Method for diffusion connection of high-niobium TiAl alloy by using composite metal foil

A composite metal and diffusion bonding technology, which is applied in metal processing equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of poor joint quality, complicated process, and long time consumption, so as to avoid deformation and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

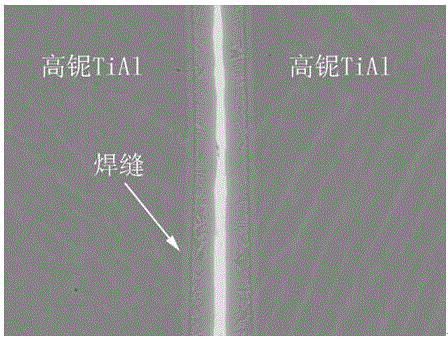

Image

Examples

Embodiment 1

[0021] In this embodiment, a method of using composite metal foil to diffusely connect high-niobium TiAl alloys is carried out according to the following steps: 1. Use 600#, 800#, 1200#, 1500#, and 2000# for the connection surface of the high-niobium TiAl alloy to be welded successively. #Grinding with metallographic sandpaper, then polishing with 0.5μm polishing paste, and ultrasonically cleaning the base material to be welded and the middle layer of the composite foil in acetone for 10 minutes;

[0022] 2. Place the base metal after ultrasonic cleaning and the foil with a thickness of 10-30 μm in the order of high-niobium TiAl / Ti / Nb / Ti / high-niobium TiAl, and apply an axial pressure of 15-30 MPa to the connection sample; When implementing diffusion connection, vacuum the chamber of the vacuum diffusion welding machine to 5×10 -3 After Pa, start heating with electricity, the heating rate is 15-30°C / min, heat to 1100-1300°C, and hold the temperature for 1-3 hours;

[0023] 3. ...

Embodiment 2

[0025] Embodiment 2: The difference between this embodiment and the first embodiment is that the thickness of the foil used in the second step is 20 μm Ti foil and 15 μm Nb foil. Others are the same as in Example 1.

Embodiment 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the heating rate used in step 2 is 20° C. / min. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com