Preparation method of crystalline silicon and crystalline silicon

A technology of crystalline silicon and Czochralski monocrystalline silicon, applied in the field of solar cell materials, can solve the problems of low minority carrier lifetime and low yield of crystalline silicon, and achieve high minority carrier lifetime, high resistance pass rate, and high resistivity pass area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of boron indium germanium co-doped polysilicon, comprising the following steps:

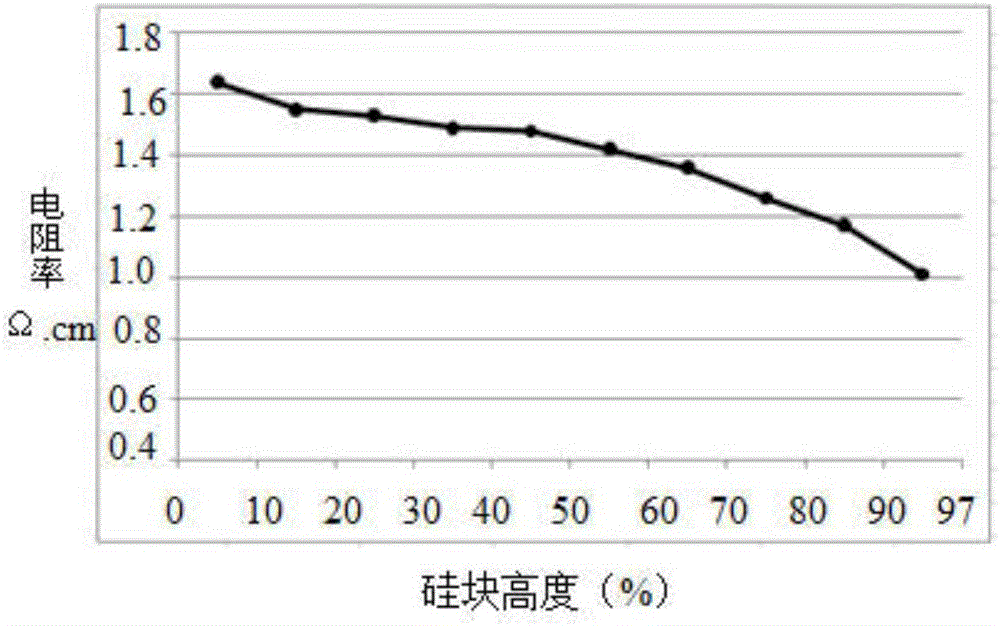

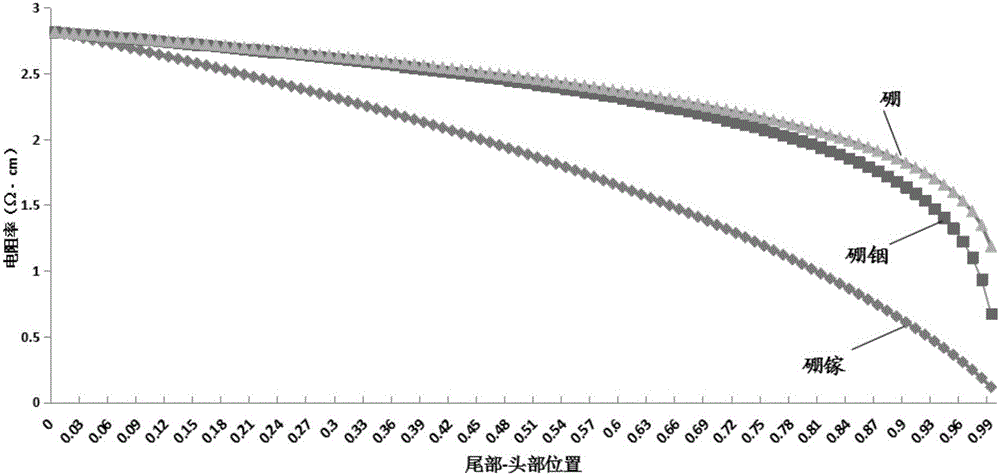

[0047] 1. Put 450kg of primary polysilicon material in a ceramic crucible, and simultaneously dope pure metal indium and pure metal germanium at 1 / 3 of the height of the crucible, wherein the masses of metal indium and metal germanium are 5g and 20g respectively, of which The atomic volume concentrations of In and Ge in the silicon material are 1.36E+17, 8.58E+10 respectively 17 atmos / cm 3 ; At 2 / 3 of the crucible height, add 60g of boron master alloy with a resistivity of 0.0026Ω.cm (in the boron master alloy, the atomic concentration of boron is 4.242E+19, the atomic volume concentration of B in the silicon material 6.52094E+15atmos / cm 3 ), so that the resistivity at 10% of the tail of the first grown polysilicon ingot is 2.78Ω·cm;

[0048] 2. Put the ceramic crucible with the above silicon material into the ingot furnace, evacuate the ingot furnace, check for lea...

Embodiment 2

[0056] A preparation method of boron indium germanium co-doped polysilicon, comprising the following steps:

[0057] 1. Put 500kg of primary polysilicon material in a ceramic crucible, and dope indium-silicon alloy and germanium-silicon alloy at the same time at 1 / 3 of the height of the crucible. Among them, the resistivity of indium-silicon alloy is 0.00002Ω·cm, and the mass is 35g. The content of indium in the alloy is 6.07E+21; the quality of the germanium-silicon alloy is 60g (the mass ratio of germanium and silicon in the germanium-silicon alloy is 1:1), wherein the atoms of In and Ge in the silicon material The volume concentration is 4E+17, 1.2E+17atmos / cm 3 , add boron powder 0.038g at 1 / 2 place of crucible height (the atomic volume concentration of B in described silicon material is 1.07E+16atmos / cm 3 ), so that the resistivity at the tail 10% of the first grown polysilicon ingot is 1.63Ω·cm;

[0058] Steps 2-3 are the same as in Embodiment 1.

[0059] Different pa...

Embodiment 3

[0062] A method for preparing a quasi-single crystal silicon ingot co-doped with boron, indium and germanium, comprising the following steps:

[0063] 1. Lay the bulk single crystal seed crystal (the crystal orientation is (100), the size is 156*156) on the bottom of the ceramic crucible, and the thickness of the seed crystal is between 10-30mm;

[0064] 2. Add 450kg of primary polysilicon material on top of the laid seed crystal, and dope pure indium and pure germanium with a weight of 50g and 100g respectively at 1 / 2 of the height of the crucible, wherein In and Ge are contained in the silicon material. Atomic volume concentrations are 1.3E+18, 4.3E+18atmos / cm 3 Doping 70g of boron master alloy at 3 / 5 of crucible height (the resistivity of boron master alloy is 0.0026, and the atomic volume concentration of B in the silicon material is 7.4E+15atmos / cm 3 ), so that the resistivity at the tail 10% of the first grown quasi-single crystal silicon ingot is 2.21Ω·cm;

[0065] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com