Aluminum Alloy Ultrasonic Resistance Composite Butt Brazing Method

A brazing method and aluminum alloy technology, which is applied in the field of aluminum alloy brazing, can solve the problems that the welding current passes through the workpiece and the test bench, the base, affects the welding process parameters, and the welding joint area is small, so as to achieve compact structure and improve joint welding. The combination rate and the effect of improving the strength of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

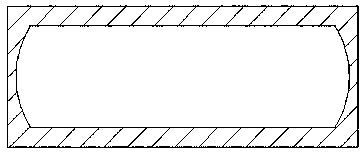

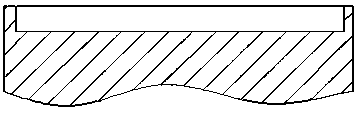

[0028] As shown in Figures 4-6, the insulating sliding welding device of the present invention includes a sliding part, an insulating part and a base 1. The base 1 and the guide rail 2 are connected by bolts. The sliding part includes the guide rail 2, the upper slider 3 and the lower slider 3'. There are the upper slider 3 and the lower slider 3' on the guide rail 2. The right surfaces of the sliders 3 and 3' m 3 Flat, with substrate 1 right surface M 1 parallel. The insulating part comprises an upper insulating plate 4, a lower insulating plate 4' and an insulating cap 6, and the axis OO' of the insulating cap 6 is connected to the right surface M of the insulating plate 4 4 The face is vertical.

[0029] In the above insulated sliding welding device, the upper slider 3 and the lower slider 3' are respectively provided with four positioning internal threads, and the upper workpiece 5, the upper insulating plate 4, the lower workpiece 5', and the lower insulating plate are...

Embodiment , Embodiment 2

[0033] Embodiment of the method of the present invention, embodiment 2: the resistance brazing of aluminum alloy:

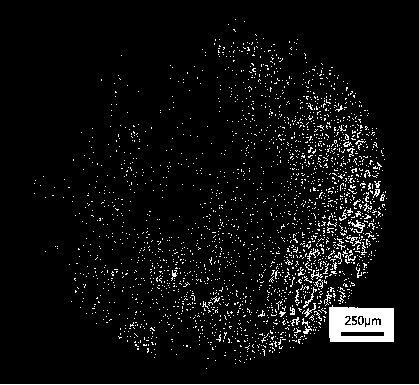

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the aluminum alloy end face is processed, and the base metal is installed on the figure 2 On the jig shown, bolt the electrode to the base metal. Use sheet-shaped brazing filler metal to be placed in the groove to be welded, and the thickness of the brazing filler metal is 0.3mm. Set the resistance brazing parameters, the welding current is 2.5kA in the first stage, the welding time is 50CYC, the ultrasonic wave is applied for 6s, the welding pressure is 1MPa, the resistance brazing is started, and then the weldment is allowed to cool naturally.

[0035] The material is aluminum alloy, the end face size is 8×20mm, the groove depth is 0.15mm, and the solder is Al-Si-Mg (mass percentage: Si: 9-10.5% Mg: 1-2% Cu, Ni≤0.45% ), the thickness is 0.3mm, and the size is 6×16mm.

[0036]figure 1 S...

Embodiment , Embodiment 3

[0037] Embodiment of the method of the present invention, embodiment 3: the resistance brazing of aluminum alloy:

[0038] Such as figure 2 As shown, the aluminum alloy end face is processed, the base metal is installed on the fixture, and the electrode and the base metal are connected with bolts. The sheet-shaped brazing material is placed in the groove to be welded, and the thickness of the brazing material is 1mm. Set the parameters of resistance brazing. The welding current in the first stage is 2.5kA, the welding time is 50CYC, and the power is stopped for 50CYC. Resistance brazing followed by allowing the weldment to cool naturally.

[0039] The base material is aluminum alloy, the end face size is 8×30mm, the groove depth is 0.5mm, and the solder is Al-Si-Mg (mass percentage: Si: 9-10.5% Mg: 1-2% Cu, Ni≤ 0.45%), the thickness is 1mm, and the size is 6×16mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com