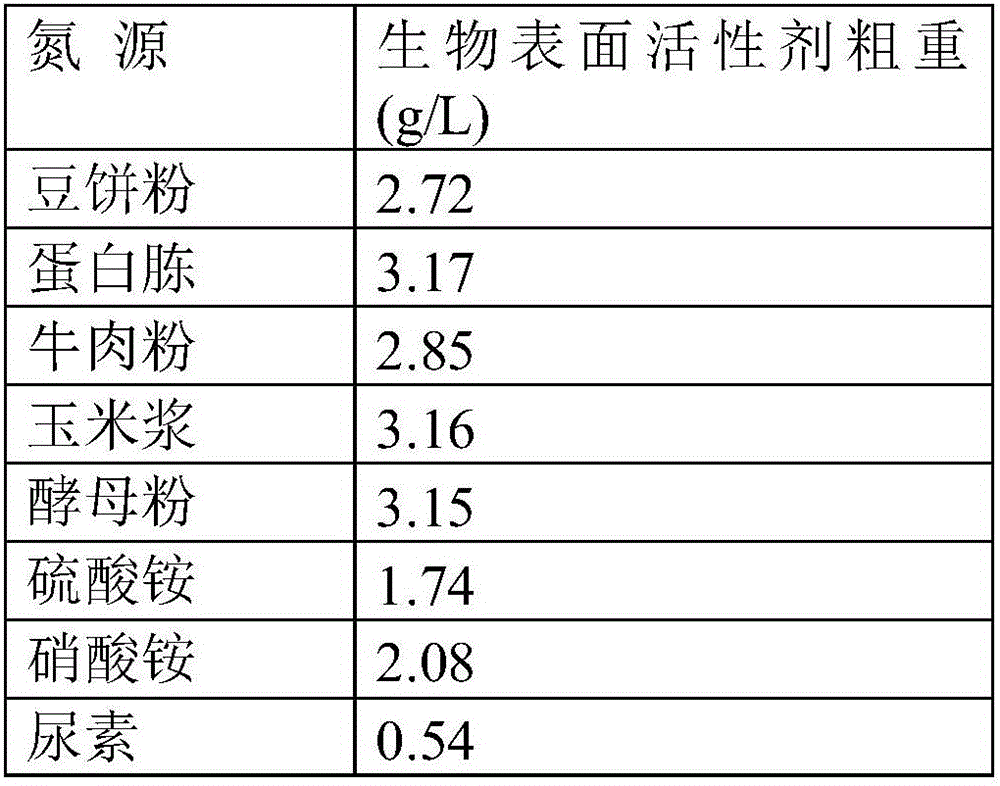

[0043] Utilization of Nitrogen Source by Brevibacterium halotolerans Y-1-4

[0044] Brevibacterium halotolerant Y-1-4 can use various nitrogen sources to produce lipopeptide biosurfactants, mainly including soybean meal, peptone, beef powder, corn steep liquor, yeast powder, ammonium nitrate, ammonium sulfate, and urea. Other components are: sucrose molasses 20g / L, K 2 HPO 4 3g / L, NaH 2 PO 4 3g / L, MgSO 4 0.05g / L, FeSO 4 0.1g / L, NaCl 4g / L. The nitrogen source concentration is 3g / L, the sample volume is 50mL / 250mL Erlenmeyer flask, the inoculation volume is 5%, the culture temperature is 28°C, and the shaker rotation speed is 140rpm. The results are shown in Table 2 below.

[0045] Table 2 shows the crude weight of biosurfactants corresponding to different nitrogen sources

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

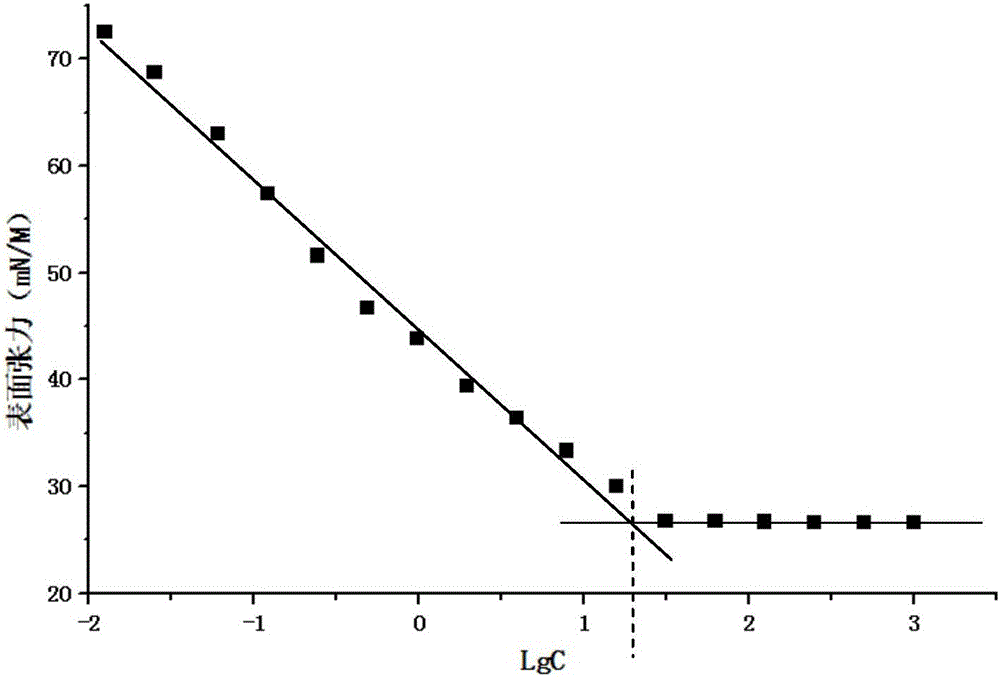

| Critical micelle concentration | aaaaa | aaaaa |

| Surface tension value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com