Environment-friendly composite crude oil decalcifying agent

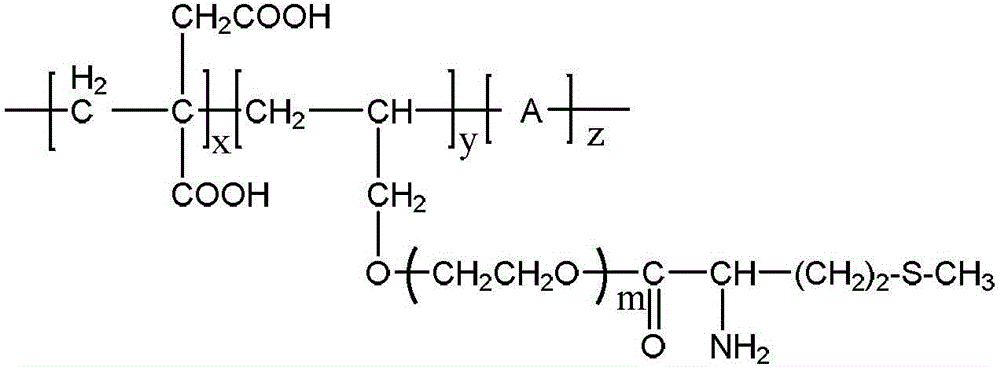

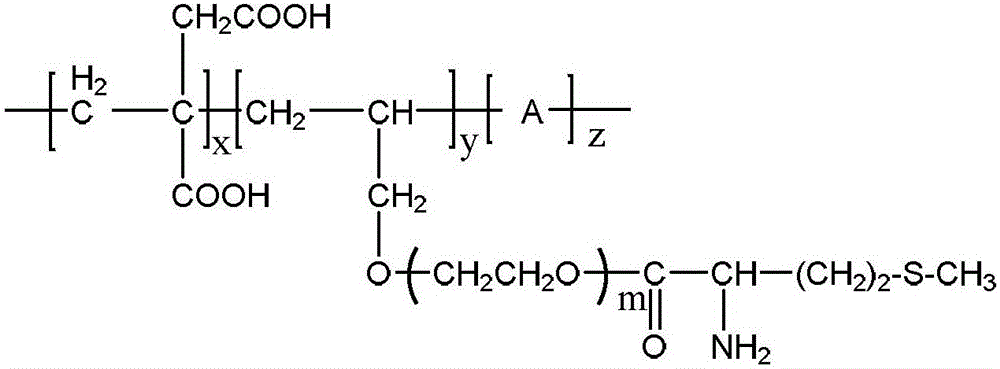

A crude oil decalcifier, an environmentally friendly technology, applied in the treatment of hydrocarbon oil, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of low calcium removal rate, corrosion of industrial equipment, difficult industrialization, etc., and achieve high-efficiency removal effect , The use process is simple, and the effect of improving the chelating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: at N 2 Add 100g of allyloxypolyethylene glycol monoether and 30g of methionine into the reaction kettle and mix them evenly at 25°C, adjust the pH to 2.5 with 10wt% hydrochloric acid, react with microwave for 0.1h, and the microwave power is 100W. After the microwave reaction, continue to react at 95°C for 2 hours, then weigh 25g of itaconic acid, 20g of maleic anhydride, 5g of mercaptoacetic acid and 300g of distilled water into the reaction kettle and mix them evenly. After cooling down to 85°C, add 50g of 4wt% ammonium persulfate dropwise Aqueous solution, after 2 hours of dripping, continue to react at 85°C for 3 hours, after dropping to 25°C, a brown-red transparent chelating agent A is obtained.

[0022] The environment-friendly compound crude oil decalcifier is prepared by mixing 35g of the above-mentioned chelating agent A, 20g of acetic acid, 20g of polyacrylic acid, 2g of sodium lauryl sulfate, 1g of urotropine, and 22g of deionized water at a room ...

Embodiment 2

[0023] Example 2: at N 2 Add 120g of allyloxypolyethylene glycol monoether and 30g of methionine into the reaction kettle and mix them evenly at 25°C, adjust the pH to 3.5 with 10wt% hydrochloric acid, react with microwave for 0.3h, and the microwave power is 300W. After the microwave reaction, continue to react at 75°C for 4 hours, then weigh 50g of itaconic acid, 30g of acrylamide, 15g of isopropanol and 350g of distilled water into the reaction kettle and mix them evenly. After heating up to 85°C, add 50g of 6wt% sodium persulfonate dropwise Aqueous solution, after 1 hour of dripping, continue to react at 85°C for 6 hours, after dropping to 25°C, a brown-red transparent chelating agent B is obtained.

[0024] Preparation of environment-friendly composite crude oil decalcifier: remove 40 g of the above-mentioned chelating agent B, 15 g of citric acid, 25 g of hydrolyzed polymaleic anhydride, 1 g of dodecyltrimethylammonium bromide, 2 g of hexamethylenetetramine, and 17 g of ...

Embodiment 3

[0025] Example 3: In N 2 Add 100g of allyloxypolyethylene glycol monoether and 35g of methionine into the reaction kettle and mix them evenly at 25°C, adjust the pH to 4.5 with 15wt% hydrochloric acid, react with microwave for 0.5h, and the microwave power is 500W. After the microwave reaction, continue to react at 80°C for 6 hours, then weigh 45g of itaconic acid, 30g of maleic anhydride, 15g of mercaptoacetic acid and 400g of distilled water into the reaction kettle and mix them evenly. After heating up to 85°C, add 50g of 8wt% persulfonic acid Sodium aqueous solution, after 1.5 hours of dropwise addition, continue to react at 85°C for 6 hours, and after lowering to 25°C, a brownish-red transparent chelating agent C is obtained.

[0026]Preparation of environment-friendly composite crude oil decalcifier: 25g of the above-mentioned chelating agent C, 15g of sulfamic acid, 25g of maleic acid acrylic acid copolymer, 1.5g of ethylene glycol butyl ether, 2.5g of thiourea, and 31g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com