A preparation method for in-situ growth of silicon carbide nanofibers and carbon fiber co-reinforced ceramic matrix composites

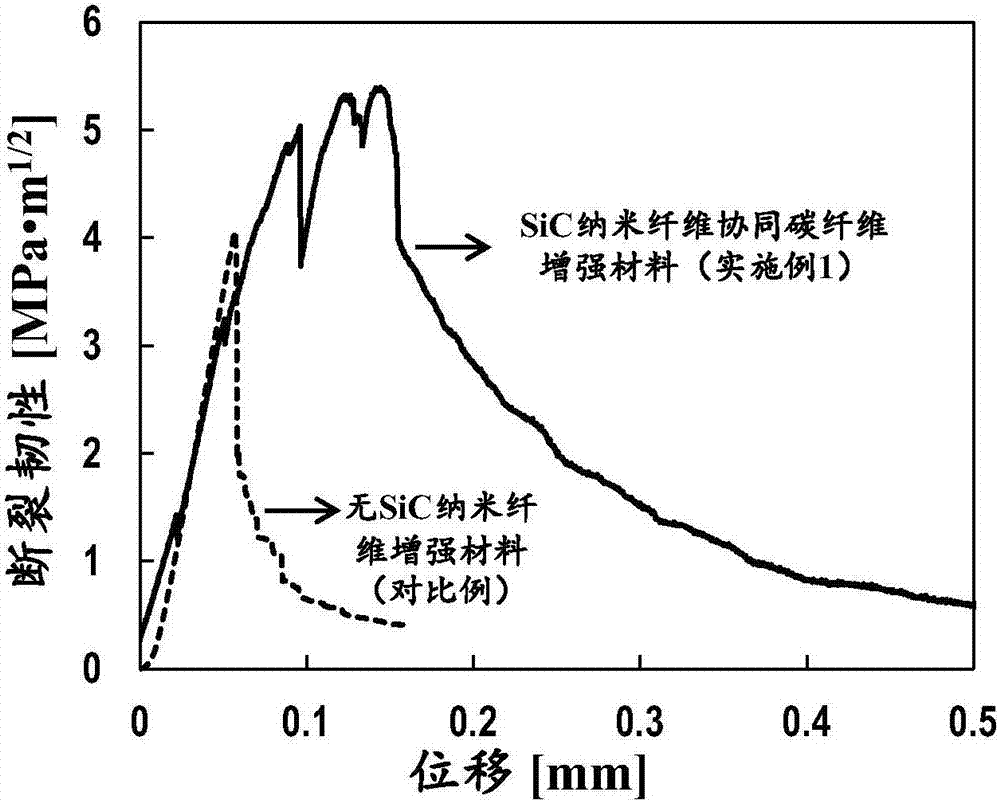

A technology of in-situ growth of nanofibers, which is applied in the field of ceramic matrix composites, can solve the problems of low purity of silicon carbide nanofibers, achieve the effects of improving strength, toughness and high temperature environment stability, simple equipment, and increasing resistance to crack propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

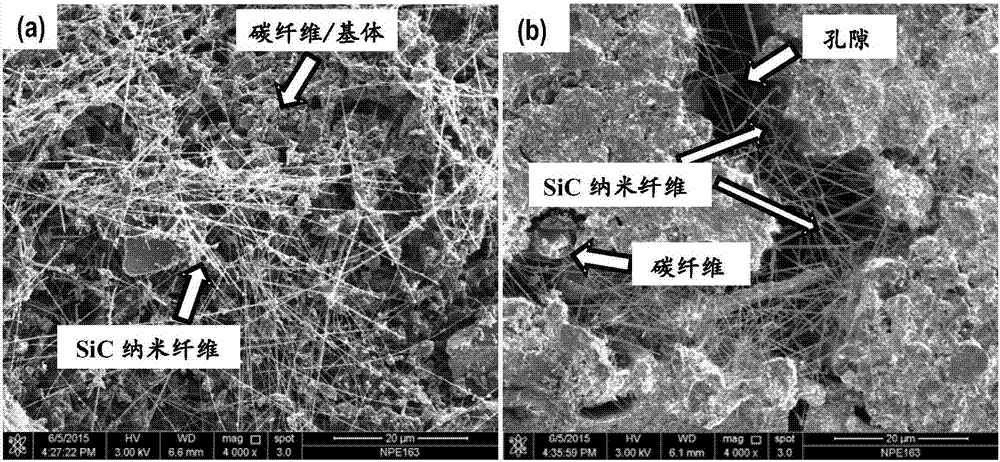

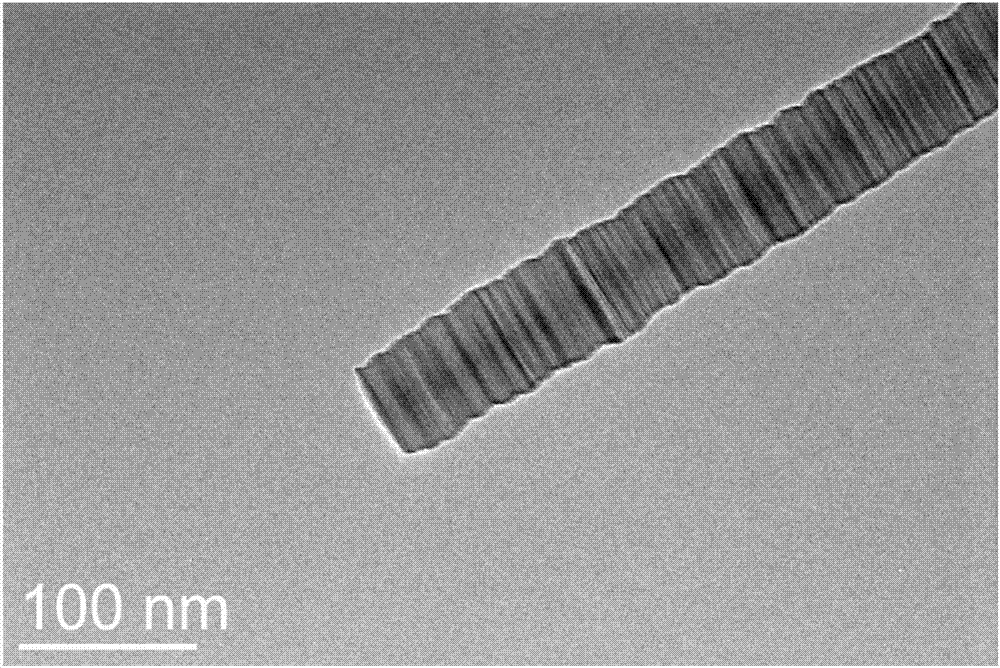

[0037] A method for preparing in-situ growth of silicon carbide nanofibers synergistically with carbon fiber co-increased ceramic matrix composites, comprising the following steps:

[0038] a) Weigh 75g of silicon powder and 100g of silicon dioxide powder (purity: 99.9%), uniformly mix through high-energy ball milling to make a fine powder slurry, evaporate and dry the slurry on a rotary evaporator, and then grind to obtain a mixed powder material.

[0039] b) Weigh 100g of the mixed powder obtained in step a, place it on the bottom of the graphite crucible, place a porous graphite support at the middle end of the crucible, then place 50g of carbon / carbon porous material on the porous graphite support, and finally take A graphite lid covers the graphite crucible.

[0040] c) Place the device in step b in a tube furnace, first evacuate it to within 10Pa, then fill it with high-purity argon (purity ≥ 99.99%; oxygen content ≤ 10PPM) at a flow rate of 15cc / min, with 10 The heati...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is that in step c, when heating to 1500° C., the holding time is 40 minutes, and other steps and test parameters are the same.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is that in step c, when heating to 1600° C., the holding time is 40 minutes, and other steps and test parameters are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com