A kind of polyvinyl triazole compound and preparation method thereof

A technology of polyvinyltriazole and compounds, applied in the direction of organic chemistry, which can solve the problems of poor film-forming performance and achieve the effects of improved alkali resistance and good corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

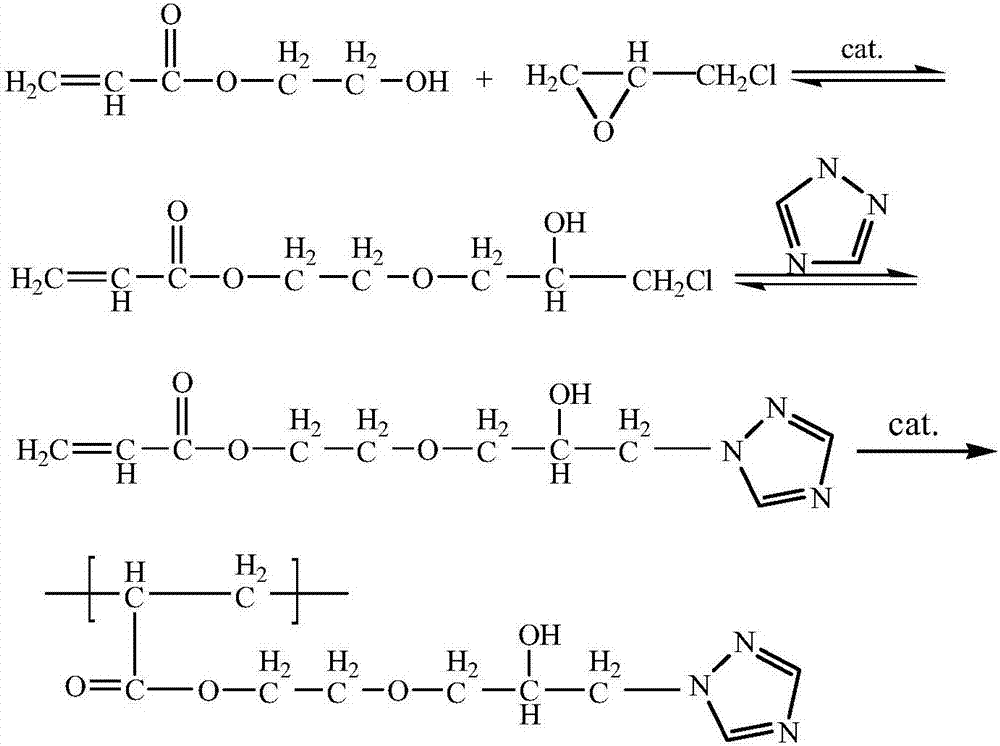

[0033] see figure 1 , The preparation method of polyvinyltriazole compound of the present invention comprises ring-opening reaction of cyclic ether, nucleophilic substitution reaction and polymerization reaction etc., concrete steps are as follows:

[0034] Step 1): In a three-neck flask equipped with a constant pressure funnel, a stirrer, and a reflux condenser, add the acetone solution of hydroxyethyl acrylate, stir well, and adjust the pH value to 3-6 with hydrochloric acid, and then set the temperature at 0°C to 50 At the temperature of ℃, slowly drop epichlorohydrin into the flask and the dropping time is 0.5h~2.5h. After the dropping, raise the temperature to 70℃~100℃ for 0.5h~2h; Wash the combined organic layers with water, distill and dry to obtain the intermediate product 1-chloro-2-hydroxyl-propyl-ethyl acrylate ether; wherein, the mass ratio of hydroxyethyl acrylate to epichlorohydrin is 1: (1~ 2), the mass fraction of the acetone solution of hydroxyethyl acrylate ...

Embodiment 1

[0038] The preparation method of polyvinyl triazole compound comprises the following steps:

[0039] Step 1): in the there-necked flask equipped with constant pressure funnel, stirrer, reflux condenser, add the acetone solution of hydroxyethyl acrylate (mass fraction is 30%), fully stir, and be 15% hydrochloric acid adjustment with mass fraction The pH value is 3, and then at 10°C, slowly add epichlorohydrin dropwise to the flask for 1 hour, and after the drop is completed, the temperature is raised to 70°C for 1.5 hours; then, the reaction mixture is cooled to room temperature, washed with water and combined with organic Layer, distilled and dried to obtain the intermediate product 1-chloro-2-hydroxyl-propyl-ethyl acrylate ether; wherein, the mass ratio of hydroxyethyl acrylate to epichlorohydrin is 1:1.2;

[0040]Step 2): The DMF solution of the product 1-chloro-2-hydroxy-propyl-acrylic acid ethyl ester ether prepared in step 1) is dropped into the reaction system with 1,2,4...

Embodiment 2

[0042] The preparation method of polyvinyl triazole compound comprises the following steps:

[0043] Step 1): in the there-necked flask equipped with constant pressure funnel, stirrer, reflux condenser, add the acetone solution of hydroxyethyl acrylate (mass fraction is 35%), fully stir, and be 20% hydrochloric acid adjustment with mass fraction The pH value is 4, and then at 0°C, slowly add epichlorohydrin dropwise to the flask for 0.5h, and after the drop, the temperature is raised to 80°C for 2h; then, the reaction mixture is cooled to room temperature, washed with water and combined The organic layer was distilled and dried to obtain the intermediate product 1-chloro-2-hydroxyl-propyl-ethyl acrylate ether; wherein, the mass ratio of hydroxyethyl acrylate to epichlorohydrin was 1:1;

[0044] Step 2): The DMF solution of the product 1-chloro-2-hydroxy-propyl-acrylic acid ethyl ester ether prepared in step 1) is dropped into the reaction system with 1,2,4-triazole and inorgan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com