Method for preparing 5-nitro-2-furaldehyde and nifuratel

A technology of nitrofurfural and nitro group is applied in the field of preparation of 5-nitrofurfural and nifuratel, and can solve the problems of low yield and purity of 5-nitrofurfural, low total yield of nifuratel and easy Problems such as the formation of polymers, to achieve the effect of less impurities, shortened reaction time, and reduced side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of 5-nitrofurfural (compound 2)

[0050]

[0051] In a 100L reactor, add ethanol 60L, 5-nitrofurfural diethyl ester (compound 1) 20kg (82.25mol), 10% sulfuric acid (m / v) 1.5L, indium trichloride 910.06g (4.11mol), Heated to 80-85°C, reacted for 1.5h, concentrated under reduced pressure to remove ethanol to obtain a concentrate; the concentrate was dissolved in dichloromethane, washed three times with saturated sodium chloride, and the dichloromethane layer was collected; Dry over sodium sulfate, filter to remove the solid sodium sulfate, concentrate under reduced pressure to obtain the crude product of 5-nitrofurfural; the crude product is purified by silica gel column chromatography (eluent PE:EA=5:1), collect the target substance, and concentrate under reduced pressure , to obtain pure 5-nitrofurfural with a purity of 98% and a yield of 82%.

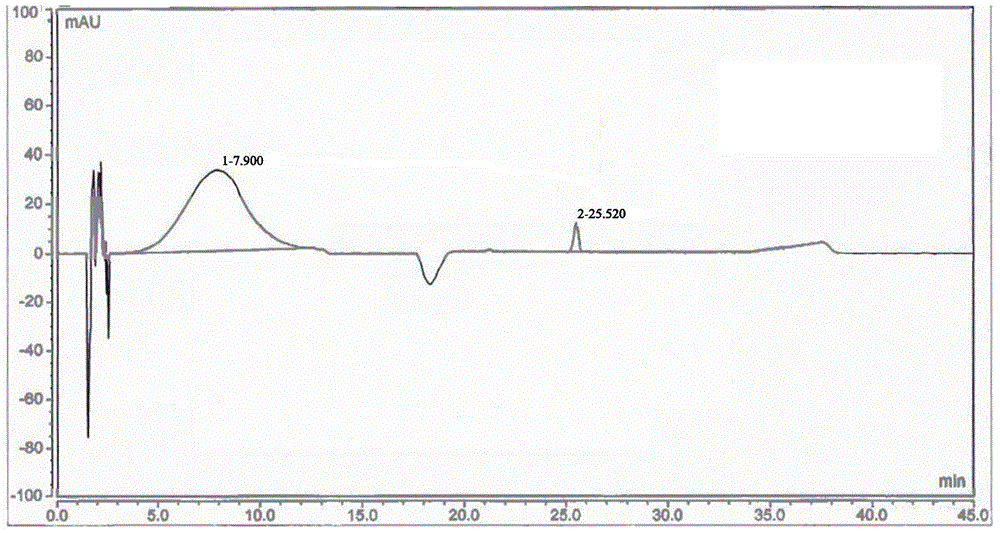

[0052] Adopt high performance liquid chromatography (HPLC) to detect the 5-nitrofurfural pure product that...

Embodiment 2

[0067] (1) Preparation of 5-nitrofurfural (compound 2)

[0068] In a 100L reactor, add ethanol 60L, 5-nitrofurfural diethyl ester (compound 1) 20kg (82.25mol), 10% sulfuric acid (m / v) 1.5L, InCl 3 / HC(OEt) 3 (indium trichloride 4.11mol, InCl 3 with HC(OEt) 3 The molar ratio is 1:0.5), heated to 78-85°C, reacted for 1h, concentrated under reduced pressure to remove ethanol, and obtained the concentrate; the concentrate was dissolved in dichloromethane, washed three times with saturated sodium chloride, and the dichloromethane was collected layer; the dichloromethane layer was dried with anhydrous sodium sulfate, filtered to remove the sodium sulfate solid, and concentrated under reduced pressure to obtain the crude product of 5-nitrofurfural; the crude product was purified by silica gel column chromatography (eluent PE:EA=5:1) , collect the target substance, and concentrate under reduced pressure to obtain the pure product of 5-nitrofurfural with a yield of 69.3%.

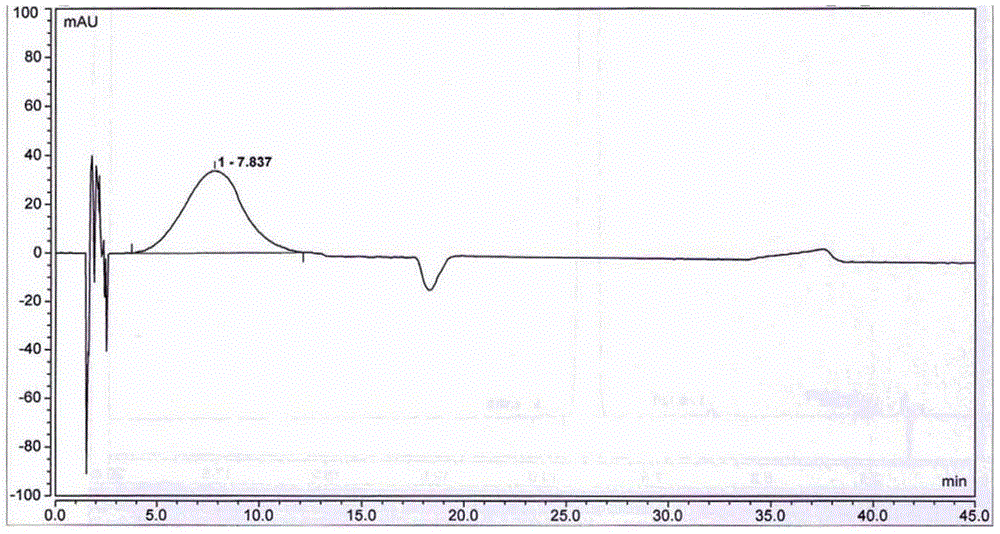

[0069] ...

Embodiment 3

[0075] (1) Preparation of 5-nitrofurfural (compound 2)

[0076] In a 100L reactor, add ethanol 60L, 5-nitrofurfural diethyl ester (compound 1) 20kg (82.25mol), 10% sulfuric acid (m / v) 1.5L, InCl 3 / HC(OEt) 3 (4.11mol, InCl 3 with HC(OEt) 3 The molar ratio is 1:1.0), heated to 78-85°C, reacted for 1.5h, concentrated under reduced pressure to remove ethanol to obtain a concentrate; the concentrate was dissolved in dichloromethane, washed three times with saturated sodium chloride, and collected dichloro The methane layer; the dichloromethane layer was dried with anhydrous sodium sulfate, filtered to remove the sodium sulfate solid, and concentrated under reduced pressure to obtain the crude product of 5-nitrofurfural; the crude product was purified by silica gel column chromatography (eluent PE:EA=5:1 ), collect the target substance, and concentrate under reduced pressure to obtain the pure product of 5-nitrofurfural with a yield of 89.2%.

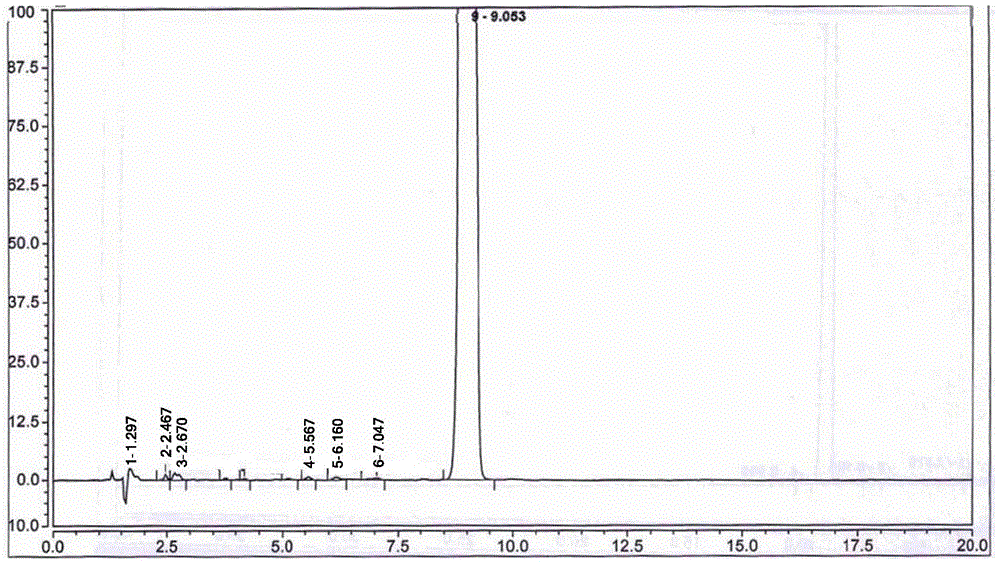

[0077] If nifuratel is prepared, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com