Method for preparing lumpy nitrogenous multistage-pore-passage charcoal material

A carbon material, multi-level pore technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of complex powder structure molding process, complex process route, difficult to have mass transfer rate, etc., and achieve good cycle stability. , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 1ml tetraethyl orthosilicate (TEOS) and dissolve in 3ml DMF, stir evenly to obtain a colorless transparent solution, meanwhile, prepare 125gL -1 Add 1.5ml of polyacrylonitrile-DMF solution, and add it into TEOS-DMF solution, stir well. Add 0.01728 g of 1,6-hexanediamine solution (the solvent is ethanol and water at 1:1) while stirring at 80°C, and stir evenly. The reaction system was sealed, turned to 90°C for aging for 12 hours, and dried to obtain a block polymer. And put it under the protection of inert atmosphere, 3°C min -1 Raise the temperature to 400°C, keep the temperature constant for 60 minutes, then raise the temperature to 800°C at the same heating rate, and keep the temperature constant for 120 minutes to obtain a bulk carbon-silicon oxide composite with shape retention. Use 8% sodium hydroxide solution in water and ethanol (3:1 volume ratio) to remove silicon at 50°C for 24h, then wash with water and dry at 90°C for 24h.

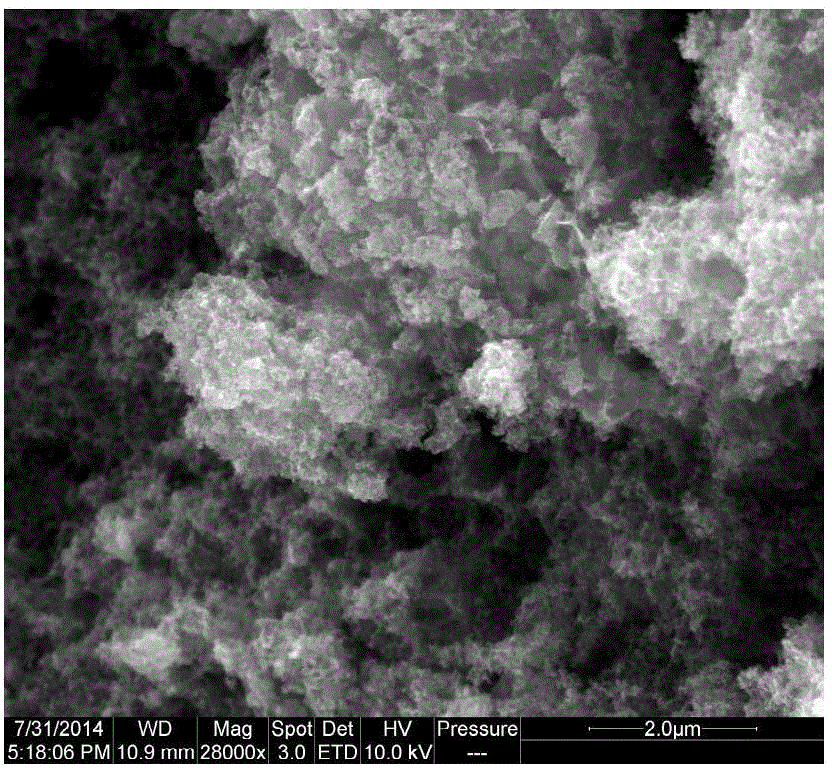

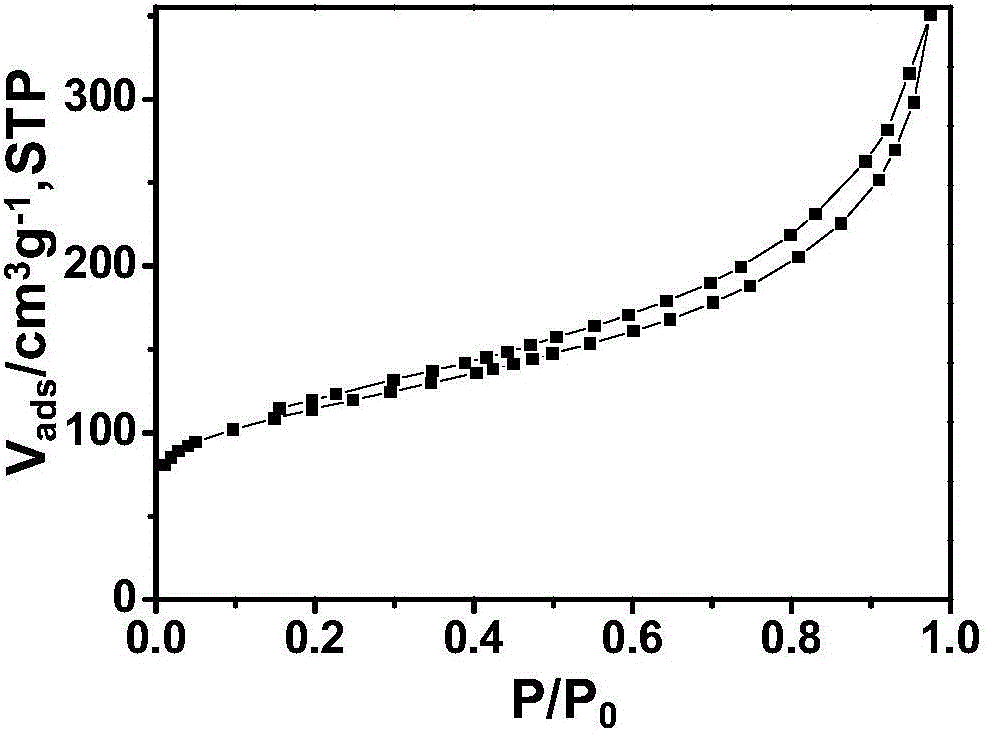

[0026] The scanning elect...

Embodiment 2

[0028] Take 1.2ml tetraethyl orthosilicate (TEOS) and dissolve in 3ml DMF, stir evenly to obtain a colorless transparent solution, meanwhile, prepare 100gL -1Add 5ml of polyacrylonitrile-DMF solution, and add it into TEOS-DMF solution, stir evenly. Add 800ulNH 3 .H 2 O, stir well. Seal the reaction system, transfer it to a certain temperature for aging for 12 hours, and after natural cooling, perform solvent replacement (3 times with ethanol, 3 times with n-hexane and 3 times with trimethylchlorosilane), and dry at 50°C to obtain block polymerization things. And put it under the protection of inert atmosphere, 3°C min -1 Raise the temperature to 400°C, keep the temperature constant for 60 minutes, then raise the temperature to 800°C at the same heating rate, and keep the temperature constant for 120 minutes to obtain a bulk carbon-silicon oxide composite with shape retention. Use 8% sodium hydroxide solution in water and ethanol (3:1 volume ratio) to remove silicon at 50°...

Embodiment 3

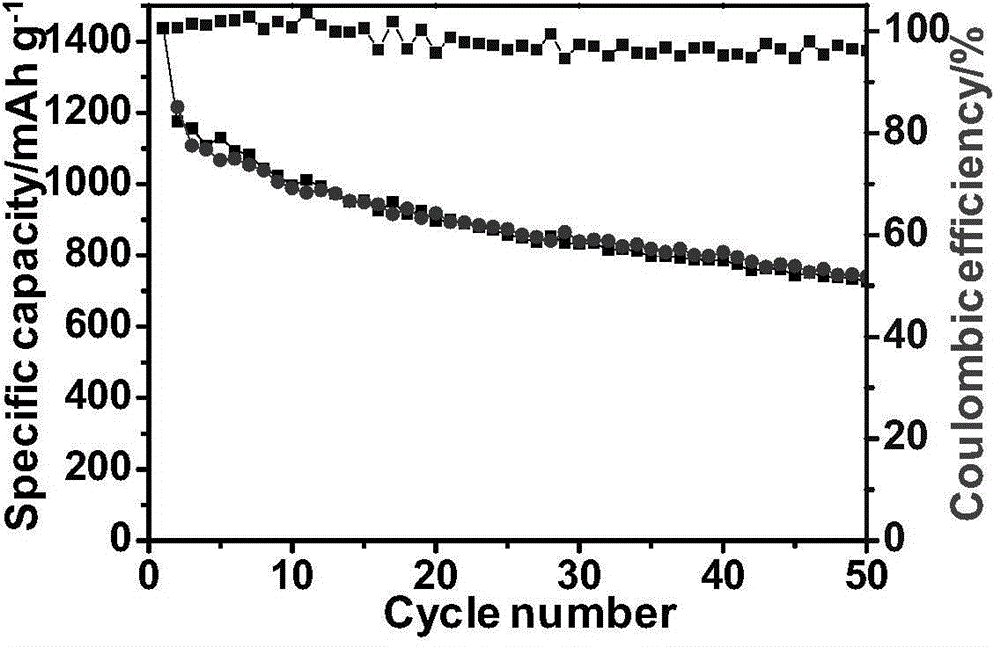

[0030] Taking the bulk nitrogen-containing porous carbon prepared in Example 1, a carbon-sulfur composite with a sulfur content of 44% was prepared. Grind the carbon-sulfur composite, acetylene black, and PVDF at a mass ratio of 8:1:1, add an appropriate amount of N-methylpyrrolidone, mix well, and coat the aluminum foil to prepare a pole piece. The electrode sheet (size 1cm×1cm, about 25-50μm thick, containing 0.5-1.5mg of sulfur) was used as the positive electrode, and the lithium sheet was used as the negative electrode to assemble a button battery, and its electric capacity at a rate current density of 0.1C was tested. chemical properties. image 3 is the electrochemical cycling stability curve of the material. The first discharge specific capacity is 1400mAhg -1 , the specific capacity reached 750mAhg after 50 cycles at a current density of 0.1C -1 Above, has good cycle stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesopore | aaaaa | aaaaa |

| macropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com