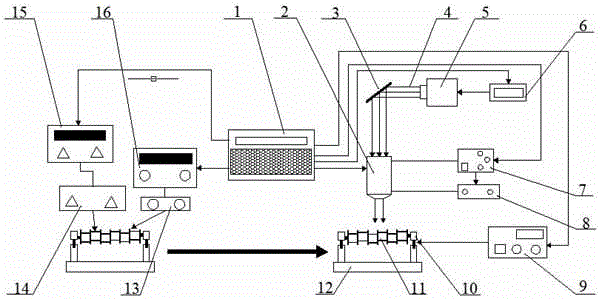

Engine crankshaft fatigue crack laser repairing and strengthening device and method

A fatigue crack and laser repair technology, applied in the coating, metal material coating process, etc., can solve the problems that the surface roughness of the crankshaft is greatly affected, only 0.1~0.8mm, and cannot be automated, so as to improve the fatigue strength and Long service life, improved wear resistance, simple and quick repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Damage site: the V journal of the crankshaft

[0024] Laser process parameters: cladding power P=5000W; spot diameter 5mm; scanning speed V=200mm / min; lap rate 50%.

[0025] Cladding powder: nickel-based ceramic alloy powder, its composition is 10% tungsten carbide, 0.3% carbon, 5% calcium fluoride, 4% boron, 3% silicon nitride, 0.6~1.0% alum, 11~14% molybdenum, 1.0~1.4% silicon, 15~18% chromium, the balance is nickel.

[0026]Detailed steps: Carry out magnetic particle flaw detection on the crankshaft of the engine to be clad, determine the position, size and shape of the crack in the V journal of the crankshaft, and use alcohol or acetone to remove the oil stains and dirt on the surface of the crankshaft; put the treated crankshaft on the five-axis linkage work On the table, after positioning it, fix and clamp it with a fixture, and control the position and angle of the crankshaft on the five-axis linkage workbench through the hydraulic telescopic rod; the central co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com