Cold-machining technology for high-precision optical lenses

A technology of optical lens and processing technology, which is applied in the direction of metal processing equipment, optical surface grinder, manufacturing tools, etc., can solve the problems of slow processing speed and unsatisfactory precision of high-precision optical lens in classical processing methods, so as to ensure the quality of lens processing, The effect of shortening the process flow and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

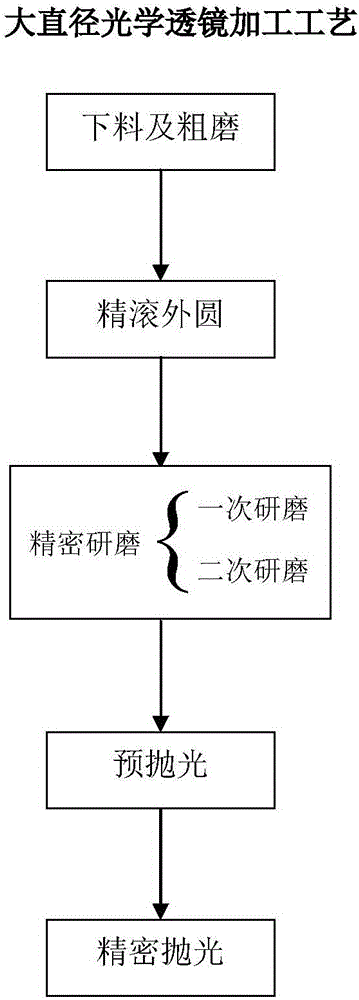

[0069] according to figure 1 The process flow shown is to process large-diameter optical lenses, cut quartz raw materials into squares, rough grind to modify the thickness, fine roll the outer circle, mill the radius, control the milling amount, adjust the radius of the lens, and control the surface shape and center at the same time Thickness, get lens base material. The outer circle of this basic material is fine-rolled to the size required by the drawing, and the error is controlled within the required tolerance. Use the equal thickness seat to modify the equal thickness dimension of the lens, control the equal thickness difference <0.005mm, and ensure the optical decentering C value. After modification, put it into the grinding jig, glue the diamond pellets on the grinding mold plate, and use the high-speed horizontal pendulum fine grinder to perform primary grinding and secondary grinding on the lens. In the process of grinding, control the primary surface defects, contr...

Embodiment 2

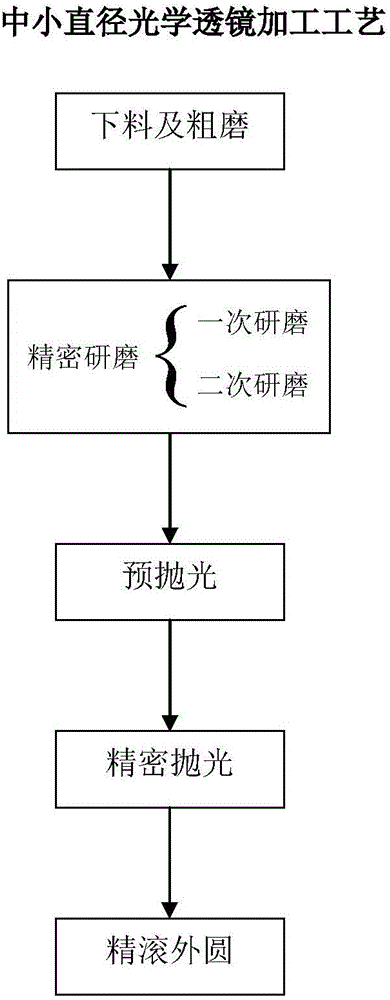

[0074] according to figure 1The process flow shown is to process small and medium-diameter optical lenses, cut the raw materials into basic square materials, rough grind to modify the thickness, rough roll the outer circle, mill the radius, control the milling amount, adjust the radius of the lens, and control the surface shape at the same time and center thickness to obtain the lens base material. Then, put the lens material into the jig for grinding and fix it, bond the diamond pellets on the grinding die plate, and use the swing fine grinder to grind the lens. In the process of grinding, control the primary surface defects, control the thickness of the center, and control the surface shape. Then, glue a polyurethane sheet on the polishing mold plate, clean the ground lens, put it into a polishing fixture, and fix it for pre-polishing. After the pre-polishing is completed, the lens is glued to the high-speed polishing mold, and the transition joint is first installed on th...

Embodiment 3

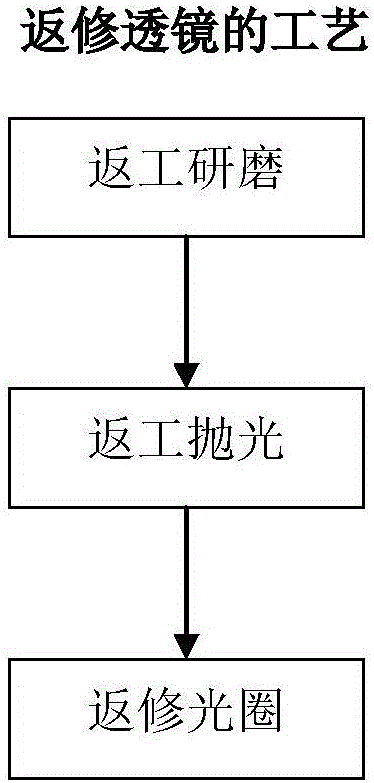

[0076] Take the reworked optical lens, put it into the polishing fixture to fix it, and then grind it on the high-speed fine grinding machine on the mold bonded with diamond pellets. After the preliminary grinding is completed, it is reworked and polished on a high-speed fine grinder, and is also directly clamped with a fixture, and the initial polishing is performed on a mold bonded with a polyurethane sheet. Then repair the aperture, and manually polish the repair ring with a polishing die to meet the requirements. Control the surface finish and aperture of the optical lens to meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com