A medium-feeding fully synthetic wire cutting fluid

A fully synthetic, wire-cutting technology, applied in the petroleum industry, lubricating compositions, etc., to achieve the effects of improving skin adaptability, improving processing efficiency, and improving processing accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preparation method of the present invention is a conventional configuration and mixing technique, which will not be described in detail here.

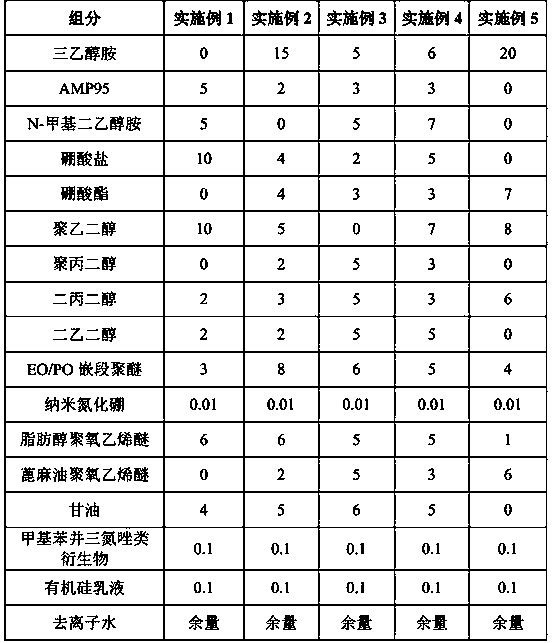

[0025] The used raw materials and consumption of embodiment 1~5 and comparative example 1~5 are as shown in table 1 and table 3:

[0026] Among them, the examples and comparative examples of the present invention have no special instructions, the molecular weight of the EO / PO block polyether is 2100-5000, and the molecular weight of the EO / PO block polyether used in Comparative Example 3 is 1600.

[0027] Table 1 The raw materials and consumption table of the embodiment

[0028]

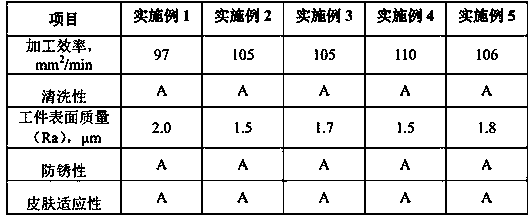

[0029] Table 2 Performance table of the cutting fluid of Examples 1-5

[0030]

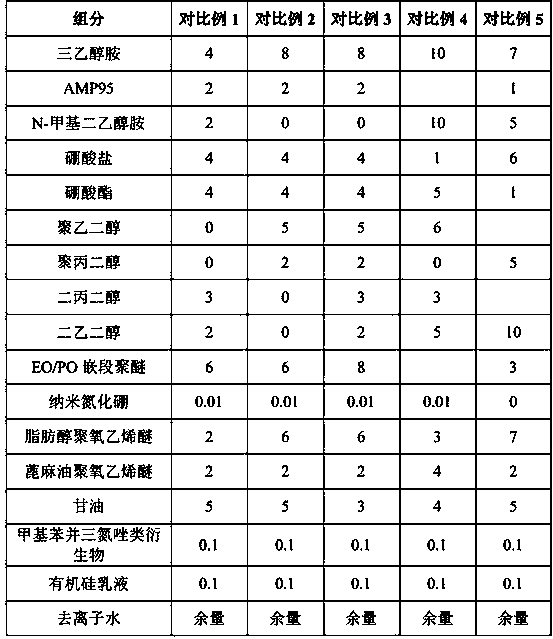

[0031] Table 3 Raw materials and dosage list of comparative examples

[0032]

[0033] Table 4 Performance Table of Cutting Fluids of Comparative Examples 1-5

[0034]

[0035] Remarks: 1, the whole formula of embodiment and comparative example is 100%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com