Method for resource utilization of Fenton iron mud

A technology of resource utilization and iron sludge, applied in chemical instruments and methods, iron sulfate, sludge treatment, etc., can solve problems such as affecting product quality, and achieve the effects of reducing air pollution, simplifying post-processing steps, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

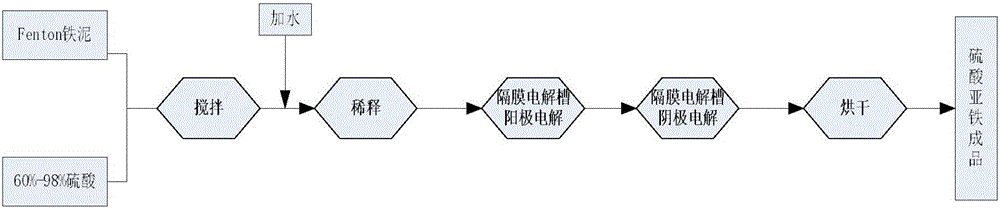

Method used

Image

Examples

Embodiment 1

[0027] The wastewater from a pesticide factory was treated with Fenton technology to obtain Fenton iron sludge.

[0028] Step 1, in above-mentioned iron slime, add the vitriol oil of 98% while stirring, make Fe(OH) 3 fully reacted to Fe 2 (SO 4 ) 3 , control the pH of the solution to be 1-3 to obtain the iron slime solution, add industrial cooling water, stop adding water when the solubility of iron ions is 87.12g / L, and measure the pH of the solution at this time to be 2, and the COD to be 620mg / L .

[0029] Step 2: The diaphragm electrolyzer with Ru-Ir / Ti as the anode and the graphite plate as the cathode is the electroreduction device, and the diaphragm adopts an anion exchange membrane with a current density of 20mA / cm 2 , transfer the solution obtained in step 1 into the anode reaction chamber for oxidation treatment, react for 1h, measure the COD of the solution to be 60mg / L, reduce the COD of the iron slime solution obtained by the treatment by 90%, and measure the ...

Embodiment 2

[0033] Wastewater from a dye factory was treated with Fenton technology to obtain Fenton iron sludge. It turned out that the factory mainly disposed of the iron sludge through landfill, but after inspection, the Fenton iron sludge buried by the factory seriously affected the local soil and brought secondary pollution.

[0034] Step 1, now take the Fenton iron mud of this factory, and stir while adding 98% concentrated sulfuric acid to make Fe(OH) 3 fully reacted to Fe 2 (SO 4 ) 3 , Control the pH of the solution to be 1-3 to obtain an iron slime solution, add industrial condensed water, stop adding water when the solubility of iron ions is 88.70g / L, at this time, the measured pH of the solution is 1.5, and the COD is 1000mg / L.

[0035] Step 2: The diaphragm electrolyzer with Ru-Ir / Ti as the anode and the graphite plate as the cathode is the electroreduction device, and the diaphragm adopts a cation exchange membrane with a current density of 20mA / cm 2 , transfer the soluti...

Embodiment 3

[0039] The wastewater from a chemical intermediate production enterprise was treated with micro-electrolysis-Fenton to obtain Fenton iron sludge.

[0040] Step 1, now take the Fenton iron mud of this factory, and stir while adding 80% concentrated sulfuric acid, so that Fe(OH) 3 fully reacted to Fe 2 (SO 4 ) 3 , Control solution pH to be 1-3, obtain iron slime solution, add product washing water, stop adding water when the solubility of iron ion is 80g / L, record solution pH this moment and be 1, COD is 6000mg / L.

[0041] Step 2: The diaphragm electrolyzer with Ru-Ir / Ti as the anode and the graphite plate as the cathode is the electroreduction device, and the diaphragm uses a cation exchange membrane with a current density of 30mA / cm 2 , transfer the solution obtained in step 1 into the anode reaction chamber for oxidation treatment, react for 2 hours, measure the COD to be 4700 mg / L, and measure the total iron ion content to be 79.5 g / L. The anode effluent enters the anode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com